Abstract

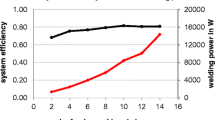

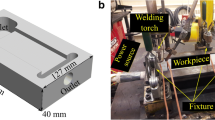

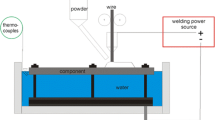

Within this manuscript, the energy balance for gas-shielded arc welding processes based on experimental investigations is discussed. The energy input into the joint is measured using a novel calorimetric system. Energy losses of the welding arc due to conduction, convection, and radiation are determined using a double-walled bell-shaped measurement system. Cooling losses of the welding equipment are recorded by a measurement unit integrated in the cooling system. The energy balance is determined for a set of different process and welding parameters. The influence of each parameter on the energy balance is systematically studied and illustrated. Measurements confirm that it is possible to increase the efficiency of welding processes, for example by reducing the wire feed speed, using helium gas, or increasing the distance of the welding torch to the metal plate. Contrarily, increasing the current or voltage, or reducing the shielding gas flow, reduces the process efficiency. The difference between the lowest and highest achievable value of efficiency can be more than 15 % for one specific welding process. Analysis revealed two main causes for energy losses: first, the radiation, convection, and conduction losses of the arc, and second, the cooling losses in the welding torch and the current-carrying ground cable. By summation of the three measured energy shares—heat input in the component; radiation, convection, and conduction losses of the arc; and the heat dissipation into the cooling system of the welding source—95 % of the total energy flow can be described and visualized. This knowledge increases the understanding of the joining process and also allows drawing conclusions on energy-saving capabilities.

Similar content being viewed by others

References

DIN EN 1011–1 (2009) Welding—recommendations for welding of metallic materials—part 1: General guidance for arc welding; German version EN 1011–1

SAI GLOBAL (1993) SEW 088:1993, supplemental sheet 2: Weldable fine grained steels; guidelines for processing, particular for fusion welding

Cantin F (2005) Arc power and efficiency in gas tungsten arc welding of aluminum. Sci Technol Weld Joi 10(5):200–210

Ghent HW, Roberts DW, Hermance CE, Kerr HW, Strong AB (1979) Arc efficiencies in TIG welds. Arc Physics and Weld Pool Behavior—International Conference of the Welding Institute, London, pp. 17–23, 8–10. May 1979

Becker, Rieger (1956) Schweißkalorimetrie [Teil 1], (welding calorimetrie [part 1]); 47. Mitteilung aus dem ZIS, Schweißtechnik, 6. Jahrgang, issue 1, pp. 12–15 (in German)

Giedt WH, Tallerico LN, Fuerschbach PW (1989) GTA welding efficiency: calorimetric and temperature field measurements. Weld J 68:28s–32s

DuPont JN, Marder AR (1995) Thermal efficiency of arc welding processes. Weld J 74:406s–416s

Fuerschbach PW (1998) Cathodic cleaning and heat input in variable polarity plasma arc welding of aluminum. Weld J 77:76s–85s

Joseph A, Harwig D, Farson DF, Richardson R (2003) Measurement and calculation of arc power and heat transfer efficiency in pulsed gas metal arc welding. Sci Technol Weld Joi 8(6):400–406

Pépe N, Egerland S, Colegrove PA, Yapp D, Leonhartsberger A, Scotti A (2011) Measuring the process efficiency of controlled gas metal arc welding processes. Sci Technol Weld Joi 16(5):412–417

Gött, Kozakov, Schöpp (2010) Plasmadiagnostik am Beispiel des Schweißlichtbogens (Plasma diagnostics using the example of the welding arc), DVS Congress, pp. 340–345, ISBN 978-3-87155-592-3

Acknowledgments

This work was part of research project IGF Nr. 15.562B/DVS-Nr. 03.0378 of the research coalition “Deutscher Verband für Schweißen und verwandte Verfahren e.V.” (DVS) and was promoted by the program for industrial alliance research (IGF). The financial support by the “German Federal Ministry of Research and Technology” via the consortium “AiF” is gratefully acknowledged. The Cluster of Excellence “Energy-Efficient Product and Process Innovation in Production Engineering” (eniPROD®) is funded by the European Union (European Regional Development Fund) and the Free State of Saxony. Further studies could be conducted only by promoting by the Excellence Initiative of the Chemnitz University of Technology “eniPROD”. For this, promotion and support are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2391, recommended for publication by Commission XII "Arc Welding Processes and Production Systems"

Rights and permissions

About this article

Cite this article

Haelsig, A., Mayr, P. Energy balance study of gas-shielded arc welding processes. Weld World 57, 727–734 (2013). https://doi.org/10.1007/s40194-013-0073-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0073-z