Abstract

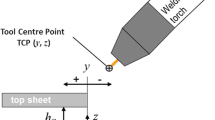

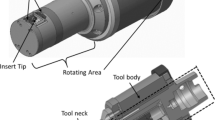

MAG welding is widely used for thin sheet metal applications such as car body structures due to its ability to tolerate a fair amount of deviation of the components from the ideal shape. In MAG welding, the process window is sufficiently large to accommodate the expected component tolerances. In practice, however, quality control is an issue since most welds are produced with parameters outside of the optimum range, especially in the case of automated MAG welding. To ensure best performance, a robust real-time control law is needed that adapts critical process parameters to the changing conditions, most notably the variation in gap height. Here, the gap-dependent adaptive control algorithm for the deposition of filler material and the related energy input comes into play. With an optical sensor that is mounted in front of the torch, the system measures the actual position of the two components in real-time during the entire welding process and the controller adapts the relevant parameters accordingly using a dynamic process model. This optimization ensures that only the required filler material is used and the associated energy input is tightly controlled to assure best quality even in a fully automated welding process.

Similar content being viewed by others

References

FANUC ROBOTICS, SERVRO-ROBOT (2005) Adaptive Welding. Litho, (FRA-12/05) - Company publication

Meyer R (2011) Erhöhung der Prozesssicherheit durch Beherrschung der Bauteilabweichungen beim Fügen im Karosseriebau, Increased process reliability by controlling the component variations in welding in car bodywork. Dissertation, University of Technology Dresden, TUD press, Dresden (in German)

Allen TT, Richardson RW, Tagliabue DP, Maul GP (2002) Statistical process design for robotic GMA welding of sheet metal. Weld J 81:69–77

Ebert-Spiegel M, Goecke SF (2013) Efficient Gap filling in MAG welding by using optical sensors. 16th International Conference on Joining Materials, Helsingør-Denmark

Allen C, Shi S, Hilton P (2011) Adaptively controlled high brightness laser-arc hybrid welding. Weld Cut 10:318–321

Allen C, Hilton P, Blackburn J (2012) Increasing the tolerance to fit-up gap using hybrid laser-arc welding and adaptive control of welding parameters. 37th MATADOR Conference

Bölmsjo G, Pires N, Loureiro A (2006) Welding Robots—Technology, System Issues and Applications. Springer, London

Maas N (2012) Anpassung von Schweißparametern auf der Grundlage messbarer Stoßgeometrien, Adjustment of welding parameters on the basis of measurable butt geometries. Master thesis, University Duisburg-Essen (in German)

Boillot JP (2012) Clever Vision Systems for the New Generation of Welding Robots. Visual JW2012-1:26

Paul C (2011) Virtuelle Roboter-Programmierung in der Serienfertigung – Unterstützung durch moderne Sensortechnik, Virtual robot programming in series production - support through advanced sensor technology. DVS-Ber Band 279:86–90 (in German)

Weise J (2011) Einführung einer Schweißrobotertechnologie zur Fertigung von Großbaugruppen aus Al-Legierungen, Introduction of a welding robot technology for the production of large assemblies of Al alloys. DVS-Ber Band 279:23–28 (in German)

Roosen S (1997) Online-Prozeßoptimierung beim MAG-Schweißen mit Hilfe eines Expertensystems, On-line process optimization for GMAW using an expert system. Dissertation, RWTH Aachen (in German)

Reisgen U, Beckers M, Buchholz G, Willms K (2013) Progress towards model based optimisation of gas metal arc welding processes. Weld World 56(9):35–40, Doc. IIW-2306

Chen SB, Zhang Y, Qiu T, Lin T (2003) Robotic welding systems with vision-sensing and self-learning neuron control of arc welding dynamic process. J Intell Robot Syst 36(2):191–208

Horber H, Haug K (1999) Führung von MSG-Schweißprozessen mit laser-optischem 2D-Abstandssensor und intelligenter Fuzzy-Signalverarbeitung, Guiding of GMA welding processes using laser-optical 2D distance sensors and intelligent fuzzy signal processing. DFMRS Forschungsbericht 99(1):87–106 (in German)

