Abstract

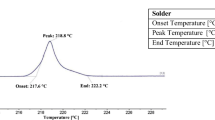

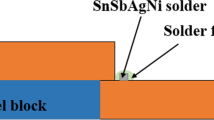

Properties of lead-free solder alloys and microstructural characterization of solder joints made from Sn1.0Ag0.5Cu1.0Bi and Sn0.9Ag0.5Cu0.9Bi1.0In (composition given in weight %) with Cu plate were widely studied in this work. The influence of Bi and In additions in these solder alloys was studied as well. The melting temperatures, diffluence and wetting properties, microstructures and costs were observed and evaluated. Thermo-Calc software was used for phase composition prediction. Altogether, 1500 cycles were carried out for the thermal cycling test in the range from +150 to −40 °C where the solder joints’ reliability was assessed due to practice requirement. Optical microscopy, scanning electron microscopy (EDX microanalysis) and shear strength test were used for the evolution of microstructure, structural integrity and mechanical strength of thermal-cycled solder joints. The reliability test results after temperature cycling indicate two lead-free solder alloys as the most convenient for soldering in the microelectronics industry.

Similar content being viewed by others

Change history

12 July 2018

In the original version of this article, the data displayed online in the “About this article” section for “Cite this article as:...,” the first and second name of the second author are incorrect.

References

Bastow E (2003) Five solder families and how they work. Adv Mater Processes 26–29

Choi S, Lee JG, Subramanian KN, Bieler TR, Lucas JP (2002) Microstructural characterization of damage in thermomechanically fatigued Sn-Ag based solder joints. J Electron Mater 31(4):292–297

Guo F, Lucas JP, Subramanian KN (2001) Creep behavior in Cu and Ag particle-reinforced composite and eutectic Sn-3.5Ag and Sn-4.0Ag-0.5Cu non-composite solder joints. J Mater Sci Mater Electron 12:27–35

Telang AU, Bieler TR, Mason DE, Subramanian KN (2003) Comparisons of experimental and computed crystal rotations caused by slip in crept and thermomechanically fatigued dual-shear eutectic Sn-Ag solder joints. J Electron Mater 32(12):1455–1462

Guo F, Choi S, Lucas JP, Subramanian KN (2001) Microstructural characterization of reflowed and isothermallyaged Cu and Ag particulate reinforced Sn-3.5Ag composite solders. Soldering Surf-Mount Technol 13(1):7–18

Metal prices all metal prices [online]. [cit. 2010–01-10]. <:http://www.metalprices.com/.>

Laurila T (2010) Impurity and alloying effects on interfacial reaction layers in Pb-free soldering, In Materials Science and Engineering: R: Reports, Corrected Proof

Rizvi JM (2005) Effect of alloying elements on properties and microstructures of SnAgCu solders. In Journal of Electronic Materials 34:1115–1122 [cit. 20.01.2011]

Šebo P (2008) Influence of thermal cycling on shear strength of Cu–Sn3.5AgIn–Cu joints with various content of indium. In Journal of Alloys and Compounds, 463, 1–2, Elsevier Science, 168–172

Cheng MD (2004) Intermetallic compounds formed during the reflow and aging of Sn-3.8Ag-0.7Cu and Sn-20ln-2Ag-0.5Cu solder ball grid array packages. In Journal of Electronic Materials 33(3):171–180 [cit. 20.05.2011]. <: http://www.scopus.com/.> ISSN 03615235

Satyanarayan KN Prabhu Reactive wetting, evolution of interfacial and bulk IMCs and their effect on mechanical properties of eutectic Sn-Cu solder alloy, In Advances in Colloid and Interface Science, In Press, Corrected Proof, Available online 17 May 2011, [cit. 20.06.2011]. <: http://www.scopus.com/.>ISSN 0001-8686

Niwat M, Kannachai K (2012) Evolution of intermetallic compounds between Sn-0.3Ag-0.7Cu low-silver lead-free solder and Cu substrate during thermal aging Original Research Article Journal of Materials Science & Technology 28 (1): 53–59

El-Daly AA, Hammad AE (2012) Enhancement of creep resistance and thermal behavior of eutectic Sn–Cu lead-free solder alloy by Ag and In-additions Original Research Article Materials & Design 40:292–298

Yang SC, Ho CE, Chang CW, Kao CR (2006) Rapid communication: strong concentration effect on the soldering reactions between Sn-based solders and Cu. J Material Research 21:2436–2439

Zhao J, Qi L, Wang X-M, Wang L (2004) Influence of Bi on microstructure evolution and mechanical properties in Sn–Ag–Cu lead-free solder. J Alloys Compd 375:196–201

Yen YW, Chou WT, Tseng YU, Lee C, Hsu CL (2008) Investigation of dissolution behavior of metallic substrates and intermetallic compound in molten lead-free solders. J Electron Mater 37:73–83

Chandra Rao BSS, Kumar KM, Zeng KY, Tay AAO, Kripesh V (2009) Effect of strain rate and temperature on tensile flow behaviour of SnAgCu nanocomposite solders. 11th Electronic Packaging Technology Conference (EPTC) 272–7

Yu DQ, Zhao J, Wang L (2004) Improvement on the microstructure stability, mechanical and wetting properties of Sn-Ag-Cu lead-free solder with the addition of rare earth elements. In Journal of Alloys and Compounds 376(1–2):170–175 [cit. 20.01.2011]. <: http://www.scopus.com/.>ISSN 0925-8388

Pan JJ, Akol XQ (2007) Development of new lead-free solder. In Welding Technology 36:55–56 [cit. 20.01.2011]. <: http://www.scopus.com/.>

Acknowledgments

This research is supported by VEGA Grant No. 1/0455/14, Grant No. APVV-0023/12 and OP for project Centre of Excellence of Five-axis Machining Experimental Base for High Tech Research ITMS 26220120045 and co-financed the by European Funds for Regional Development.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Beáta, Š., Erika, H. & Ingrid, K. Development of SnAgCu solders with Bi and In additions and microstructural characterization of joint interface. Weld World 61, 613–621 (2017). https://doi.org/10.1007/s40194-017-0446-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0446-9