Abstract

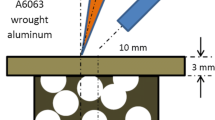

Laser welding of open-cell aluminum foam and solid shell was performed with the objective of fabricating promising hybrid metallic materials. In this study, a feasibility of laser welding of a solid A6063 aluminum sheet to an open-cell AC2A aluminum foam was investigated. The effects of various laser-welding parameters such as laser power, welding speed, and defocused distance in addition to the pore size of aluminum foam were evaluated in terms of the shear strengths of the welded joints between the aluminum solid sheet and porous plate. Increases in weld joint width (w) and penetration depth (d) were effective to an increase in the tensile shear strength of solid-porous material joint.

Similar content being viewed by others

References

Ashby MF (2000) Metal foam: a design guide. Butterworth-Heinemann, Oxford, pp 195–199

Ascari A, Campana G (2013) Application of laser in joining aluminum foam hybrid materials. Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference, USA:1–8

Bernard T, Burzer J, Bergmann HW (2001) Mechanical properties of structures of semifinished products joined to aluminum foam. J Mater Process Technol 115:20–24

Davis GJ, Zhen S (1983) Metallic foams: their production, properties and applications. Mater Sci 18:1899–1911

Banhart J (2000) Manufacturing routes for metallic foams, Overview Solidification Science. JOM 52:22–27

Nakajima H (2007) Fabrication, properties and application of porous metals with directional pores. Prog Mater Sci 52:1091–1173

Biffi CA, Colombo D, Tuissi A (2014) Laser beam welding of CuZn open-cell foams. Opt Lasers Eng 62:112–118

Eriksson I, Powell J, Kaplan AFH (2013) Melt behavior on the keyhole front during high speed laser welding. Opt Lasers Eng 51:735–740

Huang L, Hua X, Wu D, Li F (2017) Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J Mater Process Technol 252:421–431

Arata Y (1986) Plasma, electron and laser beam technology. American Society for Metals, Metals Park

Kim JS, Watanabe T, Yoshida Y (1995) Effect of the beam-defocusing characteristics on porosity formation in laser welding. J Mater Sci Lett 14(22):1624–1626

Burzer J, Bernard T, Bergmann HW (1998) Joining of aluminium structures with aluminium foams. Proceeding of porous and cellular materials for structural applications symposium, San Francisco, USA:158–164

Andrews E, Sanders W, Gibson LJ (1999) Compressive and tensile behaviour of aluminum foams. Mater Sci Eng A 270:113–124

Nowacki J, Moraniec K (2015) Welding of metallic AlSi foams and AlSi–SiC composite foams. ACME 15:940–950

Acknowledgements

The authors would like to thank Dr. Sompong Srimanosaowapak from National Metal and Materials Technology Center (MTEC) for the production of open-cell aluminum and Mr. Qinglong Pan, a graduate student for operating disk laser welding system at Joining and Welding Research Institute (JWRI) of Osaka University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Phongphisutthinan, C., Wattanapornphan, P., Suga, T. et al. Laser welding for joining of open-cell aluminum foam to solid shell. Weld World 63, 825–839 (2019). https://doi.org/10.1007/s40194-019-00709-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00709-0