Abstract

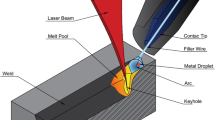

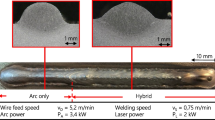

Laser–arc hybrid welding (LAHW) is an advanced welding method that combines arc welding and laser welding and can achieve deep penetration and the reduction of welding deformation compared with conventional arc welding. As with other welding techniques, it is common to target the flat position (PA) as the welding position. However, the expansion of the applicable positions enables the application of high-quality welded joints fabricated by LAHW to many welded joints in large steel structures. This study used the LAHW system with a robot manipulator to establish weldability in the horizontal position (PC) and the vertical-up position (PF) to expand the applicable range of LAHW in large steel structures. Suitable LAHW conditions for fabricating the butt-welded joint with a welding length of 1,000 mm for these positions were established through various investigations, including molten pool observation. Finally, the quality of these joints was evaluated in accordance with the laser–arc hybrid welding guidelines (ClassNK) of Nippon Kaiji Kyokai, and it was confirmed that the joints satisfy the required standards.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Lan LY, Kong XW, Qiu CL, Zhao DW (2016) Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater Des 90:488–498. https://doi.org/10.1016/j.matdes.2015.10.158

Shi MH, Zhang PY, Zhu FX (2014) Toughness and microstructure of coarse grain heat affected zone with high heat input welding in Zr-bearing low carbon steel. ISIJ Int 54(1):188–192. https://doi.org/10.2355/isijinternational.54.188

Farrokhi F, Nielsen SE, Schmidt RH et al (2015) Effect of cut quality on hybrid laser arc welding of thick section steels. Phys Procedia 78:65–73. https://doi.org/10.1016/j.phpro.2015.11.018

Farrokhi F, Kristiansen M (2016) A practical approach for increasing penetration in hybrid laser-arc welding of steel. Phys Procedia 83:577–586. https://doi.org/10.1016/j.phpro.2016.08.060

Bunaziv I, Dørum C, Nielsen SE et al (2020) Laser-arc hybrid welding of 12- and 15-mm thick structural steel. Int J Adv Manuf Technol 107(5-6):2649–2669. https://doi.org/10.1007/s00170-020-05192-2

Uchino I, Uemura T, Gotoh K (2021) A study on adopting λ-shape groove for laser-arc hybrid welding to construct thick plate butt welded joints. Weld Int 34(7-9):357–371. https://doi.org/10.1080/09507116.2021.1936931

Graudenz M, Baur M (2013) Applications of laser welding in the automotive industry. In: Katayama S (ed) Handbook of Laser Welding Technologies. Woodhead Publishing Limited, London, pp 555–574. https://doi.org/10.1533/9780857098771.4.555

Wang H (2013) Applications of laser welding in the railway industry. In: Katayama S (ed) Handbook of Laser Welding Technologies. Woodhead Publishing Limited, London, pp 575–595. https://doi.org/10.1533/9780857098771.4.575

Reitemeyer D, Schultz V, Syassen F et al (2013) Laser welding of large scale stainless steel aircraft structures. Phys Procedia 41:106–111. https://doi.org/10.1016/j.phpro.2013.03.057

Koga H, Goda H, Terada S et al (2010) First application of hybrid laser-arc welding to commercial ships. Mitsubishi Heavy Ind Tech Rev 47(3):59–64

Roland F, Manzon L, Kujala P et al (2004) Advanced joining techniques in European shipbuilding. J Ship Prod Des 20(3):200–210. https://doi.org/10.5957/jsp.2004.20.3.200

Unt A, Salminen A (2015) Effect of welding parameters and the heat input on weld bead profile of laser welded T-joint in structural steel. J Laser Appl 27(S2):S29002. https://doi.org/10.2351/1.4906378

Trichin G, Kuznetsov M, Tsibulskiy I, Firsova A (2017) Hybrid laser-arc welding of the high-strength shipbuilding steels: equipment and technology. Phys Procedia 89:156–163. https://doi.org/10.1016/j.phpro.2017.08.005

Femandes CA, do Vale NL, Santos TFD, Urtiga SL (2020) Investigation of transverse shrinkage and angular distortion caused by hybrid laser-arc welding. Int J Adv Manuf Technol 107(11-12):4705–4711. https://doi.org/10.1007/s00170-020-05343-5

ISO 6947 (2019) Welding and allied processes - welding positions

Chen YB, Feng JC, Li LQ et al (2013) Effects of welding positions on droplet transfer in CO2 laser-MAG hybrid welding. Int J Adv Manuf Technol 68(5-8):1351–1359. https://doi.org/10.1007/s00170-013-4926-9

Wang K, Jiao XD, Zhu JL et al (2021) Research on the effect of weld groove on the quality and stability of laser-MAG hybrid welding in horizontal position. Weld World. https://doi.org/10.1007/s40194-021-01125-z Accessed 08 June 2021

Zou JL, Yang WX, Wu SK et al (2016) Effect of plume on weld penetration during high-power fiber laser welding. J Laser Appl 28(2):022003. https://doi.org/10.2351/1.4940148

Nippon Kaiji Kyokai (2016) Guidelines on laser-arc hybrid welding (Ver. 3)

Kataoka T, Ikeda R, Yasuda K (2007) Development of ultra-low spatter CO2 gas-shielded arc welding process “J-STAR® Welding”. JFE Tech Rep 10:31–34

Wahba M, Mizutani M, Katayama S (2016) Single pass hybrid laser-arc welding of 25 mm thick square groove butt joints. Mater Des 97:1–6. https://doi.org/10.1016/j.matdes.2016.02.041

Guo W, Liu Q, Francis JA et al (2015) Comparison of laser welds in thick section S700 high-strength steel manufactured in flat (1G) and horizontal (2G) positions. CIRP Ann 64(1):197–200. https://doi.org/10.1016/j.cirp.2015.04.070

Sun JH, Feng K, Zhang K et al (2017) Fiber laser welding of thick AISI 304 plate in a horizontal (2G) butt joint configuration. Mater Des 118:53–65. https://doi.org/10.1016/j.matdes.2017.01.015

Hosoi K, Hirata Y, Ogino Y, Kouno H (2016) MAG welding phenomena with titania-based flux cored wire in vertical upward position (in Japanese). Sumato Purosesu Gakkaishi (Journal of Smart Processing) 5(1):95–100. https://doi.org/10.7791/jspmee.5.95

ISO 5817 (2003) Welding - fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) - quality levels for imperfections

Adamczuk PC, Machado IG, Mazzaferro JAE (2017) Methodology for predicting the angular distortion in multi-pass butt-joint welding. J Mater Process Technol 240:305–313. https://doi.org/10.1016/j.jmatprotec.2016.10.006

Acknowledgements

We would like to express our gratitude to all related parties for their cooperation in NDT and mechanical tests and provision or preparation of test materials. This study was supported by JFE Steel Corporation through the provision of KC-550, which is a welding wire for J-STAR® Welding. We thank Edanz (https://jp.edanz.com/ac) for editing a draft of this manuscript.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XV - Design, Analysis, and Fabrication of Welded Structures

Rights and permissions

About this article

Cite this article

Uemura, T., Gotoh, K. & Uchino, I. Expansion of laser–arc hybrid welding to horizontal and vertical-up welding. Weld World 66, 495–506 (2022). https://doi.org/10.1007/s40194-021-01236-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01236-7