Abstract

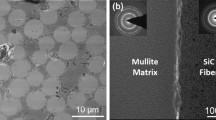

Layer-structured interphase, existing between reinforcing fiber and ceramics matrix, is an indispensable constituent for fiber-reinforced ceramic composites due to its determinant role in the mechanical behavior of the composites. However, the interphase may suffer high residual stress because of the mismatch of thermal expansion coefficients in the constituents, and this can exert significant influence on the mechanical behavior of the composites. Here, the residual stress in the boron nitride (BN) interphase of continuous SiC fiber-reinforced SiC composites was measured using a micro-Raman spectrometer. The effects of the residual stress on the mechanical behavior of the composites were investigated by correlating the residual stress with the mechanical properties of the composites. The results indicate that the residual stress increases from 26.5 to 82.6 MPa in tension as the fabrication temperature of the composites rises from 1500 to 1650 °C. Moreover, the increasing tensile residual stress leads to significant variation of tensile strain, tensile strength, and fiber/matrix debonding mode of the composites. The sublayer slipping of the interphase caused by the residual stress should be responsible for the transformation of the mechanical behavior. This work can offer important guidance for residual stress adjustment in fiber-reinforced ceramic composites.

Article PDF

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

References

Di Carlo JA, Yun HM, Morscher GN, et al. SiC/SiC composites for 1200 °C and above. In Handbook of Ceramic Composites. Boston, MA, USA: Springer US, 2005: 77–98.

Zok FW. Ceramic-matrix composites enable revolutionary gains in turbine engine efficiency. Am Ceram Soc Bull 2016, 95: 22–28.

Naslain R. Materials design and processing of high temperature ceramic matrix composites: State of the art and future trends. Adv Compos Mater 1999, 8: 3–16.

Naslain R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos Sci Technol 2004, 64: 155–170.

Steibel J. Ceramic matrix composites taking flight at GE Aviation. Am Ceram Soc Bull 2019, 98: 30–33.

Carrère N, Martin E, Lamon J. The influence of the interphase and associated interfaces on the deflection of matrix cracks in ceramic matrix composites. Compos A: Appl Sci Manuf 2000, 31: 1179–1190.

Naslain RR. The design of the fibre-matrix interfacial zone in ceramic matrix composites. Compos A: Appl Sci Manuf 1998, 29: 1145–1155.

Yang B, Zhou XG, Chai YX. Mechanical properties of SiCf/SiC composites with PyC and the BN interface. Ceram Int 2015, 41: 7185–7190.

Kerans RJ, Hay RS, Parthasarathy TA, et al. Interface design for oxidation-resistant ceramic composites. J Am Ceram Soc 2002, 85: 2599–2632.

Yu HJ, Zhou XG, Zhang W, et al. Mechanical properties of 3D KD-I SiCf/SiC composites with engineered fibre-matrix interfaces. Compos Sci Technol 2011, 71: 699–704.

Mei H, Bai QL, Sun YY, et al. The effect of heat treatment on the strength and toughness of carbon fiber/silicon carbide composites with different pyrolytic carbon interphase thicknesses. Carbon 2013, 57: 288–297.

Nakazato N, Kishimoto H, Park JS. Appropriate thickness of pyrolytic carbon coating on SiC fiber reinforcement to secure reasonable quasi-ductility on NITE SiC/SiC composites. Ceram Int 2018, 44: 19307–19313.

Cao XY, Yin XW, Fan XM, et al. Effect of PyC interphase thickness on mechanical behaviors of SiBC matrix modified C/SiC composites fabricated by reactive melt infiltration. Carbon 2014, 77: 886–895.

Mei H, Li HQ, Bai QL, et al. Increasing the strength and toughness of a carbon fiber/silicon carbide composite by heat treatment. Carbon 2013, 54: 42–47.

Buet E, Sauder C, Sornin D, et al. Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres. J Eur Ceram Soc 2014, 34: 179–188.

Rebillat F, Lamon J, Naslain R, et al. Properties of multilayered interphases in SiC/SiC chemical-vapor-infiltrated composites with “weak” and “strong” interfaces. J Am Ceram Soc 1998, 81: 2315–2326.

Yang W, Kohyama A, Katoh Y, et al. Effect of carbon and silicon carbide/carbon interlayers on the mechanical behavior of tyranno-SA-fiber-reinforced silicon carbide-matrix composites. J Am Ceram Soc 2003, 86: 851–856.

Mainzer B, Jemmali R, Watermeyer P, et al. Development of damage-tolerant ceramic matrix composites (SiC/SiC) using Si-BN/SiC/PyC fiber coatings and LSI processing. J Ceram Sci Tech 2017, 8:113–120.

