Abstract

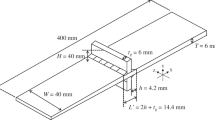

Friction self-piercing riveting (F-SPR) process has been proposed to achieve crack-free joining of low-ductility materials by combining SPR process with the concept of friction stir processing. The inhibition of cracking in an F-SPR joint is related to the in-process temperature as well as plastic deformation of materials, which are controlled by the process parameters, i.e., spindle speed and feed rate. However, the relationship between F-SPR process parameters and the temperature characteristics within the joint has not been established. In the current study, a coupled thermal-mechanical model based on solid mechanics was setup to study the F-SPR process of aluminum alloy and magnesium alloy. Temperature and strain rate-dependent material models and preset crack surface method were integrated in the model and geometry comparisons were conducted for model validation. Based on this model, the evolutions of temperature and plastic deformation in the rivet and the sheets of an F-SPR joint were obtained to reveal the formation mechanism of the joint. The temperature distribution and evolution of the sheet materials were correlated with F-SPR process parameters, and a critical spinning speed of 2000 rpm at a feed rate of 1.35 mm/s was determined capable of inhibiting cracking in the magnesium sheet.

Similar content being viewed by others

References

Figner G, Vallant R, Weinberger T, Enzinger N, Schröttner H, Paśič H (2013) Friction stir spot welds between aluminium and steel automotive sheets: influence of welding parameters on mechanical properties and microstructure. Welding in the World 53(1–2):R13–R23

Liu L, Ren D, Liu F (2014) A review of dissimilar welding techniques for magnesium alloys to aluminum alloys. Materials (Basel) 7(5):3735–3757

Sigler DR, Carlson BE, Janiak P (2013) Improving aluminum resistance spot welding in automotive structures. Weld J 92(6):64–72

Qi X-d, Liu L-m (2012) Fusion welding of Fe-added lap joints between AZ31B magnesium alloy and 6061 aluminum alloy by hybrid laser–tungsten inert gas welding technique. Mater Des 33:436–443

Hayat F (2011) The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials. Mater Des 32(4):2476–2484

Sun M, Behravesh SB, Wu L, Zhou Y, Jahed H (2017) Fatigue behaviour of dissimilar Al 5052 and Mg AZ31 resistance spot welds with Sn-coated steel interlayer. Fatigue & Fracture of Engineering Materials & Structures 40(7):1048–1058

He X, Zhao L, Deng C, Xing B, Fengshou G, Ball A (2015) Self-piercing riveting of similar and dissimilar metal sheets of aluminum alloy and copper alloy. Materials & Design (1980–2015) 65:923–933

Mori K, Abe Y, Kato T (2014) Self-pierce riveting of multiple steel and aluminium alloy sheets. J Mater Process Technol 214(10):2002–2008

Ma YW, Lou M, Li YB, Lin ZQ (2018) Effect of rivet and die on self-piercing rivetability of AA6061-T6 and mild steel CR4 of different gauges. J Mater Process Technol 251:282–294

Luo AA, Lee TM, Carter JT (2011) Self-pierce riveting of magnesium to aluminum alloys. SAE International Journal of Materials and Manufacturing 4(1):158–165

Durandet Y, Deam R, Beer A, Song W, Blacket S (2010) Laser assisted self-pierce riveting of AZ31 magnesium alloy strips. Mater Des 31(SUPPL. 1):S13–S16

Wang JW, Liu ZX, Shang Y, Liu AL, Wang MX, Sun RN, Wang P-C (2011) Self-piercing riveting of wrought magnesium AZ31 sheets. J Manuf Sci Eng 133(3):031009

Jäger A, Lukáč P, Gärtnerová V, Bohlen J, Kainer KU (2004) Tensile properties of hot rolled AZ31 Mg alloy sheets at elevated temperatures. J Alloys Compd 378(1–2):184–187

Li YB, Wei ZY, Wang ZZ, Li YT (2013) Friction self-piercing riveting of aluminum alloy AA6061-T6 to magnesium alloy AZ31B. J Manuf Sci Eng 135(6):061007

Ma Y, Lou M, Yang Z, Li Y (2015) Effect of rivet hardness and geometrical features on friction self-piercing riveted joint quality. J Manuf Sci Eng 137(5):054501

Liu X, Lim YC, Li Y, Tang W, Ma Y, Feng Z, Ni J (2016) Effects of process parameters on friction self-piercing riveting of dissimilar materials. J Mater Process Technol 237:19–30

Ma YW, Li YB, Wei H, Lou M, Lin ZQ (2016) Modeling of friction self-piercing riveting of aluminum to magnesium. J Manuf Sci Eng 138(6):061007

Min J, Li J, Carlson BE, Li Y, Quinn JF, Lin J, Wang W (2015) Friction stir blind riveting for joining dissimilar cast Mg AM60 and Al alloy sheets. J Manuf Sci Eng 137(5):051022

Han G, Wang M, Liu Z, Wang P-C (2013) A new joining process for magnesium alloys: rotation friction drilling riveting. J Manuf Sci Eng 135(3):031012

Zhang XX, Xiao BL, Ma ZY (2011) A transient thermal model for friction stir weld. Part I: the model. Metall Mater Trans A 42(10):3218–3228

Nandan R, Roy GG, Lienert TJ, Debroy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. in Proc. 7th Int. Symp. on Ballistics

Al-Badour F, Merah N, Shuaib A, Bazoune A (2013) Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J Mater Process Technol 213(8):1433–1439

Ulacia I, Salisbury CP, Hurtado I, Worswick MJ (2011) Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures. J Mater Process Technol 211(5):830–839

Zhang C, Ma G, Nie J, Ye J (2015) Numerical simulation of AZ31B magnesium alloy in DE-GMAW welding process. Int J Adv Manuf Technol 78(5–8):1259–1264

Gao Z, Niu JT, Krumphals F, Enzinger N, Mitsche S, Sommitsch C (2013) FE modelling of microstructure evolution during friction stir spot welding in AA6082-T6. Welding in the World 57(6):895–902

Livermore Software Technology Corporation (2016) LS-DYNA keyword user’s manual, volume 1, version r7598. p. 635

Liu X, Lan S, Ni J (2015) Thermal mechanical modeling of the plunge stage during friction-stir welding of dissimilar Al 6061 to TRIP 780 steel. J Manuf Sci Eng 137(5):051017

Khandkar MZH, Khan JA, Reynolds AP (2013) Prediction of temperature distribution and thermal history during friction stir welding: input torque based model. Sci Technol Weld Join 8(3):165–174

Funding

The authors would like to thank the financial support of the National Natural Science Foundation of China (Grant Nos. U1564204 and U1764251) and the National Key Research and Development Program of China (Grant No. 2016YFB0101606-08).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Ma, Y., Lou, M., Li, Y. et al. Modeling and experimental validation of friction self-piercing riveted aluminum alloy to magnesium alloy. Weld World 62, 1195–1206 (2018). https://doi.org/10.1007/s40194-018-0614-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0614-6