Abstract

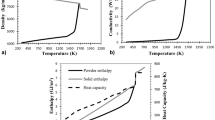

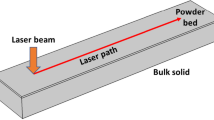

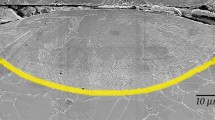

Laser powder bed fusion (LPBF), also called selective laser melting, is an additive manufacturing technology with great potential for creating three-dimensional metallic components with intricate designs. The application of dynamic thermal cycles involving melting and cooling makes it difficult to maintain the desired surface quality and shape in the LPBF process. The LPBF process's dynamic stability of the melt pool is essential to ascertain due to its influence on the quality of the manufactured products. Examining the thermal behavior and temperature distribution inside the melt pool is necessary. Subsequent to experimental validation, employing a finite element model (FEM) has the potential to accurately define thermal distributions and the dimensions of the melt pool. A three-dimensional transient model based on a moving Gaussian heat source was employed in this study to examine the influence of process variables (i.e., scan velocity, laser power, laser beam radius, hatch spacing, number of layers, and scan angle for each layer) on the melt pool shape in LPBF of SS316L powder. A finite element model based on three-dimensional parameters was proposed to evaluate the temperature gradient and melt pool characteristics of SS316L when subjected to laser powder bed fusion. The method takes into account the effect of the laser penetration depth on the characteristics of the molten pool, determined by a multiple-layer (15) and multiple-track (6) finite element model with variable process parameters, such as laser power, scanning speed, beam radius and hatch spacing. Experimental data obtained from the literature were used to calibrate the proposed heat source model, and the adjusted finite element model was then validated through further experiments. The modeling results showed concordance with the experimental data. The effects of the interlayer and intertrack were examined. Temperature distributions for each track and layer and the depth, width and length of the melt pool were evaluated, and the observed values for each variable were analyzed. The average melt pool length, width, and depth were determined to have relative errors of 1.88%, 1.49%, and 2.12%, respectively, between the FEM model and experimentally measured dimensions for an optimal range of varied process parameters.

Similar content being viewed by others

Abbreviations

- k :

-

Thermal conductivity [W/(m·°C)]

- Q :

-

Heat generation per volume (W/m3)

- ρ :

-

Material density (kg/m3)

- q :

-

Conduction heat transfer (W/m2)

- \({q}_{\mathrm{c}}\) :

-

Convection heat transfer (W/m2)

- \({q}_{\mathrm{r}}\) :

-

Radiation heat transfer (W/m2)

- c :

-

Specific heat capacity [J/(kg·°C)]

- H :

-

Convection heat coefficient [W/(m2 °C)]

- \(\varepsilon \) :

-

Emissivity

- \(\sigma \) :

-

Stefan–Boltzmann constant

- \({T}_{o}\) :

-

Ambient temperature (0 \(^\circ{\rm C} \))

- \({T}_{\mathrm{room}}\) :

-

Room temperature (\(^\circ{\rm C} \))

- T :

-

Medium temperature (\(^\circ{\rm C} \))

- \({k}_{\mathrm{p}}\) :

-

Material thermal conductivity in powder state [W/(m·°C)]

- \({k}_{\mathrm{s}}\) :

-

Material thermal conductivity in solid state (W/(m·°C)

- \({\rho }_{\mathrm{s}}\) :

-

Material density in powder state (kg/m3)

- \({\rho }_{\mathrm{p}}\) :

-

Material density in solid state (kg/m3)

- φ :

-

Material porosity

- H :

-

Enthalpy (J/m3)

- \(\eta \) :

-

Laser absorptivity

- R :

-

Laser beam radius (µm)

- V :

-

Laser scan velocity (mm/s)

- S :

-

Laser penetration depth

- P :

-

Laser power (W)

- t :

-

Laser run time (s)

- \(n\) :

-

Number of layers

- H :

-

Layer thickness (µm)

- X, Y, Z :

-

Coordinate system

References

Huang Y, Yang L, Du X, Yang Y (2016) Finite element analysis of thermal behavior of metal powder during selective laser melting. Int J Therm Sci 104:146–157

Yadroitsev I, Yadroitsava I, Bertrand P, Smurov I (2012) Factor analysis of selective laser melting process parameters and geometrical characteristics of synthesized single tracks. Rapid Prototyp J 18:201–208

Gupta MK et al (2020) Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy. J Market Res 9(5):9506–9522

Ali H, Ghadbeigi H, Hosseinzadeh F, Oliveira J, Mumtaz K (2019) Effect of pre-emptive in situ parameter modification on residual stress distributions within selective laser-melted Ti6Al4V components. Int J Adv Manuf Technol 103(9):4467–4479

Yap CY et al (2015) Review of selective laser melting: Materials and applications. Appl Phys Rev 2(4):041101