Niu XX, Zhang HQ, Pei ZL, et al. Measurement of interfacial residual stress in SiC fiber reinforced Ni-Cr-Al alloy composites by Raman spectroscopy. J Mater Sci Technol 2019, 35: 88–93.

Xing YM, Tanaka Y, Kishimoto S, et al. Determining interfacial thermal residual stress in SiC/Ti-15-3 composites. Scripta Mater 2003, 48: 701–706.

Chen H, Zeng FH, Li WJ, et al. Effect of interfacial residual thermal stress on the fracture behavior of Cf/B4C composites prepared by spark plasma sintering. Ceram Int 2020, 46: 4587–4594.

Hsueh CH. Evaluation of interfacial shear strength, residual clamping stress and coefficient of friction for fiber-reinforced ceramic composites. Acta Metall Mater 1990, 38: 403–409.

Kollins K, Przybyla C, Amer MS. Residual stress measurements in melt infiltrated SiC/SiC ceramic matrix composites using Raman spectroscopy. J Eur Ceram Soc 2018, 38: 2784–2791.

Knauf MW, Przybyla CP, Ritchey AJ, et al. Residual stress determination of silicon containing boron dopants in ceramic matrix composites. J Am Ceram Soc 2019, 102: 2820–2829.

Amer MS. Raman Spectroscopy, Fullerenes, and Nanotechnology. Cambridge, UK: Royal Society of Chemistry, 2010.

Gouadec G, Karlin S, Wu J, et al. Physical chemistry and mechanical imaging of ceramic-fibre-reinforced ceramicor metal-matrix composites. Compos Sci Technol 2001, 61: 383–388.

Chawla KK. Processing of ceramic matrix composites. In Ceramic Matrix Composites. Boston, USA: Springer US, 2003: 107–138.

Jannotti P, Subhash G, Zheng J, et al. Measurement of microscale residual stresses in multi-phase ceramic composites using Raman spectroscopy. Acta Mater 2017, 129: 482–491.

Paszkowicz W, Pelka JB, Knapp M, et al. Lattice parameters and anisotropic thermal expansion of hexagonal boron nitride in the 10–297.5 K temperature range. Appl Phys A 2002, 75: 431–435.

Lipp A, Schwetz KA, Hunold K. Hexagonal boron nitride: Fabrication, properties and applications. J Eur Ceram Soc 1989, 5: 3–9.

Bochko AV, Zaporozhets OI. Elastic constants and elasticity moduli of cubic and wurtzitic boron nitride. Powder Metall Met Ceram 1996, 34: 417–423.

Pailler F, Lamon J. Micromechanics based model of fatigue/oxidation for ceramic matrix composites. Compos Sci Technol 2005, 65: 369–374.

Guillaumat L, Lamon J. Probabilistic-statistical simulation of the non-linear mechanical behavior of a woven SiCSiC composite. Compos Sci Technol 1996, 56: 803–808.

Ahmad AU, Liang HW, Ali S, et al. Cheap, reliable, reusable, thermally and chemically stable fluorinated hexagonal boron nitride nanosheets coated Au nanoparticles substrate for surface enhanced Raman spectroscopy. Sens Actuat B: Chem 2020, 304: 127394.

Du M, Li XL, Wang AZ, et al. One-step exfoliation and fluorination of boron nitride nanosheets and a study of their magnetic properties. Angewandte Chemie Int Ed 2014, 53: 3645–3649.

Fahy S. Erratum: Calculation of the strain-induced shifts in the infrared-absorption peaks of cubic boron nitride. Phys Rev B 1996, 53: 11884.

Sanjurjo JA, López-Cruz E, Vogl P, et al. Dependence on volume of the phonon frequencies and the ir effective charges of several III–V semiconductors. Phys Rev B 1983, 28: 4579–4584.

Erasmus RM, Comins JD, Fish ML, et al. Raman spectroscopy as a technique to characterize stress in diamond and cubic boron nitride. AIP Conf Proc 2000, 509: 1637–1644.

Acknowledgements

Authors appreciate the financial support of the research grant from the National Natural Science Foundation of China (No. 51902328), the research grant from the Science and Technology Commission of Shanghai Municipality (No. 19ZR1464700), the research grant from the Innovation Academy for Light-duty Gas Turbine, CAS (No. CXYJJ20-QN-09), the research grant from the Chinese Academy of Sciences (No. QYZDY-SSW-JSC031), and the research grant from the Key Deployment Projects of the Chinese Academy of Sciences (No. ZDRW-CN-2019-01).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, X., Cheng, G., Yang, J. et al. Effects of interfacial residual stress on mechanical behavior of SiCf/SiC composites. J Adv Ceram 11, 94–104 (2022). https://doi.org/10.1007/s40145-021-0519-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-021-0519-5