Abstract

One of the methods to achieve local change in material properties when producing high strength parts with tailored mechanical properties is variating temperature histories in the furnace prior to hot stamping. This causes changes in surface layer development of coated steels and thus differences in contact resistances, which determine heat development during the resistance welding process. To get a deeper understanding of the influences, surface layers have on the welding process, parts with temperature histories, typical for industrially manufactured partially hot-stamped parts with aluminum-silicon and zinc coatings were investigated. Static contact resistance was determined; measurements of dynamic resistances in welding process were conducted. Welding current ranges were determined for different heat-treated conditions. No correlation between static contact resistance and welding current range was found; however for Zn coating, the welding current range was moved towards lower welding currents and shrinked for the measured total static contact resistance of about 4000 μΩ. For aluminum-silicon coating, no dependence between welding current range and static contact resistance was evident. For Al-Si-coated steel, a novel criterion, based on the fraction of the resistive phases in the surface layer, determined by metallographic investigations was developed, allowing to determine material joinability.

Similar content being viewed by others

References

Effenberg G, Landolt H, Börnstein R, Martienssen W, Madelung O (2005) Numerical data and functional relationships in science and technology. New series. Springer, Berlin

Drillet P, Spehner D, Kefferstein R Coated steel strips - European Patent Office - EP 2086755 B1. Abrufdatum 23.11.2018

Grigorieva R, Drillet P, Mataigne JM, Redjaïmia A (2011) Phase transformations in the Al-Si coating during the austenitization step. Solid State Phenom 172-174:784–790

Jenner F, Walter ME, Mohan Iyengar R, Hughes R (2010) Evolution of phases, microstructure, and surface roughness during heat treatment of aluminized low carbon steel. Metall Mater Trans A 41(6):1554–1563

Windmann M, Röttger A, Theisen W (2014) Formation of intermetallic phases in Al-coated hot-stamped 22MnB5 sheets in terms of coating thickness and Si content. Surf Coat Technol 246:17–25

Janik V, Lan Y, Beentjes P, Norman D, Hensen G, Sridhar S (2016) Zn diffusion and α-Fe(Zn) layer growth during annealing of Zn-coated B steel. Metall Mater Trans A 47(1):400–411

Ighodaro OL-R, Biro E, Zhou YN (2017) Study and applications of dynamic resistance profiles during resistance spot welding of coated hot-stamping steels. Metall Mater Trans A 48(2):745–758

Laurenz R, Ohse P (2012) Einfluss der Ofenverweilzeit von metallisch überzogenem Warmumformstahl auf die Eignung zum Widerstandspunkt-, Buckel- und Lichtbogenbolzenschweißen. Schweißen und Schneiden 64(10):654–661

Kuhlmann M, Mitzschke, Niels, Wohner, Maximilian, Jüttner S (2017) Einfluss von Prozessbedingungen beim Formhärten auf die Verbindungseigenschaften gefügter Bauteile. In: Merklein M, Warmblechumformung EW (eds) 12. Erlanger Workshop Warmblechumformung. Tagungsband zum 12. Erlanger Workshop Warmblechumformung: Erlangen, den 23. November 2017. Bamberg

Faderl J, Kolnberger S, Kurz T, Luckaender G, Manzenreiter T, Rosner M (2009) phs-ultraform®—continuous galvanizing meets press-hardening. In: Oldenburg M, Steinhoff K (eds) Hot sheet metal forming of high-performance steel. 2nd international conference; CHS2 , June 15–17, 2009, Luleå, Sweden ; proceedings ; CHS2-series No. 2. Auerbach

Marc J van Genderen, Wico C Verloop, Jenny Loiseaux, Guido C Hensen (2011) Zinc-coated boron steel, ZnX®: direct hot forming for automotive applications. In: Oldenburg M, Steinhoff K (eds) Hot sheet metal forming of high-performance steel - CHS2. 3rd international conference; June 13–17, 2011, Kassel, Germany; proceedings; CHS2-series No. 3. Auerbach