Clare AT, Chalker PR, Davies S, Sutcliffe CJ, Tsopanos S (2008) Selective laser melting of high aspect ratio 3D nickel–titanium structures two way trained for MEMS applications. Int J Mech Mater Des 4(2):181–187

Wong M, Tsopanos S, Sutcliffe CJ, Owen I (2007) Selective laser melting of heat transfer devices. Rapid Prototyp J 13:291–297

Vandenbroucke B, Kruth JP (2007) Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp J 13:196–203

Rochus P, Plesseria J-Y, Van Elsen M, Kruth J-P, Carrus R, Dormal T (2007) New applications of rapid prototyping and rapid manufacturing (RP/RM) technologies for space instrumentation. Acta Astronaut 61(1–6):352–359

Hollander DA et al (2006) Structural, mechanical and in vitro characterization of individually structured Ti–6Al–4V produced by direct laser forming. Biomaterials 27:955–963

Khanna N, Mistry S, Rashid RR, Gupta MK (2019) Investigations on density and surface roughness characteristics during selective laser sintering of Invar-36 alloy. Mater Res Express 6(8):086541

Xiong Z, Liu S, Li S, Shi Y, Yang Y, Misra R (2019) Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater Sci Eng A 740:148–156

Hussein A, Hao L, Yan C, Everson R (2013) Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater Des 1980–2015(52):638–647

Denlinger ER, Gouge M, Irwin J, Michaleris P (2017) Thermomechanical model development and in situ experimental validation of the laser powder-bed fusion process. Addit Manuf 16:73–80

Zohdi TI (2017) Modeling and simulation of functionalized materials for additive manufacturing and 3d printing: continuous and discrete media: continuum and discrete element methods. Springer, Berlin

Alghamdi A, Downing D, McMillan M, Brandt M, Qian M, Leary M (2019) Experimental and numerical assessment of surface roughness for Ti6Al4V lattice elements in selective laser melting. Int J Adv Manuf Technol 105(1):1275–1293

Jiang H-Z et al (2019) Factor analysis of selective laser melting process parameters with normalised quantities and Taguchi method. Opt Laser Technol 119:105592

Liu J et al (2020) Effect of scanning speed on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater Des 186:108355

Yadroitsev I, Gusarov A, Yadroitsava I, Smurov I (2010) Single track formation in selective laser melting of metal powders. J Mater Process Technol 210(12):1624–1631

Kusuma C, Ahmed SH, Mian A, Srinivasan R (2017) Effect of laser power and scan speed on melt pool characteristics of commercially pure titanium (CP-Ti). J Mater Eng Perform 26(7):3560–3568

Craeghs T, Bechmann F, Berumen S, Kruth J-P (2010) Feedback control of Layerwise laser melting using optical sensors. Phys Procedia 5:505–514

Gusarov A, Yadroitsev I, Bertrand P, Smurov I (2007) Heat transfer modelling and stability analysis of selective laser melting. Appl Surf Sci 254(4):975–979

Childs T, Hauser C, Badrossamay M (2005) Selective laser sintering (melting) of stainless and tool steel powders: experiments and modelling. Proc Inst Mech Eng Part B J Eng Manuf 219(4):339–357

Grossmann A, Felger J, Froelich T, Gosmann J, Mittelstedt C (2019) Melt pool controlled laser powder bed fusion for customised low-density lattice structures. Mater Des 181:108054

Yasa E, Deckers J, Kruth JP (2011) The investigation of the influence of laser re-melting on density, surface quality and microstructure of selective laser melting parts. Rapid Prototyp J 17:312–327

Shi X, Ma S, Liu C, Wu Q (2017) Parameter optimization for Ti–47Al–2Cr–2Nb in selective laser melting based on geometric characteristics of single scan tracks. Opt Laser Technol 90:71–79

Zaeh MF, Branner G (2010) Investigations on residual stresses and deformations in selective laser melting. Prod Eng Res Devel 4(1):35–45

Parry L, Ashcroft I, Wildman R (2019) Geometrical effects on residual stress in selective laser melting. Addit Manuf 25:166–175

Carraturo M, Lane B, Yeung H, Kollmannsberger S, Reali A, Auricchio F (2020) Numerical evaluation of advanced laser control strategies influence on residual stresses for laser powder bed fusion systems. Integrat Mater Manuf Innov 9:435–445

Leitz K-H, Singer P, Plankensteiner A, Tabernig B, Kestler H, Sigl L (2017) Multi-physical simulation of selective laser melting. Met Powder Rep 72(5):331–338

Song B, Dong S, Liao H, Coddet C (2012) Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int J Adv Manuf Technol 61(9):967–974

