Abstract

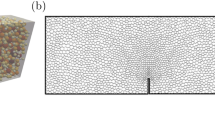

Reduced-order structure–property (S-P) linkages play a pivotal role in the tailored design of materials for advanced engineering components. There is a critical need to distill these from the simulation datasets aggregated using sophisticated, computationally expensive, physics-based numerical tools (e.g., finite element methods). The recent emergence of materials data science approaches has opened new avenues for addressing this challenge. In this paper, we critically compare the relative merits of the application of four distinct machine learning approaches for their efficacy in extracting microstructure-property linkages from the finite element simulation data aggregated on high-contrast elastic composites with different microstructures. The machine learning approaches selected for the study have included different combinations of local/global and parametric/nonparametric approaches. Furthermore, the nonparametric approaches selected for this study are based on Gaussian Process (GP) models that allow for a formal treatment of uncertainty quantification in the predicted values. The predictive performances of these different approaches have been compared against each other using rigorous cross-validation error metrics. Furthermore, their sensitivity to both the dataset size and dimensionality has been investigated.

Similar content being viewed by others

References

Materials genome initiative for global competitiveness. National science and technology council executive office of the president (2011)

van Schalkwijk W, Scrosati B (2007) Advances in lithium-ion batteries. Springer, Boston

Reed RC (2008) The superalloys: fundamentals and applications. Cambridge University Press, Cambridge

Hasegawa R (2000) Present status of amorphous soft magnetic alloys. J Magn Magn Mater 215:240–245

Furrer D, Fecht H (1999) Ni-based superalloys for turbine discs. JOM 51(1):14–17

Pollock T, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propul Power 22(2):361–374

Lu L, Han X, Li J, Hua J, Ouyang M (2013) A review on the key issues for lithium-ion battery management in electric vehicles. J Power Sources 226:272–288

Integrated computational materials engineering: a transformational discipline for improved competitiveness and national security. The National Academies Press, Washington (2008)

Mueller T, Kusne AG, Ramprasad R (2015) Machine learning in materials science: recent progress and emerging applications. Rev Comput Chem 29:186–273

Yang N, Yee J, Zheng B, Gaiser K, Reynolds T, Clemon L, Lu W, Schoenung J, Lavernia E (2017) Process-structure-property relationships for 316l stainless steel fabricated by additive manufacturing and its implication for component engineering. J Therm Spray Tech 26(4):610–626

Kalidindi S (2015) Hierarchical materials informatics: novel analytics for materials data. Elsevier, Boston

Yabansu YC, Steinmetz P, Hötzer J, Kalidindi S, Nestler B (2017) Extraction of reduced-order process-structure linkages from phase-field simulations. Acta Mater 124:182–194

Gomberg JA, Medford AJ, Kalidindi S (2017) Extracting knowledge from molecular mechanics simulations of grain boundaries using machine learning. Acta Mater 133:100–108

Gorgannejad S, Gahrooei MR, Paynabar K, Neu R (2019) Quantitative prediction of the aged state of ni-base superalloys using pca and tensor regression. Acta Mater 165:259–269

Olson GB (1997) Computational design of hierarchically structured materials. Science 277(5330):1237–1242

Panchal JH, Kalidindi S, McDowell DL (2013) Key computational modeling issues in integrated computational materials engineering. Comput Aided Des 45(1):4–25

Nellippallil AB, Rangaraj V, Gautham B, Singh AK, Allen JK, Mistree F (2017) A goal-oriented, inverse decision-based design method to achieve the vertical and horizontal integration of models in a hot rod rolling process chain. In: ASME 2017 International design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers, pp v02BT03a003–v02BT03a003

Fullwood D, Niezgoda S, Adams BL, Kalidindi S (2010) Microstructure sensitive design for performance optimization. Prog Mater Sci 55(6):477–562

Sanchez-Lengeling B, Aspuru-Guzik A (2018) Inverse molecular design using machine learning: Generative models for matter engineering. Science 361(6400):360–365

McDowell DL, Kalidindi S (2016) The materials innovation ecosystem: a key enabler for the materials genome initiative. MRS Bulletin 41(4):326–337

Mortazavi B, Baniassadi M, Bardon J, Ahzi S (2013) Modeling of two-phase random composite materials by finite element, mori–tanaka and strong contrast methods. Compos Part B Eng 45(1):1117–1125

Argatov II, Sabina FJ (2017) A two-phase self-consistent model for the grid indentation testing of composite materials. Int J Eng Sci 121:52–59

Duan H, Wang JX, Huang Z, Karihaloo BL (2005) Size-dependent effective elastic constants of solids containing nano-inhomogeneities with interface stress. J Mech Phys Solids 53(7):1574–1596

Fu SY, Feng XQ, Lauke B, Mai YW (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos Part B 39(6):933–961

Trofimov A, Drach B, Sevostianov I (2017) Effective elastic properties of composites with particles of polyhedral shapes. Int J Solids Struct 120:157–170

Fullwood D, Adams BL, Kalidindi S (2008) A strong contrast homogenization formulation for multi-phase anisotropic materials. J Mech Phys Solids 56(6):2287–2297