Horn A, Merklein M (2018) Fertigung funktionsoptimierter Bauteile beim Presshärten. In: Merklein M, Hell H, Horn A (eds) 13. Erlanger Workshop Warmblechumformung. Tagungsband zum 13. Erlanger Workshop Warmblechumformung. Erlangen

Lehmann H, Etzold U (2018) Wärmebehandlungsanlage zum Thermischen Printen für daspartielle Vergüten beim Presshärten. In: Merklein M, Hell H, Horn A (eds) 13. Erlanger Workshop Warmblechumformung. Tagungsband zum 13. Erlanger Workshop Warmblechumformung. Erlangen

Sherepenko O, Schreiber V, Schischin I, Luo Y, Wernlein P, Jüttner S (2019) Einfluss des Oberflächen- und Werkstoffzustandes auf die Punktschweißeignung partiell gehärteter Bauteile mit Al-Si Beschichtungen. In: DVS Media GmbH (ed) 24. DVS-Sondertagung Widerstandsschweißen. Treffpunkt Widerstandsschweißen

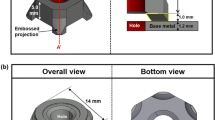

Deutscher Verband für Schweißen und verwandte Verfahren e.V.: DVS 2929–1. Messung des Übergangswiderstands, Grundlagen, Messmethoden und -einrichtungen (2014)

Deutscher Verband für Schweißen und verwandte Verfahren e.V.: DVS 2935–3. Widerstandspunktschweißen von Feinblechen aus niedrig legierten Stählen, Presshärtende Stähle (2019)

Deutsches Institut für Normung e.V.: Prüf- und Dokumentationsrichtlinie für die Fügeeignung von Feinblechen aus Stahl - Teil 2: Widerstandspunktschweißen (2011) 1220-2. Berlin

Fan DW, de Cooman BC (2012) State-of-the-knowledge on coating systems for hot stamped parts. Steel Res Int 83(5):412–433

Horie T, Niho T, Hayashi N, Ishihara D (2019) Cycles of triply coupled mechanical contact, current, and thermal conduction phenomena during resistance spot welding. Weld World 6 3:126

Windmann M, Röttger A, Theisen W (2013) Phase formation at the interface between a boron alloyed steel substrate and an Al-rich coating. Surf Coat Technol 226:130–139

Lilly AC, Deevi SC, Gibbs ZP (1998) Electrical properties of iron aluminides. Mater Sci Eng A 258(1–2):42–49

Pazourek A, Pfeiler W, Šíma V (2010) Dependence of electrical resistivity of Fe–Al alloys on composition. Intermetallics 18(7):1303–1305

Wink H-J, Krätschmer M (2012) Charakterisierung und Modellierung des Bruchverhaltens von Punktschweißverbindungen in pressgehärteten Stählen. Teil II - Simulation des Schweißens. Ulm

Brandes EA, Brook GB, Smithells CJ (1998) In: Brandes EA, Brook GB (eds) Smithells metals reference book, 7th edn. Butterworth-Heinemann, Oxford, Boston

Meyer R (2012) Erhöhung der Prozesssicherheit durch Beherrschung der Bauteilabweichung beim Fügen im Karosseriebau. TUDpress, Dresden

Saha DC, Ji CW, Park YD (2015) Coating behaviour and nugget formation during resistance welding of hot forming steels. Sci Technol Weld Join 20(8):708–720

Acknowledgments

The authors would like to thank AiF for funding the IGF-Project IGF-Nr.:18.939B (DVS-Nr.: 04.060) of the Research Association on Welding and Allied Processes of the DVS, which was part of the program to support cooperative industrial research (Industrielle Gemeinschaftsförderung (IGF)) by the Federal Ministry for Economic Affairs and Energy, following a decision of the German Bundestag. Equal thanks go to all companies, colleagues, and students who contributed their support, knowledge, and effort to the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Sherepenko, O., Schreiber, V., Schischin, I. et al. Influence of surface layers on resistance spot joinability of partially hardened steel 22MnB5 with aluminum-silicon and zinc coatings. Weld World 64, 755–771 (2020). https://doi.org/10.1007/s40194-020-00864-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00864-9