Abstract

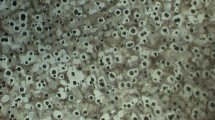

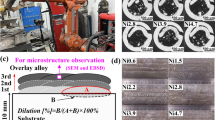

Severe abrasive wear of drill pipe and casing often occurs in exploration drilling operations. To achieve the surface enhancement of the drilling components in terms of abrasive wear resistance, various flux-cored wires (FCWs) containing multiple alloying elements were developed, and the Fe-based hardfacing layers were developed by metal active-gas (MAG) welding process. The macro morphology, microstructure, and phase composition of the alloys were characterized by using OM, SEM, XRD, and EDS methods, while the wear resistance performance was measured by using an abrasion tester. The results showed that the hardfacing layer prepared by Fe-Cr-C FCW is hypoeutectic that mainly consisted of austenite matrix and (Fe,Cr)7C3-type carbides. On this basis, a higher C content in combination with Nb, Ti, and B additives resulted in the microstructure comprised of martensite-based matrix and the precipitations of (Nb,Ti)C and Fe2B hard phases. With the removal of Cr, the further addition of Nb, Ti, and B, the hard phases change from particles to bulk and lath shapes. The hard phases with higher microhardness values than the matrix contributed to an improved Rockwell hardness and a highly decreased wear weight loss of hardfacing layer. Accordingly, the wear mechanism changed from severe plastic fracture to micro-cutting going with a slight brittle micro-peeling. The interlaced distribution of (Nb,Ti)C and Fe2B provided a stable skeleton that enables an further enhanced abrasive wear resistance.

Similar content being viewed by others

References

Durmuş H, Çömez N, Gül C, Yurddaşkal M, Yurddaşkal M (2018) Wear performance of Fe-Cr-C-B hardfacing coatings: Dry sand/rubber wheel test and ball-on-disc test. Int J Refract Met H 77:37–43

Yüksel N, Sahin S (2014) Wear behavior-hardness-microstructure relation of Fe-Cr-C and Fe-Cr-C-B based hardfacing alloys. Mater Des 58:491–498

Gualco A, Marini C, Svoboda H, Surian E (2015) Wear resistance of Fe-based nanostructured hardfacing. Procedia Mater Sci 8:934–943

Cabrol E, Boher C, Vidal V, Rézaï-Aria F, Touratier F (2015) Plastic strain of cobalt-based hardfacings under friction loading. Wear 330–331:354–363

Chakraborty G, Kumar N, Das CR, Albert SK, Bhaduri AK, Dash S, Tyagi AK (2014) Study on microstructure and wear properties of different nickel base hardfacing alloys deposited on austenitic stainless steel. Surf Coat Technol 244:180–188

Bakshi SR, Harimkar SP (2015) Surface engineering for extreme conditions. JOM 67:1526–1527

Sapate SG, Ramarao AV (2006) Erosive wear behaviour of weld hardfacing high chromium cast irons: effect of erodent particles. Tribol Int 39:206–212

Chung RJ, Tang X, Li DY, Hinckley B, Dolman K (2009) Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe–25wt.%Cr–4wt.%C. Wear 267:356–361

Liu HY, Song ZL, Cao Q, Chen SP, Meng QS (2016) Microstructure and properties of Fe-Cr-C hardfacing alloys reinforced with TiC-NbC. J Iron Steel Res Int 23:276–280

Buytoz S, Yildirim MM, Eren H (2005) Microstructural and microhardness characteristics of gas tungsten arc synthesized Fe–Cr–C coating on AISI 4340. Mater Lett 59:607–614

Buytoz S (2006) Microstructural properties of M7C3 eutectic carbides in a Fe–Cr–C alloy. Mater Lett 60:605–608

Sapate SG, Ramarao AV (2006) Effect of carbide volume fraction on erosive wear behaviour of hardfacing cast irons. Wear 256:774–786

Wang Y, Gou JF, Chu RQ, Zhen DX, Liu SY (2016) The effect of nano-additives containing rare earth oxides on sliding wear behavior of high chromium cast iron hardfacing alloys. Tribol Int 103:102–112

Liu S, Shi ZJ, Xing XL, Ren XJ, Zhou YF, Yang QX (2020) Effect of Nb additive on wear resistance and tensile properties of the hypereutectic Fe-Cr-C hardfacing alloy. Mater Today Commun 24:101232

Liu S, Zhou YF, Xing XL, Wang JB, Yang QX (2017) Refining effect of TiC on primary M7C3 in hypereutectic Fe-Cr-C harden-surface welding coating: experimental research and first-principles calculation. J Alloy Comp 691:239–249

Hayat MD, Singh H, He Z, Cao P (2019) Titanium metal matrix composites: an overview Compos. Part A-Appl S 121:418–438

Zhang YC, Song RB, Pei Y, Wen E, Zhao ZY (2020) The formation of TiCeNbC core-shell structure in hypereutectic high chromium cast iron leads to significant refinement of primary M7C3. J Alloy Comp 824:153806

Qi XW, Jia ZN, Yang QX, Yang YL (2011) Effects of vanadium additive on structure property and tribological performance of high chromium cast iron hardfacing metal. Surf Coat Technol 205:5510–5514

Correa EO, Alcântara NG, Valeriano LC, Barbedo ND, Chaves RR (2015) The effect of microstructure on abrasive wear of a Fe–Cr–C–Nb hardfacing alloy deposited by the open arc welding process. Surf Coat Technol 276:479–484

Chung RJ, Tang X, Li DY, Hinckley B, Dolman K (2009) Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe-25wt.% Cr-4wt.% C. Wear 267:356–361

Yang K, Bao YF, Jiang YF (2017) Formation mechanism of titanium and niobium carbides in hardfacing alloy. Rare Met 36:640–644

Liu DS, Liu RP, Wei YH, Ma Y, Zhu K (2013) Microstructure and wear properties of Fe-15Cr-2.5Ti-2C-xB wt. % hardfacing alloys. Appl Surf Sci 271:253–259

Lőrinczi J, Králik G, Kovács M, Horváth Á (2003) Investigation of the relationships between the material properties and the process parameters of the boron micro-alloyed quenched and tempered steels. Mater Sci Forum 414–415:267–274

Sadeghi F, Najafi H, Abbasi A (2017) The effect of Ta substitution for Nb on the microstructure and wear resistance of a Fe-Cr-C hardfacing alloy. Surf Coat Technol 24:85–91

Li QT, Lei YP, Fu HG (2014) Growth mechanism, distribution characteristics and reinforcing behavior of (Ti, Nb)C particle in laser cladded Fe-Based composite coating. App Surf Sci 316:610–616

Kan WH, Bhatia V, Dolman K, Lucey T, Tang XH, Chang L, Proust G, Cairney J (2018) A study on novel AISI 304 stainless steel matrix composites reinforced with (Nb0.75, Ti0.25)C. Wear 398:220–226

Filipovic M, Kamberovic Z, Korac M, Gavrilovski M (2013) Microstructure and mechanical properties of Fe–Cr–C–Nb white cast irons. Mater Des 47:41–48

Acknowledgements

The authors gratefully acknowledged a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I - Additive Manufacturing, Surfacing, and Thermal Cutting

Rights and permissions

About this article

Cite this article

Chen, J., Xie, W., Liu, R. et al. Microstructure and wear resistance of Fe-based hardfacing layer prepared by flux-cored wire feeding MAG welding process. Weld World 66, 175–185 (2022). https://doi.org/10.1007/s40194-021-01209-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01209-w