Zhang D, Zhang P, Liu Z, Feng Z, Wang C, Guo Y (2018) Thermofluid field of molten pool and its effects during selective laser melting (SLM) of Inconel 718 alloy. Addit Manuf 21:567–578

Li Z, Xu R, Zhang Z, Kucukkoc I (2018) The influence of scan length on fabricating thin-walled components in selective laser melting. Int J Mach Tools Manuf 126:1–12

Manvatkar V, De A, DebRoy T (2014) Heat transfer and material flow during laser assisted multi-layer additive manufacturing. J Appl Phys 116(12):124905

Carraturo M, Kollmannsberger S, Reali A, Auricchio F, Rank E (2021) An immersed boundary approach for residual stress evaluation in selective laser melting processes. Addit Manuf 46:102077

Matsumoto M, Shiomi M, Osakada K, Abe F (2002) Finite element analysis of single layer forming on metallic powder bed in rapid prototyping by selective laser processing. Int J Mach Tools Manuf 42(1):61–67

Luo Z, Zhao Y (2019) Numerical simulation of part-level temperature fields during selective laser melting of stainless steel 316L. Int J Adv Manuf Technol 104(5):1615–1635

Chen H, Wei Q, Wen S, Li Z, Shi Y (2017) Flow behavior of powder particles in layering process of selective laser melting: Numerical modeling and experimental verification based on discrete element method. Int J Mach Tools Manuf 123:146–159

Chen H, Wei Q, Zhang Y, Chen F, Shi Y, Yan W (2019) Powder-spreading mechanisms in powder-bed-based additive manufacturing: Experiments and computational modeling. Acta Mater 179:158–171

Ma L, Bin H (2007) Temperature and stress analysis and simulation in fractal scanning-based laser sintering. Int J Adv Manuf Technol 34(9):898–903

Chiumenti M et al (2017) Numerical modelling and experimental validation in selective laser melting. Addit Manuf 18:171–185

Nickel A, Barnett D, Prinz F (2001) Thermal stresses and deposition patterns in layered manufacturing. Mater Sci Eng, A 317(1–2):59–64

Artinov A, Bachmann M, Rethmeier M (2018) Equivalent heat source approach in a 3D transient heat transfer simulation of full-penetration high power laser beam welding of thick metal plates. Int J Heat Mass Transf 122:1003–1013

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Yan W et al (2017) Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater 134:324–333

Foroozmehr A, Badrossamay M, Foroozmehr E, Golabi SI (2016) Finite element simulation of selective laser melting process considering optical penetration depth of laser in powder bed. Mater Design 89:255–263

Neiva E et al (2020) Numerical modelling of heat transfer and experimental validation in powder-bed fusion with the virtual domain approximation. Finite Elem Anal Des 168:103343

Dai K, Shaw L (2002) Distortion minimization of laser-processed components through control of laser scanning patterns. Rapid Prototyp J 8:270–276

Yang JHN, Brandt M, Sun SJ (2009) Numerical and experimental investigation of the heat-affected zone in a laser-assisted machining of Ti–6Al–4V alloy process. In: Materials science forum, 2009, 618: Trans Tech Publ, pp 143–146

Kollmannsberger S, Carraturo M, Reali A, Auricchio F (2019) Accurate prediction of melt pool shapes in laser powder bed fusion by the non-linear temperature equation including phase changes: model validity: isotropic versus anisotropic conductivity to capture AM Benchmark Test AMB2018-02. Integr Mater Manuf Innov 8:167–177

Yin J, Zhu H, Ke L, Lei W, Dai C, Zuo D (2012) Simulation of temperature distribution in single metallic powder layer for laser micro-sintering. Comput Mater Sci 53(1):333–339

Ibraheem AK, Derby B, Withers PJ (2002) Thermal and residual stress modelling of the selective laser sintering process. MRS Online Proceedings Library (OPL), 758

Shuai C, Feng P, Gao C, Zhou Y, Peng S (2013) Simulation of dynamic temperature field during selective laser sintering of ceramic powder. Math Comput Model Dyn Syst 19(1):1–11

Zhuang J-R, Lee Y-T, Hsieh W-H, Yang A-S (2018) Determination of melt pool dimensions using DOE-FEM and RSM with process window during SLM of Ti6Al4V powder. Opt Laser Technol 103:59–76

Verhaeghe F, Craeghs T, Heulens J, Pandelaers L (2009) A pragmatic model for selective laser melting with evaporation. Acta Mater 57(20):6006–6012

Sowdari D, Majumdar P (2010) Finite element analysis of laser irradiated metal heating and melting processes. Opt Laser Technol 42(6):855–865

Gong H, Xing X, Gu H (2019) Rheological properties of two stainless steel 316L powders for additive manufacturing. IOP Conf Ser Mater Sci Eng 689(1):012003

