Abstract

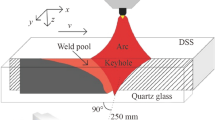

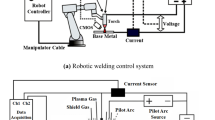

The controlled-pulse strategy is proposed to improve the keyholing stability and dynamics in plasma arc welding (PAW). A cost-effective vision system is developed to acquire both keyhole exit and weld pool images from backside of workpiece in controlled-pulse PAW. With a specially designed optical filter, the images of low-intensity weld pool and high-intensity keyhole exit are obtained simultaneously by one single CCD camera. The dynamic variations of both keyhole exit and weld pool are successfully monitored. The influences of welding current waveform parameters on the dimension and position of keyhole exit and weld pool are measured. The effects of the waveform parameters of the controlled pulse on the establishment/sustainment periods of keyhole exit and the positions of first/last keyhole exits in a pulse cycle are elucidated experimentally.

Similar content being viewed by others

References

Fortain JM (2008) Plasma welding evolution and challenges. IIW Doc XII-1948-08:1–11

Wu CS, Wang L, Ren WJ, Zhang XY (2014) Plasma arc welding: process, sensing, control and modeling. J Manuf Process 16(1):74–78. https://doi.org/10.1016/j.jmapro.2013.06.004

Wu CS, Jia CB, Chen MA (2010) A control system for keyhole plasma arc welding of stainless steel with medium thickness. Weld J 89(11):225s–231s

Zhang SB, Zhang YM (2001) Efflux plasma charge-based sensing and control of joint penetration during keyhole plasma arc welding. Weld J 80:157s–162s

Saad E, Wang H, Kovacevic R (2006) Classification of molten pool modes in variable polarity arc welding based on acoustic signature. J Mater Process Technol 174(1-3):127–136. https://doi.org/10.1016/j.jmatprotec.2005.03.020

Dong CL, Zhu YF, Zhang H, Shao YC (2001) Study on front side arc light sensing in keyhole mode plasma arc welding. Chin J Mech Eng 37(03):30–33. https://doi.org/10.3901/JME.2001.03.030

Zhang YM, Zhang SB, Liu YC (2001) A plasma cloud charge sensor for pulse keyhole process control. Meas Sci Technol 12(8):1365–1370. https://doi.org/10.1088/0957-0233/12/8/352

Zhang YM, Ma Y (2001) Stochastic modeling of plasma reflection during keyhole arc welding. Meas Sci Technol 12(11):1964–1975. https://doi.org/10.1088/0957-0233/12/11/328

Zhang YM, Zhang SB (1999) Observation of the keyhole during plasma arc welding. Weld J 75:53s–559

Liu ZM, Wu CS, Gao JQ (2013) Vision-based observation of keyhole geometry in plasma arc welding. Int J Therm Sci 63(1):38–45. https://doi.org/10.1016/j.ijthermalsci.2012.07.006

Liu ZM, Wu CS, Chen J (2013) Sensing dynamic keyhole behaviors in controlled-pulse keyholing plasma arc welding. Weld J 92(12):381-s–389-s

Zhang GK, Wu CS, Liu XF (2015) Single vision system for simultaneous observation of keyhole and weld pool in plasma arc welding. J Mater Process Technol 215(1):71–78. https://doi.org/10.1016/j.jmatprotec.2014.07.033

Zhang GK, Chen J, Wu CS (2017) Simultaneous sensing of weld pool and keyhole in controlled-pulse PAW. Weld J 96(3):95s–103s

Funding

The authors are grateful to the financial support for this research from the National Natural Science Foundation of China (Grant No. 50936003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Zhang, G., Wu, C. & Chen, J. Single CCD-based sensing of both keyhole exit and weld pool in controlled-pulse PAW. Weld World 62, 377–383 (2018). https://doi.org/10.1007/s40194-017-0541-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0541-y