Abstract

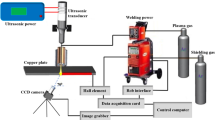

Advances in the dynamic response of welding power sources have allowed the use of pulsed current at frequencies above 20 kHz. However, the effects of pulsing the welding current at these high-frequency levels are not well known, especially those associated with the voltaic arc. Thus, the aim of this study was to carry out experimental research on a pulsating welding current at ultra-high frequencies focusing on two important voltaic arc parameters in gas tungsten arc welding processes: arc voltage and arc stagnation pressure. The tests were performed with a welding current pulsed at frequencies of 20 to 80 kHz and amplitudes of 0 to 50 A. The results indicated that pulsing the current at ultra-high frequencies leads to a reduction in the average arc voltage, increasing the stagnation pressure and the arc constriction. Regarding the weld bead dimensional aspects, greater values of width and penetration were obtained when the high-frequency current pulsation was applied.

Similar content being viewed by others

Data availability

Not applicable.

References

Cook GE, Eassa HE-DEH (1985) The effect of high-frequency pulsing of a welding arc. IEEE Trans Ind Appl (5):1294–1299

Qiu, Ling et al (2007) High-frequency pulse modulated variable polarity welding power and its arc pressure. Trans China Weld Inst 28(11):81

Ling Q, Chunli Y, Sanbao L (2007) Technology properties of variable polarity arc welding with high frequency pulsed current. Welding and Joining 7

Qi BJ et al (2013) The effect of arc behavior on weld geometry by high-frequency pulse GTAW process with 0Cr18Ni9Ti stainless steel. Int J Adv Manuf Technol 66(9–12):1545–1553

Wang J, Kusumoto K, Nezu K (2004) Investigation into micro-tungsten inert gas arc behaviour and weld formation. Sci Technol Weld Join 9(1):90–94

Zhao JR, Li YD (1989) Control over arc of pulsed high frequency TIG welding and high frequency effect. Journal of Tianjin University 3:25–32

Yamaota T, Shimada W, Gotoh T (1979) Characteristics of high frequency pulsed DC TIG welding process. Weld Res Abroad 25(10):16–22

Saedi HR, Unkel W (1988) Arc and weld pool behavior for pulsed current GTAW. Weld J 67(11):247

Stoeckinger GR (1973) Pulsed DC high frequency GTA welding of aluminum plate. Weld J 52(12):558

He L et al (2006) Ultrasonic generation by exciting electric arc: a tool for grain refinement in welding process. Appl Phys Lett 89(13):131504

Sun QJ et al (2009) Penetration increase of AISI 304 using ultrasonic assisted tungsten inert gas welding. Sci Technol Weld Join 14(8):765–767

Baoqiang C, Bojin Q, Xingguo Z (2009) Ultrafast-convert hybrid pulse square-wave variable polarity TIG arc behavior. Journal of Beijing University of Aeronautics and Astronautics 35(8):1013

Qi BJ et al (2012) The effect of hybrid ultrasonic pulse current parameters on VPTIG arc pressure and weld formation. Mater Sci Forum 704:770–774

Cong B, Qi B, Zhou X (2009) TIG arc behavior of ultrafast-convert high-frequency variable-polarity square wave. Trans China Weld Inst 30(6)

Wang Y, Chen M, Wu C (2020) High-frequency pulse-modulated square wave AC TIG welding of AA6061-T6 aluminum alloy. Welding in the World 64(10):1749–1762

Wang JJ, Hong XO (2011) Research on twin-arc TIG welding with ultrasonic excitation and its effect to weld. Key Eng Mater 450:300–303

Cunha, Tiago Vieira da. Desenvolvimento e avaliação de tecnologia para soldagem TIG com pulsação ultrassônica. 2013

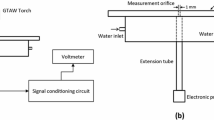

Cunha TV d, Bohórquez CEN (2014) Device for the arc pressure measurement and its application on the TIG welding process study. Revista Soldagem & Inspeção 19(2):152–158

Shirvan AJ et al (2018) Coupling boundary condition for high-intensity electric arc attached on a non-homogeneous refractory cathode. Comput Phys Commun 222:31–45

Lancaster JF (1984) The physics of welding. Phys Technol 15(2):73

Fan D, Ushio M, Matsuda F (1986) Numerical computation of arc pressure distribution (welding physics, process & instrument). Transactions of Joining and Welding Research Institute 15(1):1–5

Zhang G-J, Leng X-S, Lin WU (2006) Physics characteristic of coupling arc of twin-tungsten TIG welding. Trans Nonferrous Met Soc China 16(4):813–817

Mendez PF, Eagar TW (2003) Penetration and defect formation in high-current arc welding. Weld J 82(10):296

Yang M et al (2017) Arc force and shapes with high-frequency pulsed-arc welding. Sci Tech Weld Joining 22(7):580–586

Yang M, Yang Z, Qi B (2015) The effect of pulsed frequency on the plasma jet force with ultra high-frequency pulsed arc welding. Welding in the World 59(6):875–882

Yang M, Zheng H, Li L (2017) Arc shape characteristics with ultra-high-frequency pulsed arc welding. Appl Sci 7(1):45

Yang M et al (2017) Effect of arc behavior on Ti-6Al-4V welds during high frequency pulsed arc welding. J Mater Process Technol 243:9–15

Yang M, Yang Z, Qi B (2015) Effect of fluid in molten pool on the welds with Ti-6Al-4V during pulsed arc welding. Int J Adv Manuf Technol 81(5–8):1007–1016

Funding

The authors are grateful to the POSMEC - Graduate Program in Mechanical Engineering of the Federal University of Santa Catarina, the Welding Technology Laboratory (LTS) of the Federal University of Santa Catarina (UFSC - Technological Center of Joinville), the Brazilian National Council for Scientific and Technological Development (CNPq), and the company IMC Soldagem for supporting of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

da Cunha, T.V., Bohórquez, C.E.N. Effects of current pulsation at ultra-high frequency on physical aspects of the arc and its implications in the weld bead morphology in the GTAW process. Weld World 65, 251–261 (2021). https://doi.org/10.1007/s40194-020-01016-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01016-9