Abstract

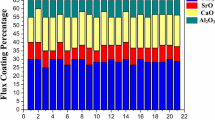

Five commercially available fluxes for submerged arc welding (SAW) were obtained from their manufacturers. The flux identities were coded to prevent identification. These were divided into small quantities and distributed to twelve laboratories for chemical analysis and classification according to ISO 14174:2012. The twelve laboratories were also coded to prevent identification of any particular data set with the participating laboratory. The round robin results showed high reproducibility of analysis of the major flux constituents used for classification, Al2O3, CaF2, Fe/FeO, MgO, MnO, SiO2, TiO2, and ZrO2, except for CaF2 with the flux Q that is high in iron. CaO is not analyzed according to ISO 14174:2012 but is calculated from whatever Ca remains after subtracting stoichiometric CaF2 based on F analysis. In most cases, more than one classification according to ISO 14174 could be assigned to a given flux by any of the participants, which is considered unsatisfactory for a classification system.

Similar content being viewed by others

Acknowledgments

The contributions of the flux suppliers ESAB Sweden, Kobelco Japan, Lincoln Electric USA and Voestalpine Bohler Welding Germany are gratefully acknowledged. Lincoln Electric USA provided the distribution of the samples for analysis. Also, the participation of the laboratories conducting analysis (ESAB Czech Republic, ESAB Sweden, ESAB USA, Fluxana Germany, Kobelco Japan, Lincoln Electric France, Lincoln Electric Netherlands, Lincoln Electric USA along with two separate unnamed independent laboratories Lincoln uses, Oerlikon Germany, and Voestalpine Bohler Welding Germany) is very much appreciated. The round robin would not have been possible without all of these contributions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Kotecki, D.J. IIW commission II round robin of flux analysis. Weld World 60, 373–382 (2016). https://doi.org/10.1007/s40194-016-0294-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0294-z