Abstract

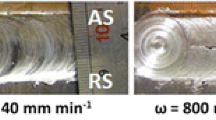

A butt joint configuration of AA6061–pure Ti was welded using friction stir welding (FSW) with an assisted cooling and heating conditions, aiming to attain a flawless joint. Cooling-assisted friction stir welding (CFSW) was carried out with a different cooling medium such as CO2, compressed air and water at controlled flow rate. However, heating-assisted friction stir welding (HFSW) was performed with heating source of GTAW torch just before FSW tool at different current density. Prepared specimens were subjected to optical microscopy (OM), scanning electron microscopy (SEM) and electrodischarge spectroscopy (EDS) for microstructural characterizations. The tensile strength and microhardness were significantly affected by various cooling and heating conditions, attributing to the distinct proportion of the intermetallic compounds (IMCs) evident in the microstructure. The samples prepared with cooling conditions exhibited superior joint properties as compared with the normal and heating conditions.

Graphical abstract

Similar content being viewed by others

References

Kimapong K, Watanabe T (2004) Friction stir welding of aluminum alloy to steel. Weld J 83(10):277

Eslami N, Harms A, Henke B, Fricke A, Böhm S (2019) Electrical and mechanical properties of friction stir welded Al-Cu butt joints. Welding in the World 63(3):903–911. https://doi.org/10.1007/s40194-019-00719-y

Regensburg A, Petzoldt F, Benss T, Bergmann JP (2019) Liquid interlayer formation during friction stir spot welding of aluminum/copper. Welding in the World 63(1):117–125. https://doi.org/10.1007/s40194-018-0620-8

Yang X, Li W, Xu Y, Wen Q, Feng W, Wang Y (2019) Effect of welding speed on microstructures and mechanical properties of Al/Cu bimetal composite tubes by a novel friction-based welding process. Welding in the World 63(1):127–136. https://doi.org/10.1007/s40194-018-0652-0

Lukács J, Meilinger Á, Pósalaky D (2018) High cycle fatigue and fatigue crack propagation design curves for 5754-H22 and 6082-T6 aluminium alloys and their friction stir welded joints. Welding in the World 62(4):737–749. https://doi.org/10.1007/s40194-018-0599-1

Skoda P, Dupak J, Michalicka P Creation of heterogeneous weld joints of titanium-and aluminium-based materials by electron beam welding. In: Proc. Int. Welding Conf., Japan Slovak Welding Symp., Tatranske Matliare, Tatranska Lomnica, 1996. pp 157–160

Kreimeyer M, Wagner F, Vollertsen F (2005) Laser processing of aluminum–titanium-tailored blanks. Opt Lasers Eng 43(9):1021–1035

Osokin A (1976) Technological characteristics of fusion-welding of aluminum-alloys to titanium-alloys. Weld Prod 23(2):18–20

Hosseini SRE, Feng K, Nie P, Zhang K, Huang J, Chen Y, Shu D, Li Z, Guo B, Xue S (2018) Fracture surface characterization of laser welding processed Ti alloy to stainless steel joints. Welding in the World 62(5):947–960. https://doi.org/10.1007/s40194-018-0586-6

Surendar A, Lucas A, Abbas M, Rahim R, Salmani M (2019) Transient liquid phase bonding of stainless steel 316 L to Ti-6Al-4 V using Cu/Ni multi-interlayer: microstructure, mechanical properties, and fractography. Welding in the World 63(4):1025–1032. https://doi.org/10.1007/s40194-019-00742-z

Karfoul MK, Tatlock GJ (2019) Interfacial processes during diffusion welding of titanium alloy/aluminium couples under ambient atmosphere. Welding in the World 63(3):841–849. https://doi.org/10.1007/s40194-019-00711-6

Li B, Zhang Z, Shen Y, Hu W, Luo L (2014) Dissimilar friction stir welding of Ti–6Al–4V alloy and aluminum alloy employing a modified butt joint configuration: influences of process variables on the weld interfaces and tensile properties. Mater Des 53:838–848

Bang H, Bang H, Song H, Joo S (2013) Joint properties of dissimilar Al6061-T6 aluminum alloy/Ti–6% Al–4% V titanium alloy by gas tungsten arc welding assisted hybrid friction stir welding. Mater Des 51:544–551

Wei Y, Li J, Xiong J, Huang F, Zhang F, Raza SH (2012) Joining aluminum to titanium alloy by friction stir lap welding with cutting pin. Mater Charact 71:1–5

Dressler U, Biallas G, Mercado UA (2009) Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater Sci Eng A 526(1–2):113–117

Bang K-S, Lee K-J, Bang H-S, Bang H-S (2011) Interfacial microstructure and mechanical properties of dissimilar friction stir welds between 6061-T6 aluminum and Ti-6% Al-4% V alloys. Mater Trans 52(5):974–978

Vander Voort GF, Lampman SR, Sanders BR, Anton GJ, Polakowski C, Kinson J, Muldoon K, Henry SD, Scott WW Jr (2004) ASM handbook. Metallography and microstructures 9:44073–40002

