Abstract

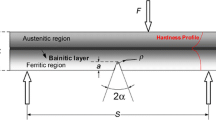

The influence of strength mismatch adjacent to the V-notch in Charpy specimen on stress field has been numerically analyzed with a 3D finite element method. It is found that the softer material adjacent to the V-notch provides a “shielding effect” from high-speed straining introduced by impact loading. As this leads to reduction in flow stress ahead of the V-notch, lower opening stress compared with homogeneous specimen is found in the case of the V-notch within the harder material in heterogeneous specimen. By contrast, in the case of the V-notch within the softer material, plastic strain is concentrated near the V-notch and the opening stress is elevated by constraint due to hard material adjacent to the V-notch. The Charpy impact test was conducted with the Charpy specimen extracted from the clad steel consisted of low- and high-strength steels in order to investigate the strength mismatch effect Charpy absorbed energy K V. It is found that K V value is affected by strength mismatch adjacent to the V-notch and the Weibull stress criterion can be applied to the quantitative evaluation of the strength mismatch effect on K V.

Similar content being viewed by others

References

Tamura H (1966) Notch toughness of weld heat-affected zones for high strength steels and low temperature service steels. J Jpn Weld Soc 35:710–724 (in Japanese)

Satoh K, Toyoda M (1982) Fracture toughness evaluation of welds with mechanical heterogeneity. Trans Jpn Weld Soc 13:30–37

Seo K, Masaki J (1982) Physical interpretation for the upper shelf energy of weld zone in Charpy impact test. J Jpn Weld Soc 51:291–297 (in Japanese)

Seo K, Masaki J, Nogata F, Satoh K (1983) Effect of mechanical heterogeneity on the ductile-to-brittle transition behavior of weld metal in Charpy impact test. Q J Jpn Weld Soc 1:123–129 (in Japanese)

Satoh K, Toyoda M, Minami F et al (1985) Effect of mechanical heterogeneity on fracture toughness evaluation of steel welds. Trans Jpn Weld Soc 16:170–177

Seo K, Nogata F, Masaki J (1986) The absorbed energy in Charpy impact test for specimens with mechanical heterogeneity. J Soc Mater Sci Jpn 35:1405–1410 (in Japanese)

Mathur KK, Needleman A, Tvergaard V (1999) Dynamic 3D analysis of the Charpy V-notch test. Model Simul Mater Sci Eng 1:467–484

Besson J, Madi Y, Motarjemi A et al (2005) Crack initiation and propagation close to the interface in a ferrite-austenite joint. Mater Sci Eng A 397:84–91

Bennett PE, Sinclair GM (1966) Parameter representation of low-temperature yield behavior of body-centered cubic transition metals. Trans Am Soc Mech Eng 88:518–524

Japan Welding Engineering Society: BE-committee research report, (1975)

Toyosada M, Gotoh K, Sagara K (1991) Temperature rise distribution near a crack tip due to plastic work under high loading rate. J Soc Naval Architects Jpn 170:651–663 (in Japanese)

Nakamura T, Shih CF, Freund LB (1986) Analysis of a dynamically loaded three-point-bend ductile fracture specimen. Eng Fract Mech 25:323–339

Vargas PM, Dodds RH Jr (1995) Strain rate and inertial effects on impact loaded single-edge notch bend specimens. ASTM STP 1256(26):715–731

Beremin FM (1983) A local criterion for cleavage fracture of a nuclear pressure vessel steel. Metall Mater Trans A 14A:2277–2287

Minami F, Brückner-Foit A, Trolldenier B (1990) Numerical procedure for determining Weibull parameters based on the local approach. Proc 8th Euro Conf on Fracture, ECF8. pp. 76–81.

Ruggieri C, Minami F, Toyoda M, Hagiwara Y, Inoue T (1992) Local approach to notch depth dependence of CTOD results. J Soc Naval Architects Jpn 171:493–499

Minami F, Brückner-Foit A, Munz D, Trolldenier B (1992) Estimation procedure for the Weibull parameters used in the local approach. Int J Fract 54:197–210

Minami F, Iida M, Takahara W, Konda N, Arimochi K (2002) Fracture mechanics analysis of Charpy test results based on the Weibull stress criterion. Eur Struct Integr Soc 30:411–418

Rossoll A, Berdin C, Prioul C (2002) Determination of the fracture toughness of a low alloy steel by the instrumented Charpy impact test. Int J Fract 114:205–226

Takashima Y, Ohata M, Minami F (2006) Evaluation method for fracture mechanics-based material toughness from Charpy impact test. Mater Sci Forum 512:61–66

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2529, recommended for publication by Commission X “Structural Performances of Welded Joints—Fracture Avoidance”

Rights and permissions

About this article

Cite this article

Takashima, Y., Yamada, Y.S., Handa, T. et al. Numerical analysis of strength mismatch effect on stress field in Charpy specimen. Weld World 59, 433–441 (2015). https://doi.org/10.1007/s40194-014-0217-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0217-9