Abstract

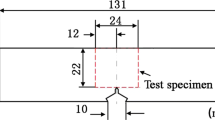

There have been reports on fatigue cracking of steel bridges, especially old bridges such as constructed in the 1970s. At that time, less attention of weld quality was paid. Weld defects of the poor quality of welded joints can be crack initiation points. Judgment whether a fatigue cracking occurs or not from a weld defect is very important in terms of appropriate maintenance work under limited time and cost. This study aims at discriminating between fatigue crack and weld defect by ultrasonic nondestructive test. During fatigue crack growth, the opening phenomenon is known. Crack tip displacement increases according to the loading level. That can be observed by the echo height. Cruciform specimens of double bevel welded joints were prepared. Each of the specimens had an incomplete penetration by remaining root face. Tensile force was applied to the specimens. During loading, the ultrasonic instrumentation was set up and echo heights were measured. By the subtraction of the images between loading and non-loading conditions, the tip of a crack was localized successfully.

Similar content being viewed by others

References

Arakawa T, Hirose S, Senda T (1985) The detection of weld cracks using ultrasonic testing. NDT Int 18(1):9–16

Bouami D, Vadder DD (1986) Detection and measurement of crack closure and opening by an ultrasonic method. Eng Fract Mech 23(5):913–920

Busse LJ, Collins HD, Doctor SR (1984) The emerging technology of synthetic aperture focusing for ultrasonic testing, ASME Paper, 84-PVP-122

Harumi K, Uchida M, Miyajima T, Ogura Y (1992) Defect sizing of small inclined cracks on a free surface using multi-tip waves. NDT&E Int 25(3):135–144

Langenberg K-J, Marklein R, Mayer K (2012) Ultrasonic nondestructive testing of materials theoretical foundations. CRC Press, Taylor & Francis Group

Lorenz M, van der Wal LF, Berkhout AJ (1991) Ultrasonic imaging with multi-SAFT; nondestructive characterization of defects in steel components. Nondestruc Test Eval 6:149–177

Makabe C, Purnowidodo A, McEvily AJ (2004) Effects of surface deformation and crack closure on fatigue crack propagation after overloading and underloading. Int J Fatigue 26:1341–1348

McClung RC, Sehitoglu H (1989) On the finite element analysis of fatigue crack closure—2. Num Res Eng Fract Mech 33:253–272

Miki C, Onishi R, Kubota T, Hanji T (2010) Radiation characteristics of ultrasonic tip echo and its application to detect fatigue crack closure in welding residual stress fields. J Jpn So Civ Eng A 66(2):219–228

Morikawa H, Shimozato T, Miki C, Ichikawa A (2002) Study on fatigue cracking in steel bridge piers with box section and temporally repairing. J Jpn Soc Civil Eng. No.703/I-59, pp 177–184

Sehitoglu H (1985) Crack opening and closure in fatigue. Eng Fract Mech 21:329–339

Thompson RB (1983) Quantitative ultrasonic evaluation methods. J App Mech 50(4b):1191–1201

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2464, recommended for publication by Commission XIII “Fatigue of Welded Components and Structures”.

Rights and permissions

About this article

Cite this article

Shirahata, H., Miki, C., Yamaguchi, R. et al. Fatigue crack detection by the use of ultrasonic echo height change with crack tip opening. Weld World 58, 681–690 (2014). https://doi.org/10.1007/s40194-014-0149-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0149-4