Kurth J, Wild W (2002) Passive optische Sensoren zur Fugenvermessung beim Metall-Schutzgas-Schweißen, Passive Optical Sensors for the Groove-Detection at Metal-Arc-Welding. tm -Tech Mess 69(4):174–180

Reek A (2000) Strategien zur Fokus-positionierung beim Laserstrahlschweißen, Strategies for focus positioning in laser welding. Dissertation, University of Technology Munich (in German)

Ussing S, Christensen HK, Honoré M (2013) Adaptive control of weld process in wind turbine tower manufacturing. JOM-17:VII

Kurth J (2001) Ein Beitrag zur Fugenverfolgung und -geometriebestimmung mit prozessinterner Sensorik und optischen CMOS-Detektoranordnungen, A contribution to the joint tracking and geometry specifications with in-process sensors and optical CMOS detector arrays. Dissertation, University Rostock (in German)

Harwig DD (1996) Weld parameter development of robot welding. Society of Manufacturing Engineers Technical Papers 291:189–207

Daeves K (1953) Werkstoff-Handbuch Stahl und Eisen, materials-manual steel and iron. Verlag Stahleisen, Düsseldorf (in German)

Schellhase M (1985) Der Schweißlichtbogen - ein technologisches Werkzeug, The welding arc—a technological tool. DVS-Verlag, Düsseldorf (in German)

Goecke SF, Krautwald A (2005) ENERWELD—Effiziente thermische Fügeverfahren, Efficient thermal joining processes. Krautwald Projektberater, Bremen (in German)

Wu CS (2010) Welding thermal processes and weld pool behaviors. CRC Press, London

Ulrich D (2005) Schweißtechnische Fertigungsverfahren 2—Verhalten der Werkstoffe beim Schweißen, Welding manufacturing methods 2 - Behavior of the materials during welding. Springer, Heidelberg (in German)

Kim IS, Basu A (1998) A mathematical model of heat transfer and fluid flow in the gas metal arc welding process. J Mater Process Technol 77(1):17–24

Lancaster JF (1999) Metallurgy of welding. Abington Publishing, Cambridge

Rykalin (1957) Berechnung der Wärmevorgänge beim Schweißen, calculation of heat transactions during welding. Verlag Technik, Berlin (in German)

Beckert M, Probst R (1973) Beitrag zu technologischen Problemen des Schmelzschweißprozesses, contribution to technological problems of the welding process. Wiss Z TH Magdeburg 17(3/4):383–392 (in German)

Huismann G (2002) Advantages in using the stick out for increasing the burn off rate in gas metal arc welding. Doc. IIW-212-1026-02

Matthes KJ, Richter E (2012) Schweißtechnik—Schweißen von metallischen Konstruktionswerkstoffen, welding technology - Welding of metallic construction materials. Hanser, Munich (in German)

Löhr M, Harada S, Tong H, Ueyama T, Ushio M (2002) Verbesserung der Spaltüberbrückbarkeit beim Dünnblechschweißen durch das MIG-/MAG-P-Wechselstromverfahren, process improvement in the ability to bridge gaps in thin sheet welding by MIG-/MAG-P-AC. DVS Kongressbd 220:233–238 (in German)

Acknowledgement

The authors would like to thank the German Federal Ministry of Education and Research (BMBF) for the support of the research work carried out within the scope of the program ‘Research at Universities of Applied Science’, as directive of ‘Qualification of young engineers’.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2460, recommended for publication by Commission XII ‘Arc Welding Processes and Production Systems’.

Rights and permissions

About this article

Cite this article

Ebert-Spiegel, M., Goecke, SF. & Rethmeier, M. Efficient gap filling in MAG welding using optical sensors. Weld World 58, 637–647 (2014). https://doi.org/10.1007/s40194-014-0145-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0145-8