Abstract

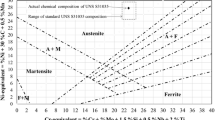

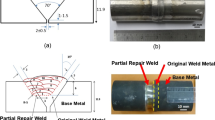

India has embarked on a mission programme for setting-up a coal-fired 800 MWe Advanced Ultra Super Critical (AUSC) power plant with steam parameters of 710/720 °C temperature and 30,400 kPa pressure. To implement this programme, India-specific version of 304HCu austenitic stainless steel (SS) and nickel-base Alloy 617M boiler tubes has been developed in collaboration with Indian manufacturers. The objective of the present study is to choose the appropriate gas tungsten arc (GTA) welding consumable for welding of 304HCu SS/304HCu SS and 304HCu SS/Alloy 617M dissimilar weld joints. Welding procedure specification (WPS) was prepared by using three types of filler wires, viz. ER304HCu, ERNiCrMo-3 and ERNiCrCoMo-1, for the 304HCu SS tube weld joints and ERNiCrCoMo-1 for the 304HCu SS/Alloy 617M dissimilar tube weld joints. Welding procedure qualification (WPQ) was carried out as per ASME Sec. IX requirements. Tube weld joints were also fabricated for evaluation of mechanical properties and for microstructural characterisation. Based on the detailed evaluation of mechanical properties, including creep, ER304HCu has been chosen for the similar welding of 304HCu SS and ERNiCrCoMo-1 for the dissimilar metal welding between 304HCu SS and Alloy 617M.

Similar content being viewed by others

References

SA-213/SA-213M (2010) Specification for seamless ferritic and austenitic alloy-steel boiler, super heater, and heat-exchanger tubes, American Society of Mechanical Engineer (ASME) Boiler and Pressure Vessel Code – Section II, Part A, p 315–327

Jayakumar T, Bhaduri AK, Chetal SC (2014) Development of improved high temperature boiler materials for the Indian advanced ultra super-critical thermal power plant technology. In: Lecomte-Beckers J, Dedry O, Oakey J, Kuhn B (eds) Proceedings of the 10th Liege Conference on Materials for Advanced Power Engineering, Belgium, p 51–60

Viswanathan R et al (2008) U.S. Program on materials technology for Ultra super-critical Coal-fired Boilers. In Advances in Materials Technology for Fossil Power Plants, Proceedings of the 5th International Conference, ASM International

Boiler grade DMV 304HCu (2008) Salzgitter Mannesmann Stainless Tubes 2

DuPont JN (2012) Microstructural evolution and high temperature failure of ferritic to austenitic dissimilar welds. Int Mater Rev 57(4):208–234

Zhu P, Zhao J-c, Chai X-y, Niu R-f, Zhao J, Liu Y-f. Research on the matching of Super 304H austenitic stainless steel material and the connector performance, Suzhou Nuclear Power Research Institute, Xi’an University of Technology, and Anhui No. 2 Electric Power Engineering Construction Co., Huainan

ASME Boiler and Pressure Vessel Code (2010), ASME Sec IX, Welding and brazing qualifications

Okada H, Sawaragi Y, Masuyama F, Komai N (2001) Mechanical properties and microstructure of 0.1C-18Cr-9Cr-3Cu-Nb-N steel tube after long term exposures in a power boiler. In Proceedings of 7th International Conference on Creep and Fatigue at Elevated Temperatures, The Japan Society of Mechanical Engineers, Tsukuba

Sawaragi Y, Ogawa K, Kato S, Natori A, Hirano S (1992) Development of the economical 18-8 stainless steel (Super 304H) having high elevated temperature strength for fossil fired boilers, The Sumitomo Research No. 48, Sumitomo Metal Industries, Ltd., Osaka and Tokyo, Japan

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Srinivasan, G., Dey, H.C., Ganesan, V. et al. Choice of welding consumable and procedure qualification for welding of 304HCu austenitic stainless steel boiler tubes for Indian Advanced Ultra Super Critical power plant. Weld World 60, 1029–1036 (2016). https://doi.org/10.1007/s40194-016-0359-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0359-z