Abstract

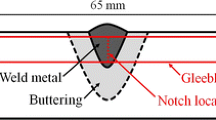

Due to the increasing use of high-strength steels, the requirements for filler materials are also growing. To investigate the toughness properties of the corresponding welded joints, a new testing method has to be developed. This new test method uses subsized Charpy-V specimens (abbr. KLST samples) which permit the analysis of welded sheets with a thickness of approx. 5 mm. For the development and evaluation of the new method, a high-strength steel (S690) and a high-strength filler metal (T 69 5 ZMn2NiCrMo M M1 H5) were used. Physical simulations of various post-weld heat treatment cycles and multipass welding were conducted in a dilatometer. After the heat treatment, the toughness of the specimens was tested by Charpy impact testing and the hardness with Vickers hardness measurements. Additional metallographic investigations were also carried out. The results show that the method provides useful results for a wide range of parameters and it is appropriate for the simulation of post-weld heat treatment cycles and multipass welding on welded joints.

Similar content being viewed by others

References

Kaiser H-J, Kern A, Grill R, Schlosser H, Schlosser H, Schröter F (2008) Heavy plates made from special structural steels for highest requirements. Stahl und Eisen 128(Nr. 4):91–97, in German

Keehen E, Karlsson L, Andren H-O (2006) Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals. Sci Technol Weld Joi 11:1–24

Bohle SD, Nemade JB, Collins L, Collins L, Liu C (2006) Effect of nickel and molybdenum additions on weld metal toughness in a submerged arc welded. HSLA line-pipe steel 173:92–100

Uwer D, Uwer D, Degenkolbe J, Herr D, Herr D (1992) Schweißen moderner hochfester Baustähle. Stahl und Eisen 112(Nr. 4):29–35

Schnitzer, R., G. Posch, M. Fiedler, C. Strauß, R. Rauch, T. Fössl, B. Böck (2011) New developed filler metals for new voestalpine AG high strength steels. Proceedings of 64th IIW Annual Assembly & International Conference, Chennai, India (2011)

Pontremoli M, Pontremoli M, Weber L, Dilg C, Schwinn V, Knauf G, Lippe M, Ehrhardt B, Finger M (2006) High-strength steels for plates, pipes and sections. Stahl und Eisen 126(Nr. 4):63–77

DIN EN 10045 Teil1 (1990) Charpy impact test on metallic materials part 1: test method

Towers OL (1986) Testing sub-size Charpy specimens, part 1—the influence of thickness on the ductile/brittle transition. Met Constr 18(3):171–186

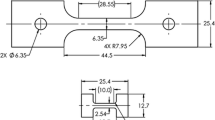

Schlagradl T, Schneider R, Posch G, Schnitzer R (2011) Development of a toughness testing method for the effect of short heat treatment cycles on high-strength filler materials using subsized charpy V-specimens. BHM 156(Nr. 3):93–98, in German

DIN 50115 (1991) Notched bar impact testing of metallic materials using test pieces other than ISO test pieces

Towers OL (1986) Testing sub-size Charpy specimens, part 3—the adequacy of current code requirements. Met Constr 8(5):319R–325R

Schneider, H.-C (2005) Development of a miniaturized fracture-toughness specimen for post-irradiation experiments, Dissertation Universität Karlsruhe (in German)

Wallin K (2001) Upper shelf energy normalization for sub-sized Charpy-V specimens. Int J Pres Ves Pip 78(7):463–470

Rauch, R., W. Ernst, T. Hribernig and G. Auberger (2006) voestalpine welding calculator, voestalpine Stahl GmbH, Linz

Hollomon JH, Jaffe LD (1945) Time-temperature relations in tempering steels, trans. AIME 162:223–249

Eisenhüttenleute VD (ed): (1993) Steel. A handbook for materials research and engineering, volume 2: applications. Springer, Düsseldorf

R.F. Decker, S. Floreen (1988) Maraging steels: recent developments and applications. In: Wilson R.K. (ed.). TMS, Warrendale, pp. 1–38

Sha W, Cerezo A, Smith GDW (1993) Metall Trans A 24:1221–1232

Ping DH, Ohnuma M, Hirakawa Y, Kadoya Y, Hono K (2005) Mater Sci Eng A 394:285–295

Acknowledgments

Financial support of the Austrian “Österreichische Forschungsförderungsgesellschaft (FFG)” in framework of the project “Welding of High Strength Steels” is thankfully acknowledged by the authors of this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2270, recommended for publication by Commission II “Arc Welding and Filler Metals”.

Rights and permissions

About this article

Cite this article

Schlagradl, T., Schneider, R., Posch, G. et al. Investigation of the hardness–toughness relationship of a welded joint after different heat treatment cycles. Weld World 57, 113–121 (2013). https://doi.org/10.1007/s40194-012-0012-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-012-0012-4