Abstract

Introduction

Tolerances in the design of adhesive joints were determined and their influence on the mechanical behaviour of adhesively bonded steel joints under quasi-static and under cyclic loads was evaluated in this work.

Test preparation and test performance

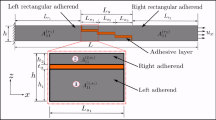

The paper focuses on adhesive layer thickness, filling ratios, and surface treatments as the main production tolerances. They were varied at different levels. Four different bondline thicknesses, three different filling ratios, and two different surface treatments were investigated. The influence of tolerances was analysed on single-lap shear joints and peel joints. Toughened epoxy-based adhesives were used. Mechanical properties of bonded steel joints were investigated under static load and under cyclic load.

Results

In both load cases, adhesive layer thickness has the highest influence on the resulting shear strength. Peel strength decreased with reduced filling ratios.

Conclusions

The influence of adhesive layer thickness on fatigue could be predicted by shift factors. Furthermore, it was possible to describe the influence of production tolerances in an analytical way. This allows an evaluation of fatigue based on quasi-static tests.

Similar content being viewed by others

Abbreviations

- f :

-

Frequency

- f :

-

Number of degrees of freedom

- F a :

-

Load amplitude

- F max :

-

Maximum force

- k :

-

Slope of Woehler curve

- l :

-

Total length

- l f :

-

Free length

- l o :

-

Overlap length

- m :

-

Number of factor levels

- n :

-

Population

- N :

-

Number of cycles

- N 10 :

-

Number of cycles (10 % failure probability)

- N 90 :

-

Number of cycles (90 % failure probability)

- P max :

-

Maximum load of the fatigue cycle

- P min :

-

Minimum load of the fatigue cycle

- RT:

-

Room temperature

- R :

-

Load ratio

- s :

-

Standard deviation

- t :

-

Adherend thickness

- t a :

-

Adhesive layer thickness

- T :

-

Temperature

- v :

-

Velocity

- w :

-

Width

References

Ashcroft IA, Wahab Abdel MM, Crocombe AD, Hughes DJ, Shaw SJ (2001) The effect of environment on the fatigue of bonded composite joints. Part 1: testing and fractography. Compos Part A 32:45–58

Broughton WR, Mera RD, Hinopoulos G (1999) Cyclic fatigue testing of adhesive joints: test method assessment, NPL Report, Project PAJ3—combined cyclic loading and hostile environments. Centre for Materials Measurement & Technology, Teddington

Crocombe AD, Richardson G (1999) Assessing stress state and mean load effects on the fatigue response of adhesively bonded joints. Int J Adhes Adhes 19(1):19–27

Lee DG, Kim KS, Im YT (1991) An experimental study of fatigue strength for adhesively bonded tubular single lap joints. J Adhes 35(1):39–53

Melander A, Larsson M, Stensiok H, Gustavsson A, Linder J (2000) Fatigue performance of weldbonded high strength sheet steels tested in Arctic, room temperature and tropical environments. Int J Adhes Adhes 20(5):415–425

Stoyack JE, Chan WS (1994) The effects of temperature and frequency on the fatigue properties of film adhesives. A collection of technical papers/35th AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference, Paper-no.: AIAA 94–1589, Part 4, 2159

Wirth C (2004) Calculation concept of joint strength in car body models, “Berechnungskonzept für die Klebflanschfestigkeit in Gesamtkarosseriemodellen” (in German), PhD Thesis, TU Munich

Kahraman R, Sunar M, Yilbas B (2008) Influence of adhesive thickness and filler content on the mechanical performance of aluminium single-lap joints bonded with aluminium powder filled epoxy adhesive. J Mater Process Technol 205(2):183–189

Grant LDR, Adams RD, da Lucas Silva FM (2009) Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry (2009). Int J Adhes Adhes 29(5):535–542

da Silva LFM, Rogridues TNSS, Figueiredo MAV, de Moura MFSF, Chousal JAG (2006) Effect of type and thickness on the lap shear strength. J Adhes 82(11):1091–1115

Carlberger T, Stigh U (2010) Influence of layer thickness on cohesive properties of an epoxy-based adhesive—an experimental study. J Adhes 86(8):816–835

Adnan A, Sun CT (2008) Effect of adhesive thickness on joint strength: a molecular dynamics perspective. J Adhes 84(5):401–420

De Morais AB, Pereira AB, Teixeira JP, Cavaleiro NC (2007) Strength of epoxy adhesive-bonded stainless-steel joints. Int J Adhes Adhes 27(8):679–686

Deng J, Lee MMK (2008) Effect of plate end and adhesive spew geometries on stresses in retrofitted beams bonded with a CFRP plate. Composites: Part B 39(4):731–739

Feih S, Shercliff HR (2005) Adhesive and composite failure prediction of single-L joint structures under tensile loading. Int J Adhes Adhes 25(1):47–59

von Hayek-Boelingen M (2004) Ways of contamination tolerant adhesive bonding, “Wege zum kontaminationstoleranten Kleben” (in German), PhD Thesis, University of Bundeswehr Munich

Kleppmann W (2006) Handbook Design of Experiment, “Taschenbuch Versuchsplanung” (in German). Carl Hanser, Munich

Acknowledgments

This work was technically and financially supported by FOSTA e.V., Düsseldorf, financed from Stiftung Stahlanwendungsforschung, Essen, Germany.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2324, recommended for publication by Commission XVI “Polymer Joining and Adhesive Technology”.

Rights and permissions

About this article

Cite this article

Teutenberg, D., Hahn, O. Predicting production influences on adhesively bonded joints subjected to cyclic load. Weld World 57, 203–213 (2013). https://doi.org/10.1007/s40194-012-0015-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-012-0015-1