Abstract

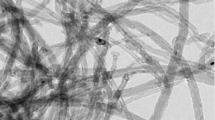

A nano-laminated Y3Si2C2 ceramic material was successfully synthesized via an in situ reaction between YH2 and SiC using spark plasma sintering technology. A MAX phase-like ternary layered structure of Y3Si2C2 was observed at the atomic-scale by high resolution transmission electron microscopy. The lattice parameters calculated from both X-ray diffraction and selected area electron diffraction patterns are in good agreement with the reported theoretical results. The nano-laminated fracture of kink boundaries, delamination, and slipping were observed at the tip of the Vickers indents. The elastic modulus and Vickers hardness of Y3Si2C2 ceramics (with 5.5 wt% Y2O3) sintered at 1500 °C were 156 and 6.4 GPa, respectively. The corresponding values of thermal and electrical conductivity were 13.7 W·m-1·K-1 and 6.3×105 S·m-1, respectively.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Gerdes MH, Witte AM, Jeitschko W, et al. Magnetic and electrical properties of a new series of rare earth silicide carbides with the composition R3Si2C2 (R=Y, La-nd, sm, Gd-Tm). J Solid State Chem 1998, 138: 201–206.

Jeitschko W, Gerdes MH, Witte AM, et al. Subcell structure and two different superstructures of the rare earth metal silicide carbides Y3Si2C2, Pr3Si2C2, Tb3Si2C2, and Dy3Si2C2. J Solid State Chem 2001, 156: 1–9.

Zhou YC, Xiang HM, Dai FZ. Y5Si3C and Y3Si2C2: Theoretically predicted MAX phase like damage tolerant ceramics and promising interphase materials for SiCf/SiC composites. J Mater Sci Technol 2019, 35: 313–322.

Barsoum MW. The MN+1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog Solid State Chem 2000, 28: 201–281.

Zhang H, Hu T, Wang XH, et al. Structural defects in MAX phases and their derivative MXenes: A look forward. J Mater Sci Technol 2020, 38: 205–220.

Xu Q, Zhou YC, Zhang HM, et al. Theoretical prediction, synthesis, and crystal structure determination of new MAX phase compound V2SnC. J Adv Ceram 2020, 9: 481–492.

Zhang H, Wang XH, Wan P, et al. Insights into hightemperature uniaxial compression deformation behavior of Ti3AlC2. J Am Ceram Soc 2015, 98: 3332–3337.

Xu K, Zou HK, Chang KK, et al. Thermodynamic description of the sintering aid system in silicon carbide ceramics with the addition of yttrium. J Eur Ceram Soc 2019, 39: 4510–4519.

Shao JQ, Li M, Chang KK, et al. Fabrication and characterization of SPS sintered SiC-based ceramic from Y3Si2C2-coated SiC powders. J Eur Ceram Soc 2018, 38: 4833–4841.

Liu JW, Zhou XB, Tatarko P, et al. Fabrication, microstructure, and properties of SiC/Al4SiC4 multiphase ceramics via an in situ formed liquid phase sintering. J Adv Ceram 2020, 9: 193–203.

Zhou XB, Liu JW, Zou SR, et al. Almost seamless joining of SiC using an in situ reaction transition phase of Y3Si2C2. J Eur Ceram Soc 2020, 40: 259–266.

Chen H, Zhao B, Zhao ZF, et al. Achieving strong microwave absorption capability and wide absorption bandwidth through a combination of high entropy rare earth silicide carbides/rare earth oxides. J Mater Sci Technol 2020, 47: 216–222.

Hrubovčáková M, Múdra E, Bureš R, et al. Microstructure, fracture behaviour and mechanical properties of conductive alumina based composites manufactured by SPS from graphenated Al2O3 powders. J Eur Ceram Soc 2020, 40: 4818–4824.

Ehsani M, Zakeri M, Razavi M. The effect of temperature on the physical and mechanical properties of nanostructured boron nitride by spark plasma sintering. J Alloys Compd 2020, 835: 155317.

Jiang RR, Li M, Yao YR, et al. Application of BIB polishing technology in cross-section preparation of porous, layered and powder materials: A review. Front Mater Sci 2019, 13: 107–125.

Volz E, Roosen A, Hartung W, et al. Electrical and thermal conductivity of liquid phase sintered SiC. J Eur Ceram Soc 2001, 21: 2089–2093.

Song WJ, Liu J, Dong HP, et al. Microstructural evolution and hydrogen storage proprieties of melt-spun eutectic Mg76.87Ni12.78Y10.35 alloy with low hydrides formation/decomposition enthalpy. Int J Hydrog Energy 2020, 45: 16644–16653.

Zou J, Zhang GJ, Fu ZY. In-situ ZrB2-hBN ceramics with high strength and low elasticity. J Mater Sci Technol 2020, 48: 186–193.

Munir ZA, Quach DV, Ohyanagi M. Electric current activation of sintering: A review of the pulsed electric current sintering process. J Am Ceram Soc 2011, 94: 1–19.

Lapauw T, Halim J, Lu J, et al. Synthesis of the novel Zr3AlC2 MAX phase. J Eur Ceram Soc 2016, 36: 943–947.

Zhang L, Feng J, Pan W. Vacuum sintering of transparent Cr:Y2O3 ceramics. Ceram Int 2015, 41: 8755–8760.

Ahmadi B, Reza SR, Ahsanzadeh-Vadeqani M, et al. Mechanical and optical properties of spark plasma sintered transparent Y2O3 ceramics. Ceram Int 2016, 42: 17081–17088.

Yeheskel O, Tevet O. Elastic moduli of transparent yttria. J Am Ceram Soc 1999, 82: 136–144.

Zhou XB, Jing L, Kwon YD, et al. Fabrication of SiCw/Ti3SiC2 composites with improved thermal conductivity and mechanical properties using spark plasma sintering. J Adv Ceram 2020, 9: 462–470.

Zhao GR, Chen JX, Li YM, et al. In situ synthesis, structure, and properties of bulk nanolaminate YAl3C3 ceramic. J Eur Ceram Soc 2017, 37: 83–89.

Tzenov NV, Barsoum MW. Synthesis and characterization of Ti3AlC2. J Am Ceram Soc 2004, 83: 825–832.

Tatarko P, Chlup Z, Mahajan A, et al. High temperature properties of the monolithic CVD β-SiC materials joined with a pre-sintered MAX phase Ti3SiC2 interlayer via solid-state diffusion bonding. J Eur Ceram Soc 2017, 37: 1205–1216.

Yi Q, Zhou SM, Teng H, et al. Structural and optical properties of Tm:Y2O3 transparent ceramic with La2O3, ZrO2 as composite sintering aid. J Eur Ceram Soc 2012, 32: 381–388.

Acknowledgements

We would like to appreciate the support from the Ningbo 3315 Innovative Teams Program, China (Grant No. 2019A-14-C). This study was supported by the National Natural Science Foundation of China (Grant Nos. 11975296 and 51811540402).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shi, LK., Zhou, X., Dai, JQ. et al. Microstructure and properties of nano-laminated Y3Si2C2 ceramics fabricated via in situ reaction by spark plasma sintering. J Adv Ceram 10, 578–586 (2021). https://doi.org/10.1007/s40145-021-0459-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-021-0459-0