Abstract

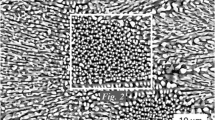

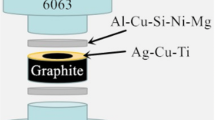

Aluminium matrix composites (AMC) are in the focus of recent research. In the field of lightweight design, dissimilar joints with AMC are of current interest. To ensure the positive properties of AMC—like high specific strength, increased wear resistance, and low coefficient of thermal expansion (CTE)—a suitable joining technique is necessary. This work shows the state of the art of arc brazing using a filler material of the alloying system Al-Ag-Cu. Joints of AMC/stainless steel and AMC/aluminium alloy are investigated. The formation of brittle Al-Fe intermetallic phases in AMC/stainless steel joints must be reduced to obtain a sufficient joint strength. Therefore, an adapted alloying concept is used for the filler material. The filler (40 wt% Al, 40 wt% Ag, and 20 wt% Cu) is alloyed with various contents of Si (1.2, 1.3, and 1.4 wt%). Primarily solidified Si can be seen above 1.3 wt% Si in the microstructure. The melting temperature could be reduced about 10 K by additional Si. The microstructure analyzed by SEM, EDXS, and XRD, as well as the hardness profile of the joining zone, are characterized and discussed. In case of the interface braze metal/aluminium material, the formation of a thin (approx. 5 μm) phase layer, consisting of solid solution of Al, can be seen. Compared with that insights, the phase layer at the interface braze metal/stainless steel consists of intermetallics of the system Fe-Al. The results of the hardness measurements at the interface and XRD patterns prove the presence of Fe3Al, FeAl, and FeAl3. Cracks can occur between the brittle phases FeAl and FeAl3, due to their high hardness of approx. 600 HV0.005 (rep. FeAl) and 1020 HV0.005 (rep. FeAl3) and in combination of internal stress formation during cooling.

Similar content being viewed by others

References

Xiu Z, Yang W, Chen G, Jiang L, Mac K, Wu G (2012) Microstructure and tensile properties of Si3N4p/2024Al composite fabricated by pressure infiltration method. Mat. a. Designs 33:350–358

Sajjadi SA, Ezatpour HR, Parizi MT (2012) Comparison of microstructure and mechanical properties of A356 aluminium alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mat a Designs 34:106–111

Qu X-h, Zhang L, Wu M, Ren S-b (2011) Review of metal matrix composites with high thermal conductivity for thermal management applications. Prog Nat Sci: Mater Int 21:189–197

Song JL, Lin SB, Yang CL, Ma GC, Liu H (2009) Spreading behavior and microstructure characteristics of dissimilar metals TIG welding–brazing of aluminum alloy to stainless steel. Mater Sci Eng A 509:31–40

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, Gambaro C (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26:41–46

Liu HW, Guo C, Cheng Y, Liu XF, Shao GJ (2006) Interfacial strength and structure of stainless steel–semi-solid aluminum alloy clad metal. Mater Lett 60:180–184

Steiners M, Höcker F (2007) Einfluss der Beschichtungen beim stoffschlüssigen Lichtbogen-fügen von Stahl mit Aluminium. Mat u Werkst 38:559–564

Dong H, Yang L, Dong C, Kou S (2010) Arc joining of aluminum alloy to stainless steel with flux-cored Zn-based filler metal. Mater Sci Eng A 527:7151–7154

Lin SB, Song JL, Yang CL, Fan CL, Zhang DW (2010) Brazability of dissimilar metals tungsten inert gas butt welding–brazing between aluminum alloy and stainless steel with Al–Cu filler metal. Mater Des 31:2637–2642

Prater T (2011) Solid-state joining of metal matrix composites: a survey of challenges and potential solutions. Mat a Man Proc 26:636–648

Lean PP, Gil L, Ureña A (2003) Dissimilar welds between unreinforced AA6082 and AA6092/SiC/25p composite by pulsed-MIG arc welding using reinforced filler alloys (Al-5Mg and Al-Si). J Mat Proc Tech 143-144:846–850

Ureña A, Escalera MD, Gil L (2000) Influence of interface reactions on fracture mechanisms in TIG arc-welded aluminium matrix composites. Comp Scien a Tech 60:613–622

Qin G, Lei Z, Su Y, Fu B, Meng X, Lin S (2014) Large spot laser assisted GMA brazing-fusion welding of aluminium alloy to galvanized steel. J Mat Proc Tech 214:2684–2692

Song JL, Lin SB, Yang CL, Ma GC, Liu H (2009) Spreading behavior and microstructure characteristics of dissimilar metals TIG welding-brazing of aluminum alloy to stainless steel. Mat Scien a Eng: A 509:31–40

Wielage B, Klose H (1995) Das Aluminiumlöten von Wärmetauschern. DVS-Reports 166:88–90

Wielage B, Martinez L (2001) Aluminiumlöten bei 550 °C – Eigenschaften von ZnAl-Verbindungen. DVS-Reports 212:214–217

Wielage B, Trommer F (2003) Löten von Aluminium mit Zinkbasisloten. Schweiß u Schneid 5:273–275

Song JL, Lin SB (2009) Effects of Si additions on intermetallic compound layer of aluminum–steel TIG welding–brazing joint. J Alloys Compd 488:217–222

Elßner M, Weis S, Grund T, Hausner S, Wielage B. and Wagner G (2014)"Lichtbogenlöten von Aluminiummatrix-Verbundwerkstoffen mit AlAgCu-Loten", Werkstoffe und werkstofftechnische Anwendungen, 52, ISBN 978–3–00-046877-3.

Elßner M, Weis S, Wagner G (2015) Joining of aluminum matrix composites and stainless steel by arc brazing. Mater Sci Forum 825-826:393–400

Czochralski J (1918) Ein neues Verfahren zur Messung der Kristallisationsgeschwindigheit der Metalle. Z phys Chemie 92:219–221

Potesser M, Schoeberl T, Antrekowitsch H and Bruckner J ( 2006) The characterization of the intermetallic Fe-Al layer of steel-aluminum weldings", EPD Congress, pp. 167–176.

Acknowledgements

The authors gratefully acknowledge the funding by the German Research Foundation (Deutsche Forschungs-gemeinschaft, DFG) within the framework of the Collaborative Research Centre 692 (SFB HALS 692).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Elßner, M., Weis, S., Wagner, G. et al. Joining of material compounds of aluminium matrix composites (AMC) by arc brazing using Al-Ag-Cu system filler alloy. Weld World 61, 405–411 (2017). https://doi.org/10.1007/s40194-016-0421-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0421-x