Abstract

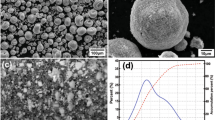

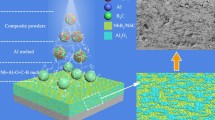

ZrB2–ZrC–SiC ternary coatings on C/C composites are investigated by reactive melt infiltration of ZrSi2 alloy into pre-coatings. Two different pre-coating structures, including porous B4C–C and dense C/B, are designed by slurry dip and chemical vapor deposition (CVD) process respectively. The coating prepared by reactive melt infiltration (RMI) into B4C–C presents a flat and smooth surface with a three-layer cross-sectional structure, namely interior SiC transition layer, gradient ZrB2–ZrC–SiC layer, and ZrB2–ZrC exterior layer. In comparison, the coating prepared by RMI into C/B shows a more granular surface with a different three-layer cross-sectional structure, interior unreacted B–C pre-coating layer, middle SiC layer, and exterior ZrB2–ZrC–ZrSi2 layer. The forming mechanisms of the specific microstructures in two coatings are also investigated and discussed in detail.

Article PDF

Similar content being viewed by others

References

Savage G. Carbon–Carbon Composites. London: Chapman & Hall, 1993.

Dhami TL, Bahl OP, Awasthy BR. Oxidation-resistant carbon–carbon composites up to 1700°C. Carbon 1995, 33: 479–490.

Joshi A, Lee JS. Coatings with particulate dispersions for high temperature oxidation protection of carbon and C/C composites. Composites Part A 1997, 28: 181–189.

Alvey MD, George PM. ZrPt3 as a high-temperature, reflective, oxidation-resistant coating for carbon–carbon composites. Carbon 1991, 29: 523–530.

Zhou H-J, Feng Q, Kan Y-M, et al. ZrB2–SiC coatings prepared by vapor and liquid silicon infiltration methods: Microstructure and oxidation resistance property. J Inorg Mater 2013, 28: 1158–1162. (in Chinese)

Rezaie A, Fahrenholtz WG, Hilmas GE. The effect of a graphite addition on oxidation of ZrB2–SiC in air at 1500 °C. J Eur Ceram Soc 2013, 33: 413–421.

Williams PA, Sakidja R, Perepezko JH, et al. Oxidation of ZrB2–SiC ultra-high temperature composites over a wide range of SiC content. J Eur Ceram Soc 2012, 32: 3875–3883.

Einset EO. Analysis of reactive melt infiltration in the processing of ceramics and ceramic composites. Chem Eng Sci 1998, 53: 1027–1039.

Chen X, Dong S, Kan Y, et al. 3D Cf/SiC–ZrC–ZrB2 composites fabricated via sol–gel process combined with reactive melt infiltration. J Eur Ceram Soc 2016, 36: 3607–3613.

Pi H, Fan S, Wang Y. C/SiC–ZrB2–ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy. Ceram Int 2012, 38: 6541–6548.

Hu C, Niu Y, Huang S, et al. In-situ fabrication of ZrB2–SiC/SiC gradient coating on C/C composites. J Alloys Compd 2015, 646: 916–923.

Jia Y, Li H, Li L, et al. Effect of monolithic LaB6 on the ablation resistance of ZrC/SiC coating prepared by supersonic plasma spraying for C/C composites. J Mater Sci Technol 2016, 32: 996–1002.

Abdollahi A, Ehsani N, Valefi Z. Thermal shock resistance and isothermal oxidation behavior of C/SiC–SiCnano functionally gradient coating on graphite produced via reactive melt infiltration (RMI). Mater Chem Phys 2016, 182: 49–61.

Zhou H, Gao L, Wang Z, et al. ZrB2–SiC oxidation protective coating on C/C composites prepared by vapor silicon infiltration process. J Am Ceram Soc 2010, 93: 915–919.

Zhang Y, Hu H, Zhang P, et al. SiC/ZrB2–SiC–ZrC multilayer coating for carbon/carbon composites against ablation. Surf Coat Technol 2016, 300: 1–9.

Qi Y-S, Wang Y-Y, Zhou C-L, et al. On the ZrB2–SiC/SiC ultrahigh temperature ceramics coating for Cf/SiC composition. Adv Ceram 2016, 37: 119–125. (in Chinese)

Zou L, Wali N, Yang J-M, et al. Microstructural development of a Cf/ZrC composite manufactured by reactive melt infiltration. J Eur Ceram Soc 2010, 30: 1527–1535.

Hillig WB. Melt infiltration approach to ceramic matrix composites. J Am Ceram Soc 1988, 71: C-96–C-99.

Zhu Y, Wang S, Li W, et al. Preparation of carbon fiber-reinforced zirconium carbide matrix composites by reactive melt infiltration at relative low temperature. Scripta Mater 2012, 67: 822–825.

Chen X, Dong S, Kan Y, et al. 3D Cf/SiC–ZrC–ZrB2 composites fabricated via sol–gel process combined with reactive melt infiltration. J Eur Ceram Soc 2016, 36: 3607–3613.

Li Z, Li H, Zhang S, et al. Microstructure and ablation behaviors of integer felt reinforced C/C–SiC–ZrC composites prepared by a two-step method. Ceram Int 2012, 38: 3419–3425.

Pi H, Fan S, Wang Y. C/SiC–ZrB2–ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy. Ceram Int 2012, 38: 6541–6548.

Zeng B, Feng Z, Li S, et al. Microstructure and deposition mechanism of CVD amorphous boron carbide coatings deposited on SiC substrates at low temperature. Ceram Int 2009, 35: 1877–1882.

Li S, Zeng B, Feng Z, et al. Effects of heat treatment on the microstructure of amorphous boron carbide coating deposited on graphite substrates by chemical vapor deposition. Thin Solid Films 2010, 519: 251–258.

Berjonneau J, Chollon G, Langlais F. Deposition process of amorphous boron carbide from CH4/BCl3/H2 precursor. J Electrochem Soc 2006, 153: C795–C800.

Tong Y, Bai S, Chen K. C/C–ZrC composite prepared by chemical vapor infiltration combined with alloyed reactive melt infiltration. Ceram Int 2012, 38: 5723–5730.

Halverson DC, Pyzik AJ, Aksay IA. Boron–carbide–aluminum and boron–carbide–reactive metal cermets. U.S. Patent 4,605,440. 1986.

Acknowledgements

The authors are grateful to the financial support from the National Key Research and Development Program of China (No. 2017YFB0703200), and the research grant from Science and Technology Commission of Shanghai Municipality (No. 16DZ2260600).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/y/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Xue, C., Zhou, H., Hu, J. et al. Fabrication and microstructure of ZrB2–ZrC–SiC coatings on C/C composites by reactive melt infiltration using ZrSi2 alloy. J Adv Ceram 7, 64–71 (2018). https://doi.org/10.1007/s40145-017-0257-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-017-0257-x