Abstract

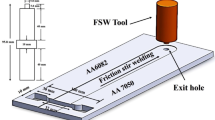

The effect of friction stir spot welding (FSSW) parameters on microstructure and mechanical properties of transformation-induced plasticity (TRIP) steel joints was investigated. The microstructure of the base metal and welding zone (stir zone, thermomechanically affected zone, and heat-affected zone) was examined using OM, SEM, EBSD, and XRD. The results of fractography of joints show that the microstructure and size of bonding ligament are the main parameters affected on the weld strength. The influence of FSSW parameters such as rotational speed, dwell time, and plunge depth on the strength of the TRIP steel joints was investigated using response surface methodology and considering bonding ligament of joints. The results of analysis of variance (ANOVA) show that the mathematical model was in good agreement with actual amounts of joints strength. Analysis of variance also determined that the plunge depth was a more effective parameter than other parameters. By optimization of the parameters, it was found that the maximum strength (9.42 kN) can be achieved by choosing of the rotational speed at 1218 rpm, dwell time at 1.65 s, and plunge depth at 0.19 mm.

Similar content being viewed by others

References

Shah U, Liu X (2019) Ultrasonic resistance welding of TRIP-780 steel. J Mater Process Technol 274:116287

Mostafapour A, Ebrahimpour A (2017) The effect of two-stage heat treatment temperatures on initial and FSSWed properties of TRIP steels. Int J Iron Steel Soc Iran 14(1):1–9

Reisner G, Werner E, Kerschbaummayr P, Papst I, Fischer F (1997) The modeling of retained austenite in low-alloyed TRIP steels. JOM 49(9):62–65

Vargas V, Mejía I, Baltazar-Hernández V, Maldonado C (2019) Effect of retained austenite and nonmetallic inclusions on the thermal/electrical properties and resistance spot welding nuggets of Si-containing TRIP steels. Int J Miner Metall Mater 26(1):52–63

Lomholt TC, Adachi Y, Peterson J, Steel R, Pantleon K, Somers MA (2011) Microstructure characterization of friction stir spot welded TRIP steel. Adv Mater Res 409:275–280

Mazzaferro C, Rosendo T, Tier M, Mazzaferro J, Dos Santos J, Strohaecker T (2015) Microstructural and mechanical observations of galvanized TRIP steel after friction stir spot welding. Mater Manuf Process 30(9):1090–1103

Thomas WM, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1991) Friction-stir butt welding. UK

Mishra RS, De PS, Kumar N (2014) Friction stir processing. Springer

Shen Z, Ding Y, Gerlich AP (2019) Advances in friction stir spot welding. Crit Rev Solid State Mater Sci 1–78

Lomholt TC, Pantleon K, MA. Somers (2011) Microstructure evolution during friction stir spot welding of TRIP steel, vol. 24. DTU Mekanik, Internet: https://orbit.dtu.dk/en/publications/microstructure-evolution-during-friction-stir-spot-welding-of-tri-2. Accessed 7 Oct 2020

Mostafapour A, Ebrahimpour A, Saeid T (2017) Numerical and experimental study on the effects of welding environment and input heat on properties of FSSWed TRIP steel. Int J Adv Manuf Technol 90(1–4):1131–1143

Mostafapour A, Ebrahimpour A, Saeid T (2017) Finite element investigation on the effect of FSSW parameters on the size of welding subdivided zones in TRIP steels. Int J Adv Manuf Technol 88(1–4):277–289

Ebrahimpour A, Mostafapour A, Samadian K (2018) Finite element and experimental investigation on the effects of temperature, strain and strain rate on microstructure and mechanical properties of FSSWed TRIP steel joints. Mater Res Express 6(1):016559

Mironov S, Sato Y, Yoneyama S, Kokawa H, Fujii H, Hirano S (2018) Microstructure and tensile behavior of friction-stir welded TRIP steel. Mater Sci Eng A 717:26–33

