Abstract

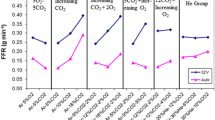

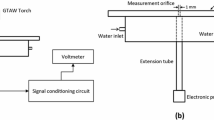

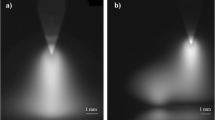

Shielding gas nozzle diameter variation and its impact on the anodic power distribution of low-current tungsten inert gas arcs were investigated, while maintaining either shielding gas flow rate or flow velocity constant. In addition, the effects of anode surface condition and flow behaviour type (laminar or turbulent) caused by the shielding gas nozzle applied were studied. It was found that arcs of 50 amperes (A) welding current were highly unstable deploying the conditions used, while increasing the arc electrical current to 100 A led to improved arc stability. As found in previous investigations, non-Gaussian distribution profiles occurred at 50 A, even with improved shielding. The power density maxima were found shifted away from the arc axis.

Similar content being viewed by others

References

Fihey J, Simoneau R (1982) Weld penetration variation in GTA welding of some 304 L stainless steels. in Proc. Welding Technology for Energy Applications, Gatlinburg

Norrish J (2006) Advanced welding processes. Woodhead Publishing Ltd., Cambridge

Schellhase M, (1985) Der Schweißlichtbogen - ein technologisches Werkzeug. Fachbuchreihe Schweisstechnik. Düsseldorf (in German): Deutscher Verlag für Schweisstechnik. 236

Lancaster, J.F. (1984) The physics of welding. , Oxford: Pergamon, p: 170

Vilarinho LO, Scotti A (2004) Proposal for a modified Fowler-Milne method to determine the temperature profile in TIG welding at low currents. J Braz Soc Mech Sci Eng 26(1):34–39

Weglowski M (2005) Determination of GTA and GMA welding arc temperatures. Weld Int 19(3):186–192

Haddad G, Farmer A (1984) Temperature determinations in a free-burning arc. I. Experimental techniques and results in argon. J Phys D Appl Phys 17(6):1189

Farmer A, Haddad G, Cram L (1986, 1723) Temperature determinations in a free-burning arc. III. Measurements with molten anodes. J Phys D Appl Phys 19(9)

Degout D, Catherinot A (1986) Spectroscopic analysis of the plasma created by a double-flux tungsten inert gas (TIG) arc plasma torch. J Phys D Appl Phys 19(5):811

Tanaka M, Ushio M (1999) Plasma state in free-burning argon arc and its effect on anode heat transfer. J Phys D Appl Phys 32(10):1153

Tanaka M, Ushio M (1999) Observations of the anode boundary layer in free-burning argon arcs. J Phys D Appl Phys 32(8):906

Terasaki H, Tanaka M, Ushio M (2002) Effects of metal vapor on electron temperature in helium gas tungsten arcs. Metall Mater Trans A 33(4):1183–1188

Lu M, Kou S (1988) Power and current distributions in gas tungsten arcs. Weld. J.(Miami);(United States) 67(2):29s–34s

Tsai M, Kou S (1990) Heat transfer and fluid flow in welding arcs produced by sharpened and flat electrodes. Int J Heat Mass Transf 33(10):2089–2098

Cram L, Poladian L, Roumeliotis G (1988) Departures from equilibrium in a free-burning argon arc. J Phys D Appl Phys 21(3):418

Wu C, Ushio M, Tanaka M (1997) Analysis of the TIG welding arc behavior. Comput Mater Sci 7(3):308–314

Biswas K (1994) A numerical prediction of the temperature distribution in the thermionic cathode of a welding arc. J Mater Process Technol 40(1):219–237

Fan H, Tsai H-L, Na S (2001) Heat transfer and fluid flow in a partially or fully penetrated weld pool in gas tungsten arc welding. Int J Heat Mass Transf 44(2):417–428

Wu C, Gao J (2002) Analysis of the heat flux distribution at the anode of a TIG welding arc. Comput Mater Sci 24(3):323–327

Ramírez MA, Trapaga G, McKelliget J (2004) A comparison between different numerical formulations for welding arc representations. J Mater Process Technol 155:1634–1640

Lu F et al (2004) Modeling and finite element analysis on GTAW arc and weld pool. Comput Mater Sci 29(3):371–378

Lu F et al (2006) Numerical simulation on interaction between TIG welding arc and weld pool. Comput Mater Sci 35(4):458–465

Hiraoka K, Okada A, Inagaki M (1985) Effect of electrode geometry on maximum arc pressure in gas tungsten arc welding. Quarterly Journal of the Japan Welding Society 3(2):246–252

Kobayashi K et al (2004) Practical application of high efficiency twin-arc TIG welding method (SEDAR-TIG) for PCLNG storage tank. Welding in the World 48(7–8):35–39

Oh DS, Kim YS, Cho SM (2005) Derivation of current density distribution by arc pressure measurement in GTA welding. Sci Technol Weld Join 10(4):442–446

Ham HS, Oh DS, Cho SM (2012) Measurement of arc pressure and shield gas pressure effect on surface of molten pool in TIG welding. Sci Technol Weld Join 17(7):594–600