Pham D, Torquato S (2003) Strong-contrast expansions and approximations for the effective conductivity of isotropic multiphase composites. J Appl Phys 94(10):6591–6602

Mikdam A, Makradi A, Ahzi S, Garmestani H, Li DS, Remond Y (2009) Effective conductivity in isotropic heterogeneous media using a strong-contrast statistical continuum theory. J Mech Phys Solids 57(1):76–86

Adams BL, Kalidindi S, Fullwood D (2012) Microstructure sensitive design for performance optimization. Butterworth-Heinemann, Boston

Fernandez-Zelaia P, Joseph VR, Kalidindi S, Melkote SN (2018) Estimating mechanical properties from spherical indentation using bayesian approaches. Mater Des 147:92–105

Paulson NH, Priddy MW, McDowell DL, Kalidindi S (2017) Reduced-order structure-property linkages for polycrystalline microstructures based on 2-point statistics. Acta Mater 129:428–438

Li X, Xu Y, Chen S (2016) Computational homogenization of effective permeability in three-phase mesoscale concrete. Constr Build Mater 121:100–111

Pinz M, Weber G, Lenthe W, Uchic M, Pollock T, Ghosh S (2018) Microstructure and property based statistically equivalent rves for intragranular γ- γ’microstructures of ni-based superalloys. Acta Mater 157:245–258

Latypov MI, Kalidindi S (2017) Data-driven reduced order models for effective yield strength and partitioning of strain in multiphase materials. J Comput Phys 346(13):242–261

Gupta A, Cecen A, Goyal S, Singh AK, Kalidindi S (2015) Structure–property linkages using a data science approach: application to a non-metallic inclusion/steel composite system. Acta Mater 91:239–254

Jung J, Yoon JI, Park HK, Kim JY, Kim HS (2019) Bayesian approach in predicting mechanical properties of materials: Application to dual phase steels. Mater Sci Eng A 743:382–390

Iskakov A, Yabansu YC, Rajagopalan S, Kapustina A, Kalidindi S (2018) Application of spherical indentation and the materials knowledge system framework to establishing microstructure-yield strength linkages from carbon steel scoops excised from high-temperature exposed components. Acta Mater 144:758–767

Altschuh P, Yabansu YC, Hötzer J, Selzer M, Nestler B, Kalidindi S (2017) Data science approaches for microstructure quantification and feature identification in porous membranes. J Membr Sci 540(1):88–97

Mangal A, Holm EA (2018) Applied machine learning to predict stress hotspots i: face centered cubic materials. Int J Plast 111:122–134

Friedman J, Hastie T, Tibshirani R (2001) The elements of statistical learning, vol 1. Springer series in statistics. New York, NY, USA

Cecen A, Dai H, Yabansu YC, Kalidindi S, Song L (2018) Material structure-property linkages using three-dimensional convolutional neural networks. Acta Mater 146:76–84

Yang Z, Yabansu YC, Al-Bahrani R, Liao WK, Choudhary AN, Kalidindi SR, Agrawal A (2018) Deep learning approaches for mining structure-property linkages in high contrast composites from simulation datasets. Comput Mater Sci 151:278–287

Ryczko K, Mills K, Luchak I, Homenick C, Tamblyn I (2018) Convolutional neural networks for atomistic systems. Comput Mater Sci 149:134–142

Kondo R, Yamakawa S, Masuoka Y, Tajima S, Asahi R (2017) Microstructure recognition using convolutional neural networks for prediction of ionic conductivity in ceramics. Acta Mater 141:29–38

Fernandez-Zelaia P, Melkote SN (2019) Statistical calibration and uncertainty quantification of complex machining computer models. Int J Mach Tools Manuf 136:45–61

Yang Z, Yabansu YC, Jha D, Liao WK, Choudhary AN, Kalidindi SR, Agrawal A (2019) Establishing structure-property localization linkages for elastic deformation of three-dimensional high contrast composites using deep learning approaches. Acta Mater 166:335–345

Yabansu YC, Kalidindi S (2015) Representation and calibration of elastic localization kernels for a broad class of cubic polycrystals. Acta Mater 94:26–35

Landi G, Niezgoda S, Kalidindi S (2010) Multi-scale modeling of elastic response of three-dimensional voxel-based microstructure datasets using novel dft-based knowledge systems. Acta Mater 58(7):2716–2725

Kalidindi S, Niezgoda S, Landi G, Vachhani S, Fast T (2010) A novel framework for building materials knowledge systems. Comput Mater Continua 17(2):103–125

Cecen A, Yabansu YC, Kalidindi S (2018) A new framework for rotationally invariant two-point spatial correlations in microstructure datasets. Acta Mater 158:53–64

Niezgoda S, Kanjarla AK, Kalidindi S (2013) Novel microstructure quantification framework for databasing, visualization, and analysis of microstructure data. Integr Mater Manuf Innov 2(1):3

Niezgoda S, Fullwood D, Kalidindi S (2008) Delineation of the space of 2-point correlations in a composite material system. Acta Mater 56(18):5285–5292

