Abstract

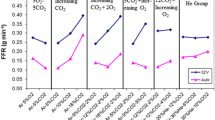

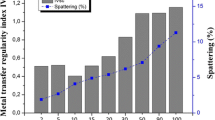

The operating parameters of the short-circuiting MAG process are expected to have a significant effect on fume generation. Despite this, no conclusive results on this subject have been presented in current literature. The objective of this work was to determine the most significant governing parameters affecting fume generation, by attempting to isolate each parameter from the others as much as possible. Several welding tests were carried out, and the effect of short-circuiting current, arc length (welding voltage), arcing time, and droplet diameters before detachment were investigated. The results show that the increase in each of these parameters contributes to a higher fume generation rate, and their effect becomes more significant when they act together.

Similar content being viewed by others

References

Scotti A, Ponomarev V, Lucas W (2012) A scientific application oriented classification for metal transfer modes in GMA welding. J Mater Process Technol 212(6):1406–1413. doi:10.1016/j.jmatprotec.2012.01.021

Dennis JH, Hewitt PJ, Redding CAJ, Workman AD (2001) A model for prediction of fume formation rate in Gas Metal Arc Welding (GMAW), globular and spray modes, DC electrode positive. Ann Occup Hyg 45(2):105–113

Zimmera AT, Barona PA, Biswasb P (2002) The influence of operating parameters on number-weighted aerosol size distribution generated from a gas metal arc welding process. J Aerosol Sci 33:519–531

Bosworth MR, Deam RT (2000) Influence of GMAW droplet size on fume formation rate. J Phys D Appl Phys 33:2605–2610

Meneses VA, Gomes JFP, Scotti A (2014) The effect of metal transfer stability (spattering) on fume generation, morphology and composition in Short-Circuit MAG Welding. J Mater Proc Technol 214(7):1388–1397. doi:10.1016/j.jmatprotec.2014.02.012

Hilton DE, Plumridge PN (1991) Welding and metal fabrication, 59, 555

Cooper P, Godbole A, Norrish J (2007) Modelling and simulation of gas flows in arc welding—implications for shielding efficiency and fume extraction. Soldag Insp São Paulo 12(4):336–345

Mendez PF, Jenkins NT, Eagar TW (2000) Effect of electrode droplet size on evaporation and fume generation in GMAW. Proceedings of the Gas Metal Arc Welding for the 21st Century Conference, Orlando, FL, December 6–8, 2000, 8 p

Yamazaki K, Yamamoto E, Suzuki K, Koshiishi F (2007) Effects of welding process parameters on fume emission in gas metal arc welding, IIW Doc no. XII-1922-07

Heile RF, Hill DC (1975) Particulate fume generation in arc welding processes. Weld J 54(7):201s–210s

Sterjovski Z, Brossier J, Thoisy E, Cuiuri D, Norrish J, Monaghan BJ (2006) An investigation of particulate weld fume generated from the GMAW of plain carbon steel. Australas Weld J 51(1):34–40

Sterjovski Z, Norrish J, Monaghan BJ (2010) The effect of voltage and metal transfer mode on particulate fume size during the GMAW of plain carbon steel. Weld World 54(9–10):R249–R256. doi:10.1007/BF03266737

Pires I, Quintino L, Miranda RM, Gomes JFP (2006) Fume emissions during gas metal arc welding. Toxicol Environ Chem 88(3):385–394

Garcia RP, Scotti A (2010) Comparative analysis of fume generation between solid (GMAW) and flux cored wires (FCAW). Soldag Insp 15(2):103–111

Gray CN, Hewitt PJ, Dare PRM (1982) New approach would help control welding fumes at source (MIG and MMA)—part two: MIG fumes. Welding and Metal Fabrication, 1982, October, 393–397

AWS, F1.2:2006. Laboratory method for measuring fume generation rates and total fume emission of welding and allied processes. AWS, USA, 24 p (ISBN 0-87171-031-5)

ASTM, ASTM C800 (2008) Standard Specification for fibrous glass blanket insulation (aircraft type), American Society for Testing and Materials, 5 p

Rezende GMC, Liskévych O, Vilarinho LO, Scotti A (2011) A criterion to determine voltage setting in short-circuit GMAW. Soldagem Insp 16(2):98–103. (ISSN 0104-9224 printed/ISSN 1980-6973 on-line), doi:10.1590/S0104-92242011000200002. (In Portuguese)

Scotti A, Rezende GMC, Liskévych O (2011) Measurement of metal transfer regularity as a means of selecting parameters in GMAW with short-circuiting, IIIW Commission XII/SG 212 Intermediate Meeting, Trollhättan, Sweden, 21–24 March, 2011, Doc XII-2008-11, 10 p

Quimby JB, Ulrich GD (1999) Fume formation rates in gas-shielded metal arc welding. Weld J 78(4):142–149

Rosado T, Pires I, Quintino L (1999) Opportunities to reduce fume emissions in gas metal arc welding, IIW Doc. VIII–2094-09

Wallace M, Landon D, Song R, Echt A (2001) Case studies: a field evaluation of the effect of pulsed arc welding technique on reducing worker exposures. Appl Occup Environ Hyg 16(2):93–97. doi:10.1080/104732201460127

Pires I, Quintino L, Amaral V, Rosado T (2010) Reduction of fume and gas emissions using innovative gas metal arc welding variants. Int J Adv Manuf Technol 50(5–8):557–567. doi:10.1007/s00170-010-2551-4

Acknowledgments

The authors would like to express their gratitude to the Federal University of Uberlandia, Brazil, through its Center for Research and Development of Welding Processes (Laprosolda), for the laboratory support for fume quantification. They also would like thanking the Brazilian councils for research development, CAPES, and CNPq for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2437, recommended for publication by Commission XII “Arc Welding Processes and Production Systems.”

Rights and permissions

About this article

Cite this article

Scotti, A., de Meneses, V.A. Governing parameters affecting fume generation in short-circuit MAG welding. Weld World 58, 367–376 (2014). https://doi.org/10.1007/s40194-014-0122-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0122-2