Abstract

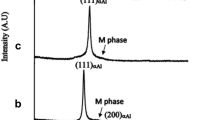

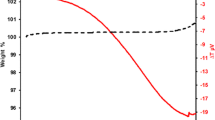

Ceramic-metallic MAX phase of chromium aluminium carbide ternary compounds was successfully obtained through deposition by DC sputtering onto Si substrates. A study of the influence of substrate temperature and in-air post-annealing on the film crystallinity and oxidation was undertaken. Scanning electron microscopy (SEM), wavelength-dispersive X-ray analysis (WDSX), and X-ray diffraction (XRD) were used for film characterization. It is shown that, at substrate temperature of about 450 °C, as-deposited films are amorphous with small nanocrystals. Subsequent annealing in air at 700 °C leads to film crystallization and partial oxidation. WDSX spectroscopy shows that the films oxidise to a depth of around 120 nm, or 5% of total film thickness which amounts at around 2.68 μm. As a novelty, this demonstrates the possibility of in-air crystallization of Cr2AlC films without significant oxidation. Materials Analysis Using Diffraction (MAUD) software package for a full-profile analysis of the XRD patterns (Rietveld-type) was used to determine that, as a result of annealing, the average crystallite size changes from 7 to 34 nm, while microstrain decreases from 0.79% to 0.24%. A slight tendency of preferential growth along the (10ī0) direction has been observed. Such texturing of the microstructure has the potential of inducing beneficial anisotropic fracture behaviour in the coatings, potentially interesting for several industrial applications in load-bearing devices.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Jeitschko W, Nowotny H, Benesovsky F. Kohlenstoffhaltige ternäre Verbindungen (H-phase). Monatshefte für Chemie 1963, 94: 672–676.

Barsoum MW, El-Raghy T. The MAX phases: Unique new carbide and nitride materials: Ternary ceramics turn out to be surprisingly soft and machinable, yet also heat-tolerant, strong and lightweight. Amer Sci 2001, 89: 334–343.

Eklund P, Beckers M, Jansson U, et al. The Mn+1AXn phases: Materials science and thin-film processing. Thin Solid Films 2010, 518: 1851–1878.

Wang J, Zhou Y. Recent progress in theoretical prediction, preparation, and characterization of layered ternary transition-metal carbides. Annu Rev Mater Res 2009, 39: 415–443.

Lin ZJ, Zhou YC, Li MS. Synthesis, microstructure, and property of Cr2AlC. J Mater Sci Technol 2007, 23: 721–746.

Schneider JM, Sun Z, Mertens R, et al. Ab initio calculations and experimental determination of the structure of Cr2AlC. Solid State Commun 2004, 130: 445–449.

Mertens R, Sun Z, Music D, et al. Effect of the composition on the structure of Cr–Al–C investigated by combinatorial thin film synthesis and ab initio calculations. Adv Eng Mater 2004, 6: 903–907.

Walter C, Sigumonrong DP, El-Raghy T, et al. Towards large area deposition of Cr2AlC on steel. Thin Solid Films 2006, 515: 389–393.

Shtansky DV, Kiryukhantsev-Korneev PV, Sheveyko AN, et al. Comparative investigation of TiAlC(N), TiCrAlC(N), and CrAlC(N) coatings deposited by sputtering of МАХ-phase Ti2-xCr x AlC targets. Surf Coat Technol 2009, 203: 3595–3609.

Berger O, Leyens C, Heinze S, et al. Characterization of Cr–Al–C and Cr–Al–C–Y films synthesized by high power impulse magnetron sputtering at a low deposition temperature. Thin Solid Films 2015, 580: 6–11.

Naveed M, Obrosov A, Zak A, et al. Sputtering power effects on growth and mechanical properties of Cr2AlC MAX phase coatings. Metals 2016, 6: 265.

Obrosov A, Gulyaev R, Zak A, et al. Chemical and morphological characterization of magnetron sputtered at different bias voltages Cr–Al–C coatings. Materials 2017, 10: 156.

Smialek JL, Nesbitt JA, Gabb TP, et al. Hot corrosion and low cycle fatigue of a Cr2AlC-coated superalloy. Mat Sci Eng A 2018, 711: 119–129.

Smialek JL. Oxidation of Al2O3 scale-forming MAX Phases in turbine environments. Metall Mater Trans A 2018, 49: 782–792.

Li Y, Qian Y, Zhao G, et al. Preparation of Nb2AlC coating by DC magnetron sputtering and subsequent annealing. Ceram Int 2017, 43: 6622–6625.

