Abstract

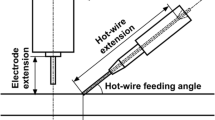

In the shipbuilding and bridge construction industries, shop primer paint is coated to the surface of steel plates in order to protect them from rusting during a long fabrication period. However, when arc welding is applied to the primer-coated plates, the arc heat may decompose and vaporize the coating. Then, the generated gas will be enclosed in the weld metal during the solidification process, causing the porosity defects, such as blowholes and the pits. In this study, the effects of penetration depth and non-penetrated joint root length on the generation of blowholes were clarified with various welding parameters. A new horizontal fillet welding process called ‘hybrid tandem MAG (HTM)’ was developed, a combination of a solid wire for the leading electrode and a flux-cored wire for the trailing electrode. The process features deep penetration and excellent porosity resistance. In order to reduce porosity in the fillet welding of primer-coated steel plate, it was found that the following measures are effective: (a) increasing the penetration depth and (b) decreasing the non-penetrated joint root length. The reduction of porosity by increasing the penetration depth is achieved by the formation of consistent ejection passage for vaporized gas. The phenomena mentioned above were verified by observing the interior of the weld pool directly by using an X-ray video camera. It is effective to reduce the leading electrode torch angle and to use a combination of high current and low voltage to create a buried arc to realize these measures. The MAG (HTM) procedure reduced the porosity formation to one tenth of that produced with the conventional tandem MAG process even at travel speeds up to 1600 mm/min.

Similar content being viewed by others

References

Kamata (1993) Primer paint varieties vs. porosity resistance. J Jpn Weld Soc 62:507

Kamata et al (1991) Development of a flux-cored wire for inorganic-zinc-primer painted steel plates. Prepr Natl Meet Jpn Weld Soc 48:78

Maki et al (1988) Development of a flux-cored wire for wash-primer painted steel plates. Prepr Natl Meet Jpn Weld Soc 43:234

Kurokawa (2000) Past and present developments in flux-cored wire for MAG welding. Kobe Steel Eng Rep 50(3):74–77

Izutani et al (2012) Blowholes reduction in GMAW of galvanized steel sheet: part 1. Prepr Natl Meet Jpn Weld Soc 90:92

Nakamura et al (2012) Blowholes reduction in GMAW of galvanized steel sheet: part 2. Prepr Natl Meet Jpn Weld Soc 90:94

Izutani et al New welding process suitable for galvanized steel in the automotive industry, “J-SolutionTM Zn,” Kobe Steel Eng Rep 63:(1):54-59

Yuan et al (2012) Development of deep penetration & low spatter hybrid tandem GMAW process (part 1). Prepr Natl Meet Jpn Weld Soc 90:8–9

Yuan et al (2013) Development of deep penetration & low spatter hybrid tandem GMAW process (part 2). Prepr Natl Meet Jpn Weld Soc 92:16–17

Yuan et al (2014) Development of deep penetration & low spatter hybrid tandem GMAW process (part 3: porosity resistance). Prepr Natl Meet Jpn Weld Soc 94:124–125

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Yuan, Y., Yamazaki, K. & Suzuki, R. Relationship between penetration and porosity in horizontal fillet welding by a new process “hybrid tandem MAG welding process”. Weld World 60, 515–524 (2016). https://doi.org/10.1007/s40194-016-0314-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0314-z