Abstract

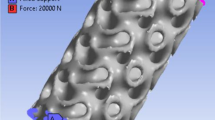

In this paper, novel Al2O3-based poly-hollow microsphere (PHM) ceramics were prepared using Si3N4 and Al2O3 PHMs as pore-forming agents. The effect of Si3N4 and Al2O3 PHMs with different percentages on properties of Al2O3-based PHM ceramics was investigated. Through adjusting percentage of Al2O3 PHMs, Al2O3-based PHM ceramics with enhanced properties are achieved. X-ray diffraction (XRD) results show that main phases of Al2O3-based PHM ceramics vary from β-SiAlON (z value increases from 2.9 to 4) to Al2O3 with the increase of percentage of Al2O3 PHMs from 10% to 100%. The different phase compositions result in different properties of Al2O3-based PHM ceramics. With the increase of percentage of Al2O3 PHMs, porosity of Al2O3-based PHM ceramics gradually decreases, while their shrinkage, flexural strength, and fracture toughness firstly decrease and then increase. Using different kinds of ceramic PHMs as pore-forming agents, various novel and high-performance porous ceramics could be prepared via optimizing percentage of ceramic PHMs in the future.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Xue W, Huang Y, Xie Z, et al. Al2O3 ceramics with well-oriented and hexagonally ordered pores: The formation of microstructures and the control of properties. J Eur Ceram Soc 2012, 32: 3151–3159.

Yan W, Lin X, Chen J, et al. Effect of TiO2 addition on microstructure and strength of porous spinel (MgAl2O4) ceramics prepared from magnesite and Al(OH)3. J Alloys Compd 2015, 618: 287–291.

Cui X, Tang S, Zhou H. Mesoporous alumina materials synthesized in different gel templates. Mater Lett 2013, 98: 116–119.

Dash SR, Sarkar R, Bhattacharyya S. Gel casting of hydroxyapatite with naphthalene as pore former. Ceram Int 2015, 41: 3775–3790.

Yin L, Zhou X, Yu J, et al. New consolidation process inspired from making steamed bread to prepare Si3N4 foams by protein foaming method. J Eur Ceram Soc 2013, 33: 1387–1392.

Yu J, Yang J, Li S, et al. Preparation of Si3N4 foam ceramics with nest-like cell structure by particle-stabilized foams. J Am Ceram Soc 2012, 95: 1229–1233.

Sciamanna V, Nait-Ali B, Gonon M. Mechanical properties and thermal conductivity of porous alumina ceramics obtained from particle stabilized foams. Ceram Int 2015, 41: 2599–2606.

Soh E, Kolos E, Ruys AJ. Foamed high porosity alumina for use as bone tissue scaffold. Ceram Int 2015, 41: 1031–1047.

Tang Y, Miao Q, Qiu S, et al. Novel freeze-casting fabrication of aligned lamellar porous alumina with a centrosymmetric structure. J Eur Ceram Soc 2014, 34: 4077–4082.

Li W, Lu K, Walz JY. Effects of solids loading on sintering and properties of freeze-cast kaolinite–silica porous composites. J Am Ceram Soc 2013, 96: 1763–1771.

Xia Y, Zeng YP, Jiang D. Microstructure and mechanical properties of porous Si3N4 ceramics prepared by freeze-casting. Mater Design 2012, 33: 98–103.

Zuo KH, Zeng Y-P, Jiang D. Properties of microstructurecontrollable porous yttria-stabilized ziroconia ceramics fabricated by freeze casting. Int J Appl Ceram Tec 2008, 5: 198–203.

Chen F, Yang Y, Shen Q, et al. Macro/micro structure dependence of mechanical strength of low temperature sintered silicon carbide ceramic foams. Ceram Int 2012, 38: 5223–5229.

Silva SA, Brunelli DD, Melo FCL, et al. Preparation of a reticulated ceramic using vegetal sponge as templating. Ceram Int 2009, 35: 1575–1579.

Delbrücke T, Gouvêa RA, Moreira ML, et al. Sintering of porous alumina obtained by biotemplate fibers for low thermal conductivity applications. J Eur Ceram Soc 2013, 33: 1087–1092.

Xu G, Ma Y, Cui H, et al. Preparation of porous millite–corundum ceramics with controlled pore size using bioactive yeast as pore-forming agent. Mater Lett 2014, 116: 349–352.

Nishijima H, Suzuki Y. Microstructural control of porous Al2TiO5 by using various starches as pore-forming agents. J Ceram Soc Jpn 2014, 122: 565–569.

Chen F, Shen Q, Yan F, et al. Pressureless sintering of α-Si3N4 porous ceramics using a H3PO4 pore-forming agent. J Am Ceram Soc 2007, 90: 2379–2383.

Su Z, Xi X, Hu Y, et al. A new Al2O3 porous ceramic prepared by addition of hollow spheres. J Porous Mater 2014, 21: 601–609.

Qi F, Xu X, Xu J, et al. A novel way to prepare hollow sphere ceramics. J Am Ceram Soc 2014, 97: 3341–3347.

Yang J-L, Xu X-X, Wu J-M, et al. Preparation of Al2O3 poly-hollow microsphere (PHM) ceramics using Al2O3 PHMs coated with sintering additive via co-precipitation method. J Eur Ceram Soc 2015, 35: 2593–2598.

Wu J-M, Zhang X-Y, Yang J-L. Novel porous Si3N4 ceramics prepared by aqueous gelcasting using Si3N4 poly-hollow microspheres as pore-forming agent. J Eur Ceram Soc 2014, 34: 1089–1096.

Wu J-M, Zhang X-Y, Wang Y-L, et al. Effect of sintering temperature on properties of porous Si3N4 ceramics with Si3N4 poly-hollow microspheres as pore-forming agent. J Chin Ceram Soc (Eng.) 2014, 1: 129–134.

Zhang X-Y, Wu J-M, Yang J-L. Pore morphology designs of porous Si3N4-based ceramics using Si3N4 and Al2O3 poly-hollow microspheres as pore-forming agents. Mater Lett 2015, 144: 39–42.

Xie ZP. Structural Ceramics. Beijing: Tsinghua University Press, 2011: 452.

Tanaka I, Nasu S, Adachi H, et al. Electronic structure behind the mechanical properties of β-SiAlONs. Acta Metall Mater 1992, 40: 1995–2001.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wu, JM., Chen, Y., Zhang, XY. et al. Phase evolution and properties of novel Al2O3-based poly-hollow microsphere (PHM) ceramics. J Adv Ceram 5, 176–182 (2016). https://doi.org/10.1007/s40145-016-0187-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-016-0187-z