Su R, Zhang H, O’Connor DJ, et al. Deposition and characterization of Ti2AlC MAX phase and Ti3AlC thin films by magnetron sputtering. Mater Lett 2016, 179: 194–197.

Li Y, Zhao G, Qian Y, et al. Deposition of phase-pure Cr2AlC coating by DC magnetron sputtering and post annealing using Cr–Al–C targets with controlled elemental composition but different phase compositions. J Mater Sci Technol 2017, https://doi.org/10.1016/j.jmst.2017.01.029.

Su R, Zhang H, Meng X, et al. Synthesis of Cr2AlC thin films by reactive magnetron sputtering. Fusion Eng Des 2017, 125: 562–566

Chen YT, Music D, Shang L, et al. Nanometre-scale 3D defects in Cr2AlC thin films. Sci Rep 2017, 7: 984.

Duan X, Shen L, Jia D, et al. Synthesis of high-purity, isotropic or textured Cr2AlC bulk ceramics by spark plasma sintering of pressure-less sintered powders. J Eur Ceram Soc 2015, 35: 1393–1400.

Li JJ, Hu LF, Li FZ, et al. Variation of microstructure and composition of the Cr2AlC coating prepared by sputtering at 370 and 500 °C. Surf Coat Technol 2010, 204: 3838–3845.

Wang QM, Renteria AF, Schroeter O, et al. Fabrication and oxidation behavior of Cr2AlC coating on Ti6242 alloy. Surf Coat Technol 2010, 204: 2343–2352.

Crisan O, von Haeften K, Ellis AM, et al. Structure and magnetic properties of Fe/Fe oxide clusters. J Nanopart Res 2008, 10: 193–199.

Crisan O, Grenèche JM, Le Breton JM. Magnetism of nanocrystalline finemet alloy: Experiment and simulation. Eur Phys J B 2003, 34: 155–162.

Crisan O, Le Breton JM, Noguès M, et al. Magnetism and phase structure of crystallized Sm–Fe–B melt spun ribbons. J Phys: Condens Matter 2002, 14: 12599–12609.

Crisan O, Labaye Y, Berger L, et al. Exchange coupling effects in nanocrystalline alloys studied by Monte Carlo simulation. J Appl Phys 2002, 91: 8727–8729.

Seqqat M, Nogues M, Crisan O, et al. Magnetic properties of Fe100-xSm x thin films and Fe80-xSm x B20 thin films and ribbons. J Magn Magn Mater 1996, 157–158: 225–226.

Crisan O, Crisan AD, Randrianantoandro N, et al. Crystallization processes and phase evolution in amorphous Fe–Pt–Nb–B alloys. J Alloys Compd 2007, 440: L3–L7.

Abdulkadhim A, to Baben M, Takahashi T, et al. Crystallization kinetics of amorphous Cr2AlC thin films. Surf Coat Technol 2011, 206: 599–603.

Matthies S, Lutterotti L, Wenk HR, et al. Advances in texture analysis from diffraction spectra. J Appl Cryst 1997, 30: 31–42.

Syassen K. Datlab, version 1.38 XP. MPI/FKF Stuttgart, Germany, 2005.

Bicerano J, Adler D. Theory of the structures of non-crystalline solids. Pure Appl Chem 1987, 59: 101–144.

Klung HP, Alexander LE. X-ray Diffraction Procedures, 2nd edn. New York: Wiley, 1974.

Balzar D, Ledbetter H. Voigt-function modeling in Fourier analysis of size- and strain-broadened X-ray diffraction peaks. J Appl Cryst 1993, 26: 97–103.

Balzar D. X-ray diffraction line broadening: Modeling and applications to high-Tc superconductors. J Res Natl Inst Stand Technol 1993, 98: 321.

Warren BE. X-ray Diffraction. Reading, MA, USA: Addison Wesley, 1969.

Crisan O, Le Breton JM, Maignan A, et al. Structural refinement effect on the magnetoresistive properties of annealed melt spun Cu–Co–(Fe–Si) ribbons. J Magn Magn Mater 1999, 195: 428–436.

Kajikawa J. Texture development of non-epitaxial polycrystalline ZnO films. J Cryst Growth 2006, 289: 387–394.

Lee DN. Textures and structures of vapor deposits. J Mater Sci 1999, 34: 2575–2582.

Acknowledgements

Financial support from Romanian Ministry of Research and Innovation from project PN-III-P4-ID-PCE-2016-0833 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Crisan, O., Crisan, A.D. Incipient low-temperature formation of MAX phase in Cr–Al–C films. J Adv Ceram 7, 143–151 (2018). https://doi.org/10.1007/s40145-018-0265-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-018-0265-5