Abstract

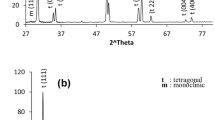

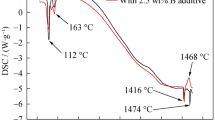

This paper presents the experiments on the synthesis of zirconium carbide (ZrC) using carbothermal reduction of zirconia (ZrO2). The ratio of ZrO2:C is used to adapt ZrC x O y with x < 1 or ZrC + C. The modification of ZrC x O y and the total carbon amount allows the use of pressureless sintering method in combination with sintering temperatures ≤ 2000 °C. Fully densified ZrC products are obtained. The relevant details of ZrC formation are investigated by X-ray diffraction (XRD). The sintered products are characterized by XRD, field emission scanning electron microscopy (FESEM), as well as mechanical and electrical methods. XRD and FESEM investigations show that ZrC x O y is formed during the manufacturing process. The grain size and additional zirconia or carbon are related to the ZrO2:C ratio of the starting powder mixture. Bending strength up to 300 MPa, Young’s modulus up to 400 GPa, fracture toughness up to 4.1 MPa·m1/2, and electrical resistance at room temperature around 10−4 Ω·cm are reached by the pressureless sintered ZrC.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Barnier P, Brodhag C, Thevenot F. Hot-pressing kinetics of zirconium carbide. J Mater Sci 1986, 21: 2547–2552.

Chakrabarti T, Rangaraj L, Jayaram V. Effect of zirconium on the densification of reactively hot-pressed zirconium carbide. J Am Ceram Soc 2014, 97: 3092–3102.

Landwehr SE, Hilmas GE, Fahrenholtz WG, et al. Microstructure and mechanical characterization of ZrC–Mo cermets produced by hot isostatic pressing. Mat Sci Eng A 2008, 497: 79–86.

Nachiappan C, Rangaraj L, Divakar C, et al. Synthesis and densification of monolithic zirconium carbide by reactive hot pressing. J Am Ceram Soc 2010, 93: 1341–1346.

Wang X-G, Guo W-M, Kan Y-M, et al. Densification behavior and properties of hot-pressed ZrC ceramics with Zr and graphite additives. J Eur Ceram Soc 2011, 31: 1103–1111.

Wang Y, Chen L, Zhang T, et al. Effect of iron additive on the sintering behavior of hot-pressed ZrC–W composites. Key Eng Mater 2008, 368–372: 1764–1766.

Rangaraj L, Divakar C, Jayaram V. Reactive hot pressing of ZrB2–ZrC x ultra-high temperature ceramic composites with the addition of SiC particulate. J Eur Ceram Soc 2010, 30: 3263–3266.

Medri V, Monteverde F, Balbo A, et al. Comparison of ZrB2–ZrC–SiC composites fabricated by spark plasma sintering and hot-pressing. Adv Eng Mater 2005, 7: 159–163.

Zhao L, Jia D, Wang Y, Rao J, et al. ZrC–ZrB2 matrix composites with enhanced toughness prepared by reactive hot pressing. Scripta Mater 2010, 63: 887–890.

Zimmermann JW, Hilmas GE, Fahrenholtz WG, et al. Fabrication and properties of reactively hot pressed ZrB2–SiC ceramics. J Eur Ceram Soc 2007, 27: 2729–2736.

Antou G, Gendre M, Laborde E, et al. High temperature compressive creep of spark plasma sintered zirconium (oxy-)carbide. Mat Sci Eng A 2014, 612: 326–334.

Gendre M, Maître A, Trolliard G. A study of the densification mechanisms during spark plasma sintering of zirconium (oxy-)carbide powders. Acta Mater 2010, 58: 2598–2609.

Gendre M, Maître A, Trolliard G. Synthesis of zirconium oxycarbide (ZrC x O y ) powders. Influence of stoichiometry on densification kinetics during spark plasma sintering and on mechanical properties. J Eur Ceram Soc 2011, 31: 2377–2385.

Silvestroni L, Sciti D. Microstruture and properties of pressureless sintered ZrC-based materials. J Mater Res 2008, 23: 1882–1889.

Zhao L, Jia D, Duan X, et al. Pressureless sintering of ZrC-based ceramics by enhancing powder sinterability. Int J Refract Met H 2011, 29: 516–521.

Sciti D, Silvestroni L, Nygren M. Spark plasma sintering of Zr- and Hf-borides with decreasing amounts of MoSi2 as sintering aid. J Eur Ceram Soc 2008, 28: 1287–1296.

Sun S-K, Zhang G-J, Wu W-W, et al. Reactive spark plasma sintering of ZrC and HfC ceramics with fine microstructures. Scripta Mater 2013, 69: 139–142.

Maitre A, Lefort P. Solid state reaction of zirconia with carbon. Solid State Ionics 1997, 104: 109–122.

Xie J, Fu Z, Wang Y, et al. Synthesis of nanosized zirconium carbide powders by a combinational method of sol–gel and pulse current heating. J Eur Ceram Soc 2014, 34: 13.e1–13.e7.

Núñez-González B, Ortiz AL, Guiberteau F, et al. Improvement of the spark-plasma-sintering kinetics of ZrC by high-energy ball-milling. J Am Ceram Soc 2012, 95: 453–456.

Kim J-H, Seo M, Park C, et al. Effect of two-step reduction on ZrC size and dispersion. J Alloys Compd 2015, 633: 5–10.

Sara RV. The system zirconium–carbon. J Am Ceram Soc 1965, 48: 243–247.

Katoh Y, Vasudevamurthy G, Nozawa T, et al. Properties of zirconium carbide for nuclear fuel applications. J Nucl Mater 2013, 441: 718–742.

Kempter CP, Fries JR. Crystallographic data 189: Zirconium carbide. Anal Chem 1960, 32: 570.

Cheng D, Wang, S, Ye H. First-principles calculations of the elastic properties of ZrC and ZrN. J Alloys Compd 2004, 377: 221–224.

Riedel R. Handbook of Ceramic Hard Materials. WILEY-VCH Verlag GmbH, 2000.

Sagdic S, Goller G. Densification behavior and mechanical properties of spark plasma sintered ZrC–SiC and ZrC–SiC–CNT composites. J Aus Ceram Soc 2014, 50: 76–82.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Schönfeld, K., Martin, HP. & Michaelis, A. Pressureless sintering of ZrC with variable stoichiometry. J Adv Ceram 6, 165–175 (2017). https://doi.org/10.1007/s40145-017-0229-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-017-0229-1