Schneider J, Nunes A (2004) Characterization of plastic flow and resulting microtextures in a friction stir weld. Metall Mater Trans B Process Metall Mater Process Sci 35(4):777–783

Malik V, Kailas SV (2018) Plasticine modeling of material mixing in friction stir welding. J Mater Process Technol 258:80–88

Joshi GR, Badheka VJ (2017) Microstructures and properties of copper to stainless steel joints by hybrid FSW. Metallography, Microstructure, and Analysis 6(6):470–480

Mehta KP, Badheka VJ (2017) Hybrid approaches of assisted heating and cooling for friction stir welding of copper to aluminum joints. J Mater Process Technol 239:336–345

Rana H, Badheka V (2018) Influence of friction stir processing conditions on the manufacturing of Al-Mg-Zn-Cu alloy/boron carbide surface composite. J Mater Process Technol 255:795–807

Rana H, Badheka V (2017) Elucidation of the role of rotation speed and stirring direction on AA 7075-B4C surface composites formulated by friction stir processing Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (0):1-18

Rana H, Badheka V, Kumar A, Satyaprasad A (2017) Strategical parametric investigation on manufacturing of Al-Mg-Zn-Cu alloy surface composites using FSP. Mater Manuf Process:1–12

Patel V, Li WY, Vairis A, Badheka VJ (2019) Recent development in friction stir processing as a solid-state grain refinement technique: microstructural evolution and property enhancement. Crit Rev Solid State Mater Sci 44(5):378–426. https://doi.org/10.1080/10408436.2018.1490251

Patel V, Li WY, Xu Y (2019) Stationary shoulder tool in friction stir processing: a novel low heat input tooling system for magnesium alloy. Mater Manuf Process 34(2):177–182. https://doi.org/10.1080/10426914.2018.1544716

Patel V, Li WY, Wang G, Wang F, Vairis A, Niu P (2019) Friction stir welding of dissimilar aluminum alloy combinations: state-of-the-art. Metals 9(3):270

Patel V, Badheka V, Kumar A (2016) Influence of friction stir processed parameters on superplasticity of Al-Zn-Mg-Cu alloy. Mater Manuf Process 31(12):1573–1582. https://doi.org/10.1080/10426914.2015.1103868

Ma Z, Mishra RS, Mahoney MW (2002) Superplastic deformation behaviour of friction stir processed 7075Al alloy. Acta Mater 50(17):4419–4430

Patel VV, Badheka V, Kumar A (2017) Effect of polygonal pin profiles on friction stir processed superplasticity of AA7075 alloy. J Mater Process Technol 240:68–76

Tan C, Jiang Z, Li L, Chen Y, Chen X (2013) Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater Des 51:466–473

Mironov S, Sato Y, Kokawa H (2019) Influence of welding temperature on material flow during friction stir welding of AZ31 magnesium alloy. Metallurgical and Materials Transactions A:1–9

Huang Y, Wang Y, Wan L, Liu H, Shen J, dos Santos JF, Zhou L, Feng J (2016) Material-flow behavior during friction-stir welding of 6082-T6 aluminum alloy. Int J Adv Manuf Technol 87(1–4):1115–1123

Aonuma M, Nakata K (2011) Dissimilar metal joining of 2024 and 7075 aluminium alloys to titanium alloys by friction stir welding. Mater Trans 52(5):948–952

Pretorius R, Vredenberg A, Saris F, De Reus R (1991) Prediction of phase formation sequence and phase stability in binary metal-aluminum thin-film systems using the effective heat of formation rule. J Appl Phys 70(7):3636–3646

Avettand-Fenoel M, Taillard R, Ji G, Goran D (2012) Multiscale study of interfacial intermetallic compounds in a dissimilar Al 6082-T6/Cu friction-stir weld. Metall Mater Trans A 43(12):4655–4666

Wilden J, Bergmann JP (2004) Manufacturing of titanium/aluminium and titanium/steel joints by means of diffusion welding. Weld Cut 56(5):285–290

Wei Y, Aiping W, Guisheng Z, Jialie R (2008) Formation process of the bonding joint in Ti/Al diffusion bonding. Mater Sci Eng A 480(1–2):456–463

Kim Y-C, Fuji A (2002) Factors dominating joint characteristics in Ti–Al friction welds. Sci Technol Weld Join 7(3):149–154

Chen Y, Nakata K (2009) Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater Des 30(3):469–474

Y-h CHEN, Quan N, L-m KE (2012) Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys. Trans Nonferrous Metals Soc China 22(2):299–304

Ramesh C, Ahmed RN, Mujeebu M, Abdullah M (2009) Development and performance analysis of novel cast copper–SiC–Gr hybrid composites. Mater Des 30(6):1957–1965

Acknowledgements

We acknowledge ISRO (in collaboration with SAC), for providing machine setup under RESPOND (ISRO/RES/4/567/09-10) program.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Patel, P., Rana, H., Badheka, V. et al. Effect of active heating and cooling on microstructure and mechanical properties of friction stir–welded dissimilar aluminium alloy and titanium butt joints. Weld World 64, 365–378 (2020). https://doi.org/10.1007/s40194-019-00838-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00838-6