Tehrani-Moghadam H, Jafarian H, Salehi M, Eivani A (2018) Evolution of microstructure and mechanical properties of Fe-24Ni-0.3 C TRIP steel during friction stir processing. Mater Sci Eng A 718:335–344

Moghadam HT, Jafarian HR (2019) Effect of heat input on the microstructure of the friction stir weldedTRIP steel joints. ZANCO J Pure Appl Sci 31(s3):324–328

Lakshminarayanan AK, Annamalai VE, Elangovan K (2015) Identification of optimum friction stir spot welding process parameters controlling the properties of low carbon automotive steel joints. J Mater Res Tecnol 4(3):262–272

Archish R, Lakshminarayanan A, Annamalai V (2015) Optimum welding conditions for dissimilar spot friction joining of Aluminium-Interstitial free steel joints. Appl Mech Mater 787:396–400 Trans Tech Publ

Karthikeyan R, Balasubramanian V (2010) Predictions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. Int J Adv Manuf Technol 51(1–4):173–183

Manickam S, Balasubramanian V (2016) Optimizing the friction stir spot welding parameters to attain maximum strength in dissimilar joints of aluminum and carbon steel. Int J Mater Form Mach Process (IJMFMP) 3(2):64–76

Klobčar D, Tušek J, Smolej A, Simončič S (2015) Parametric study of FSSW of aluminium alloy 5754 using a pinless tool. Weld World 59(2):269–281

Sundaram M, Visvalingam B (2016) Optimizing the friction stir spot welding parameters to attain maximum strength in Al/Mg dissimilar joints. Journal of Welding and Joining 34(3):23–30

Khuri AI, Mukhopadhyay S (2010) Response surface methodology. Wiley Interdiscip Rev: Comput Stat 2(2):128–149

J. O. Andersson, T. Helander, L. Höglund, P. F. Shi, and B. Sundman (2002) Thermo-Calc. vol. 26. Calphad ed. Computational tools for materials science

Girault E (1998) Metallographic methods for revealing the multiphase microstructure of TRIP-assisted steels. Mater Charact 40(2):111–118

Mazzaferro C (2008) FSSW of TRIP 800; process, microstructure and properties. Ph.D, Universidade Federal Do Rio Grande Do Sul

Lomholt TC (2011) Microstructure evolution during friction stir spot welding of TRIP steel. Ph.D, Department of Mechanical Engineering, Technical University of Denmark, Denmark

(2010) E975-03, E975-03

Shena YF, Qiu LN, Sun X, Zuo L, Liawc PK, Raabe D (2015) Effects of retained austenite volume fraction, morphology, and carbon content on strength and ductility of nano structured TRIP-assisted steels. Mater Sci Eng A 636:551–564

Girault E, Mertens A, Jacques P, Houbaert Y, Verlinden B, Humbeeck JV (2001) Comparison of the effects of silicon and aluminium on the tensile behaviour of multiphase TRIP-assisted steels. ScriptaMaterialia 44(6):885–892

Sinha AK (2002) Physical metallurgy handbook. McGraw-Hill

Ion J, Easterling KE, Ashby M (1984) A second report on diagrams of microstructure and hardness for heat-affected zones in welds. Acta Metall 32(11):1949–1962

Zhu L-J, Di W, Zhao X-M (2007) Recrystallization modelling of hot deformed Si-Mn TRIP steel. J Iron Steel Res Int 14(2):61–65

Hidalgo J, Santofimia MJ (2016) Effect of prior austenite grain size refinement by thermal cycling on the microstructural features of as-quenched lath martensite. Metall Mater Trans A, 1–14

Bhadeshia H, Svensson L (1997) Mathematical modelling of weld phenomena III, Institute of Materials, vol 229, London

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Ebrahimpour, A., Mostafapour, A. & Nakhaei, M.R. Application of response surface methodology for weld strength prediction in FSSWed TRIP steel joints. Weld World 65, 183–198 (2021). https://doi.org/10.1007/s40194-020-01008-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01008-9