Abstract

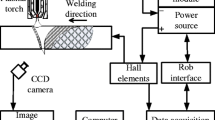

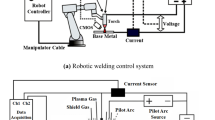

To overcome the shortcomings of conventional plasma arc welding (PAW), the “controlled pulse keyholing” strategy is proposed and the waveform-controlled keyhole PAW system is developed. To deeply understand the dynamic behaviors of keyhole in this novel PAW process, it is essential to measure and monitor the dynamic variation information of the keyhole geometry in real time. In this study, a vision system is developed to acquire the images of the keyhole from the underside of the workpiece. When a fully penetrated keyhole (open keyhole) is formed, clear keyhole images are captured. Both CCD camera and an efflux plasma voltage sensor are used to measure and characterize the keyhole shape and size during the waveform-controlled PAW process. The dynamic variation features of keyhole shape in a pulse cycle are visualized. The phenomena of “one keyhole in each pulse” and periodic partial-open keyhole transformation are experimentally sensed. The observation results lay solid foundation for controlling keyhole stability and optimizing the process parameters in keyhole plasma arc welding.

Similar content being viewed by others

References

Raymond TN. Plasma welding-in the 90s. Proc. of IIW Asian Pacific Welding Congress, 4–9 Feb. 1996, Auckland, New Zealand, pp. 237–249

Fortain JM. Plasma welding evolution & challenges. IIW Doc. XII-1948-08, 2008, pp. 1–11

Martikainen JK, Moisio TJI (1993) Investigation of the effect of welding parameters on weld quality of plasma arc keyhole welding of structural steels. Weld J 72(7):329s–340s

Vilkas EP (1991) Plasma arc welding of exhaust pipe system components. Weld J 70(4):49–52

Mendez PF. New trends in welding in the aeronautic industry. Proc. of New Trends for the Manufacturing in the Aeronautic Industry, 24–25 May, 2000, San Sebastian, Spain, pp. 21–38

Irving B (1992) Plasma arc welding takes on the advanced solid rocket motor. Weld J 71(12):49–52

Keanini RG, Rubinsky B (1990) Plasma arc welding under normal and zero gravity. Weld J 69(6):41–50

Zhang YM, Zhang SB (1999) Observation of the keyhole during plasma arc welding. Weld J 75(2):53s–59s

Metcalfe JC, Quigley MBC (1975) Keyhole stability in plasma arc welding. Weld J 54(11):401s–404s

Wu CS, Jia CB, Chen MA (2010) A control system for keyhole plasma arc welding of stainless steel with medium thickness. Weld J 89(11):225s–231s

Steffens HD, Kayser K (1972) Automatic control for plasma arc welding with constant keyhole diameter. Weld J 51:408–418

Zhang SB, Zhang YM (2001) Efflux plasma charge-based sensing and control of joint penetration during keyhole plasma arc welding. Weld J 80:157s–162s

Saad E, Wang H, Kovacevic R (2006) Classification of molten pool modes in variable polarity arc welding based on acoustic signature. J Mater Process Technol 174:127–136

Chen Q, Sun ZG, Sun Wand J, Wang YW (2004) Closed-loop control of welding penetration in keyhole plasma arc welding. Trans Nonferrous Metals Soc of China 14:116–120

Zhang YM, Zhang SB, Liu YC (2001) A plasma cloud charge sensor for pulse keyhole process control. Meas Sci Technol 12:1365–1370

Dong CL, Zhu YF, Zhang H, Shao YC (2001) Study on front side arc light sensing in keyhole mode plasma arc welding. Chin J Mech Eng 37:30–33

Zhang YM, Ma Y (2001) Stochastic modeling of plasma reflection during keyhole arc welding. Meas Sci Technol 12:1964–1975

Saeed G, Zhang YM (2007) Weld pool surface depth measurement using a calibrated camera and structured light. Meas Sci Technol 18:2570–2578

Wu CS, Gao JQ, Wang DM (2011) Observation of weld pool profiles in short-circuiting gas metal arc welding. Proc Instn Mech Engrs, Part B: J Eng Manuf 225:1873–1887

Wu CS, Zhong LM, Gao JQ (2009) Visualization of hump formation in high speed gas metal arc welding. Meas Sci Technol 20:115702, 8pp

Remy F, Sonia S, Frederic C, Francis B (2005) Study of keyhole behavior for full penetrated Nd-YAG CW laser welding. J Phys D: Appl Phys 38:1881–1887

Krasnoperov MY, Pieters RRGM, Richardson IM (2004) Weld pool geometry during keyhole laser welding of thin steel sheets. Sci Technol Weld Join 9:501–506

Fujinage S, Takenaka H, Narikiyo T, Katayama S, Matsunawa A (2000) Direct observation of keyhole behavior during pulse modulated high-power Nd:YAG laser irradiation. J Phys D: Appl Phys 33:492–497

Li L, Brookfield DJ, Steen WM (1996) Plasma charge sensor for in-process non-contact monitoring of laser welding process. Meas Sci Technol 7:615–626

Jia CB, Wu CS, Zhang YM (2009) Sensing controlled pulse key-holing condition in plasma arc welding. Trans Nonferrous Met Soc China 19(2):341–346

Liu ZM, Wu CS, Chen MA (2012) Visualizing the influence of the process parameters on the keyhole dimensions in plasma arc welding. Meas Sci Technol 23:105603, 9pp

Acknowledgments

The authors are grateful to the financial support for this research from the National Natural Science Foundation of China (Key Program Grant No. 50936003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2390, recommended for publication by Commission XII “Arc Welding Processes and Production Systems.”

Rights and permissions

About this article

Cite this article

Liu, Z.M., Wu, C.S. Visualization of dynamic keyhole behavior in waveform-controlled plasma arc welding. Weld World 57, 719–725 (2013). https://doi.org/10.1007/s40194-013-0072-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0072-0