Fullwood D, Niezgoda S, Kalidindi S (2008) Microstructure reconstructions from 2-point statistics using phase-recovery algorithms. Acta Mater 56(5):942–948

Turner DM, Niezgoda S, Kalidindi S (2016) Efficient computation of the angularly resolved chord length distributions and lineal path functions in large microstructure datasets. Model Simul Mater Sci Eng 24(7):075,002

Brough DB, Wheeler D, Kalidindi S (2017) Materials knowledge systems in python—a data science framework for accelerated development of hierarchical materials. Integr Mater Manuf Innov 6(1):36–53

Brough DB, Kannan A, Haaland B, Bucknall DG, Kalidindi S (2017) Extraction of process-structure evolution linkages from x-ray scattering measurements using dimensionality reduction and time series analysis. Integr Mater Manuf Innov 6(2):147–159

Bishop CM (2006) Pattern recognition and machine learning. Springer, Berlin

Witten IH, Frank E, Hall MA, Pal CJ (2016) Data mining: practical machine learning tools and techniques. Morgan Kaufmann, Cambridge

Binois M, Gramacy RB, Ludkovski M (2018) Practical heteroskedastic gaussian process modeling for large simulation experiments. J Comput Graph Stat 27(4):808–821

Tibshirani R (1996) Regression shrinkage and selection via the lasso. J R Stat Soc Ser B Methodol 58 (1):267–288

Härdle W (1990) Applied nonparametric regression 19. Cambridge University Press, Cambridge

Kvam PH, Vidakovic B (2007) Nonparametric statistics with applications to science and engineering, vol 653. Wiley, New Jersey

Cleveland WS (1979) Robust locally weighted regression and smoothing scatterplots. J Am Stat Assoc 74 (368):829–836

Cleveland WS, Devlin SJ (1988) Locally weighted regression: an approach to regression analysis by local fitting. J Am Stat Assoc 83(403):596–610

Ho TK (1995) Random decision forests. In: 1995 proceedings of the third international conference on document analysis and recognition, vol 1. IEEE, pp 278–282

Krige DG (1951) A statistical approach to some basic mine valuation problems on the witwatersrand. J South Afr Inst Min Metall 52(6):119–139

Matheron G (1963) Principles of geostatistics. Econ Geol 58(8):1246–1266

Sacks J, Welch WJ, Mitchell TJ, Wynn HP (1989) Design and analysis of computer experiments. Stat Sci 4(4):409–435

Rasmussen CE, Williams CK (2006) Gaussian processes for machine learning, vol 1. MIT Press, Cambridge

Ba S, Joseph VR et al (2012) Composite gaussian process models for emulating expensive functions. Ann Appl Stat 6(4):1838–1860

Joseph VR (2006) Limit kriging. Technometrics 48(4):458–466

Tuo R, Wu CJ, Yu D (2014) Surrogate modeling of computer experiments with different mesh densities. Technometrics 56(3):372–380

Santner TJ, Williams BJ, Notz WI (2013) The design and analysis of computer experiments. Springer, New York

Chen H, Loeppky JL, Welch WJ (2017) Flexible correlation structure for accurate prediction and uncertainty quantification in bayesian gaussian process emulation of a computer model. SIAM/ASA J Uncertain Quantif 5 (1):598–620

Banerjee S, Gelfand AE, Finley AO, Sang H (2008) Gaussian predictive process models for large spatial data sets. J R Stat Soc Ser B Stat Methodol 70(4):825–848

Gramacy RB, Lee HKH (2008) Bayesian treed gaussian process models with an application to computer modeling. J Am Stat Assoc 103(483):1119–1130

Duvenaud DK, Nickisch H, Rasmussen CE (2011) Additive gaussian processes. In: Advances in neural information processing systems, pp 226–234

Gramacy RB, Apley DW (2015) Local gaussian process approximation for large computer experiments. J Comput Graph Stat 24(2):561–578

Gramacy RB (2015) lagp: large-scale spatial modeling via local approximate gaussian processes in r. Journal of Statistical Software (available as a vignette in the laGP package)

Breiman L (2001) Random forests. Mach Learn 45(1):5–32

Chipman HA, George EI, McCulloch RE, et al. (2010) BART: Bayesian additive regression trees. Ann Appl Stat 4(1):266– 298

Yabansu YC, Kalidindi SR (2019) Microscale volume elements and their effective/homogenized stiffness parameter for high contrast 3-d elastic composite. https://matin.gatech.edu/resources/309

Funding

YCY and SRK received support from NSF 1761406. PFZ received financial support of the work from the Morris M. Bryan, Jr. Professorship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fernandez-Zelaia, P., Yabansu, Y.C. & Kalidindi, S.R. A Comparative Study of the Efficacy of Local/Global and Parametric/Nonparametric Machine Learning Methods for Establishing Structure–Property Linkages in High-Contrast 3D Elastic Composites. Integr Mater Manuf Innov 8, 67–81 (2019). https://doi.org/10.1007/s40192-019-00129-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-019-00129-4