Egerland S, Colegrove P, Williams S (2016) Investigation of low current gas tungsten arc welding using split anode calorimetry. Sci Technol Weld Join:1–8

Egerland S, Colegrove P, Williams S (2018) Arc instabilities during split anode calorimetry with the TIG welding process. Welding in the World 62(4):831–845

Nestor OH (1959) An experimental determination of current density and heat transfer intensity distributions at the anode of high current, inert gas arcs, in School of Arts and Sciences, vol 65–85. University of Buffalo, Buffalo

Nestor O, Olsen H (1960) Numerical methods for reducing line and surface probe data. SIAM Rev 2(3):200–207

Nestor OH (1962) Heat intensity and current density distributions at the anode of high current, inert gas arcs. J Appl Phys 33(5):1638–1648

Tsai N (1983) Heat distribution and weld bead geometry in arc welding, in Dept. of Materials Science and Engineering. , Massachusetts Institute of Technology: Massachusetts, p 282

Ushio M, Tanaka M, Lowke JJ (2004) Anode melting from free-burning argon arcs. Plasma Science, IEEE Transactions on 32(1):108–117

Tanaka M, Lowke JJ (2007) Predictions of weld pool profiles using plasma physics. J Phys D Appl Phys 40(1):R1–R23

Tanaka M et al (2006) Anode heat transfer in TIG welding and its effect on the cross-sectional area of weld penetration. Weld Int 20(4):268–274

Füssel U et al (2007) Experimentelle Möglichkeiten der WSG-Lichtbogenanalyse. Schweißen und Schneiden 59(7):396–403 (in German)

O’Brian A (ed) (2004) N.N., AWS welding handbook - welding processes–part 1, vol 2. American Welding Society, Miami

Ramsey G et al (2012) A computational fluid dynamic analysis of the effect of side draughts and nozzle diameter on shielding gas coverage during gas metal arc welding. J Mater Process Technol 212(8):1694–1699

Campbell S et al (2013) A computational fluid dynamic analysis of the effect of weld nozzle geometry changes on shielding gas coverage during gas metal arc welding. J Manuf Sci Eng 135(5):051016

Dreher M et al (2009) Numerical simulation of the shielding gas flow with GMA welding and options of validation by diagnostics. Mater Sci Technol 2:39–49

Siewert E et al (2014) Visualization of gas flows in welding arcs by the Schlieren measuring technique. Weld J 93(1):1–5

N.N. Isobaric properties for water - isobaric data for P = 1.0000 bar. 2018 17.11.2018; Available from: https://tinyurl.com/yb89rrav

N.N. Isobaric properties for water. 2018 17.11.2018; Available from: https://tinyurl.com/yd4p2man

Norrish J (2018) Shielding gas nozzle design and gas flow conditions (personal discussion). Unpublished

N.N. KASTILO aramide fibres (2018) cited 2018 13.10.; Available from: http://www.kastilo.com/en/kastilo-technische-gewebe-gmbh-aramidfasern-kevlar-nomex-twaron

Munson BR, Young DF, Okiishi TH (1994) Fundamentals of fluid mechanics, vol 893, 2nd edn. John Wiley & Sons, Inc., New York

Johnson D, Orakwe P, Weckman E (2006) Experimental examination of welding nozzle jet flow at cold flow conditions. Sci Technol Weld Join 11(6):681–687

Brahinsky HS, Neel CA, (1969) Tables of equilibrium thermodynamic properties of argon - constant pressure. Arnold Engineering Development Center Arnold AFB TN

N.N. DiracDelta.co.uk - science and engineering encyclopedia. 2018 [cited 2018 24. June]

Schoeck PA (1963) An investigation of the anode energy balance of high intensity arcs in argon, in Modern developments in heat transfer. Academic Press New York, New York, pp 353–400

Tsai N, Eagar T (1985) Distribution of the heat and current fluxes in gas tungsten arcs. Metall Trans B 16(4):841–846

Heberlein J, Pfender E (1977) Investigation of the anode boundary layer of an atmospheric pressure argon arc. Plasma Science, IEEE Transactions on 5(3):171–180

Vilarinho L, Scotti A (2006) Caracterização de arcos TIG via análise numérica. Soldagem & Inspeção 11:200–207 (in Portuguese)

Marchandise H (1970) Plasmatechnologie - Grundlagen und Anwendung. DVS-Berichte Band 8. Deutscher Verlag für Schweisstechnik, Düsseldorf (in German)

Poloskov S, Erofeev V, Logvin R (2006) Modelling the distribution of the heat flow and arc pressure in orbital TIG welding. Weld Int 20(1):53–58

Acknowledgments

The authors are indebted to FRONIUS International GmbH Wels, Austria, for the permit to use welding equipment and facilities, as well as for the provision of materials and consumables. Special gratitude is devoted to Mr. Andreas Leonhartsberger for granting unselfish assistance in producing the shielding gas chamber and in conducting the shielding gas flow visualisation experiments. Finally, special thanks are given to the peer reviewers for their careful reading and for raising valuable comments and questions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Egerland, S., Colegrove, P. & Williams, S. Influence of shielding gas nozzle design on power density distribution in low-current TIG welding arcs. Weld World 64, 831–845 (2020). https://doi.org/10.1007/s40194-020-00876-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00876-5