Huang W, Zhang Y (2019) Finite element simulation of thermal behavior in single-track multiple-layers thin wall without-support during selective laser melting. J Manuf Process 42:139–148

Loh L-E et al (2015) Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int J Heat Mass Transf 80:288–300

Liu S, Zhu J, Zhu H, Yin J, Chen C, Zeng X (2020) Effect of the track length and track number on the evolution of the molten pool characteristics of SLMed Al alloy: numerical and experimental study. Opt Laser Technol 123:105924

Liu Y, Zhang J, Pang Z (2018) Numerical and experimental investigation into the subsequent thermal cycling during selective laser melting of multi-layer 316L stainless steel. Opt Laser Technol 98:23–32

Mills KC (2002) Recommended values of thermophysical properties for selected commercial alloys. Woodhead Publishing, New York

Wood W, Deem H, Lucks D (1964) Handbook of high temperature materials, 3rd edn. Springer, Berlin

Brooks RF, Egry I, Seetharaman S, Grant D (2001) Reliable data for high-temperature viscosity and surface tension: results from a European project. High Temp High Pressur UK 33(6):631–637

Chen C et al (2019) The effect of process parameters on the residual stress of selective laser melted Inconel 718 thin-walled part. Rapid Prototyp J 25:1359–1369

Larimian T, Kannan M, Grzesiak D, AlMangour B, Borkar T (2020) Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater Sci Eng A 770:138455

Zhang X, Chen L, Zhou J, Ren N (2020) Simulation and experimental studies on process parameters, microstructure and mechanical properties of selective laser melting of stainless steel 316L. J Braz Soc Mech Sci Eng 42(8):1–14

Bertoli US, Wolfer AJ, Matthews MJ, Delplanque J-PR, Schoenung JM (2017) On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater Des 113:331–340

Huang Z, et al (2021) A new heat source model for selective laser melting simulations based on energy distribution on the powder layer and the surface of substrate. arXiv:2106.03482

Ahmed N, Barsoum I, Haidemenopoulos G, Al-Rub RA (2022) Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: a review. J Manuf Process 75:415–434

Khorasani M et al (2021) On the role of process parameters on meltpool temperature and tensile properties of stainless steel 316L produced by powder bed fusion. J Mater Res Technol 12:2438–2452

Heeling T, Cloots M, Wegener K (2017) Melt pool simulation for the evaluation of process parameters in selective laser melting. Addit Manuf 14:116–125

Tran H-C, Lo Y-L (2018) Heat transfer simulations of selective laser melting process based on volumetric heat source with powder size consideration. J Mater Process Technol 255:411–425

Gusarov A, Yadroitsev I, Bertrand P, Smurov I (2009) Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J Heat Transf 131:7

Li Y, Zhou K, Tan P, Tor SB, Chua CK, Leong KF (2018) Modeling temperature and residual stress fields in selective laser melting. Int J Mech Sci 136:24–35

Fukuyama H, Higashi H, Yamano H (2019) Thermophysical properties of molten stainless steel containing 5 mass% B4C. Nucl Technol 205(9):1154–1163

Trejos-Taborda J, Reyes-Osorio L, Garza C, del Carmen Zambrano-Robledo P, Lopez-Botello O (2022) Finite element modeling of melt pool dynamics in laser powder bed fusion of 316L stainless steel. Int J Adv Manuf Technol 120(5–6):3947–3961

Lee K-H, Yun GJ (2020) A novel heat source model for analysis of melt Pool evolution in selective laser melting process. Addit Manuf 36:101497

Hodge N, Ferencz R, Solberg J (2014) Implementation of a thermomechanical model for the simulation of selective laser melting. Comput Mech 54(1):33–51

Trejos-Taborda J, Reyes-Osorio L, Garza C, del Carmen Zambrano-Robledo P, Lopez-Botello O (2022) Finite element modeling of melt pool dynamics in laser powder bed fusion of 316L stainless steel. Int J Adv Manuf Technol 120(5):3947–3961

Acknowledgements

This study was carried out at the National University of Sciences and Technology. The authors wish to express sincere gratitude to the National University of Sciences and Technology, H-12, Islamabad.

Author information

Authors and Affiliations

Contributions

All the authors participated actively throughout the research process. Dr SHI Jaffery supervised the research. Mr AK carried out simulations, data analysis and sample printing and experimental evaluations and also compiled the first draft. Mr SD designed the design of experiments and process parameters, and Dr ZA and Mr SZH reviewed the final research paper draft.

Corresponding author

Ethics declarations

Conflicts of interest

The authors do not have any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khan, A., Jaffery, S.H.I., Hussain, S.Z. et al. Numerical and Experimental Characterization of Melt Pool in Laser Powder Bed Fusion of SS316l. Integr Mater Manuf Innov 12, 210–230 (2023). https://doi.org/10.1007/s40192-023-00302-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-023-00302-w