Abstract

Most widely used piezoelectric ceramics are based on Pb(Zr,Ti)O3 (PZT) composition which has adverse environmental and health effects due to its high lead content. Environmental and safety concerns with respect to the utilization, recycling, and disposal of lead-based piezoelectric ceramics have induced a new surge in developing lead-free piezoelectric ceramics. Among all the lead-free ceramics, (K,Na)NbO3 (KNN) has drawn increasing attention because of its well-balanced piezoelectric properties and better environmental compatibility. On basis of the author’s work, this review summarizes the progress that has been made in recent years on development of KNN-based piezoelectric ceramics, including crystallographic structure and phase transition analysis, pressurized solid-state sintering as well as liquid-phase-assisted sintering process, and poling treatment for property enhancement. All in all, KNN is a promising lead-free system, but more research is still required both from academic and industrial interests.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Jaffe B, Cook WR, Jaffe H. Piezoelectric Ceramics. New York: Academic Press, 1971.

Eu-Directive 2002/96/Ec: Waste electrical and electronic equipment (WEEE). Off J Eur Union 2003, 46: 24–38.

Eu-Directive 2002/95/Ec: Restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS). Off J Eur Union 2003, 46: 19–23.

Saito Y, Takao H, Tani T, et al. Lead-free piezoceramics. Nature 2004, 432: 84–87.

Guo YP, Kakimoto K, Ohsato H. Phase transitional behavior and piezoelectric properties of (Na0.5K0.5)NbO3-LiNbO3 ceramics. Appl Phys Lett 2004, 85: 4121–4123.

Zhao P, Zhang BP, Li JF. High piezoelectric d33 coefficient in Li-modified lead-free (Na,K)NbO3 ceramics sintered at optimal temperature. Appl Phys Lett 2007, 90: 242909.

Hollenstein E, Davis M, Damjanovic D, et al. Piezoelectric properties of Li- and Ta-modified (K0.5Na0.5)NbO3 ceramics. Appl Phys Lett 2005, 87: 182905.

Matsubara M, Yamaguchi T, Kikuta K, et al. Effect of Li substitution on the piezoelectric properties of potassium sodium niobate ceramics. Jpn J Appl Phys 2005, 44: 6136–6142.

Du HL, Tang FS, Liu DJ, et al. The microstructure and ferroelectric properties of (K0.5Na0.5)NbO3-LiNbO3 lead-free piezoelectric ceramics. Mater Sci Eng B-Solid State Mater Adv Technol 2007, 136: 165–169.

Klein N, Hollenstein E, Damjanovic D, et al. A study of the phase diagram of (K,Na,Li)NbO3 determined by dielectric and piezoelectric measurements, and raman spectroscopy. J Appl Phys 2007, 102: 014112.

Song HC, Cho KH, Park HY, et al. Microstructure and piezoelectric properties of (1−x)(Na0.5K0.5)NbO3-xLiNbO3 ceramics. J Am Ceram Soc 2007, 90: 1812–1816.

Wang K, Li J F, Liu N. Piezoelectric properties of low-temperature sintered Li-modified (Na, K)NbO3 lead-free ceramics. Appl Phys Lett 2008, 93: 092904.

Guo YP, Kakimoto K, Ohsato H. (Na0.5K0.5)NbO3-LiTaO3 lead-free piezoelectric ceramics. Mater Lett 2005, 59: 241–244.

Zhao P, Zhang BP, Li JF. Enhancing piezoelectric d33 coefficient in Li/Ta-codoped lead-free (Na,K)NbO3 ceramics by compensating Na and K at a fixed ratio. Appl Phys Lett 2007, 91: 172901.

Dai YJ, Zhang XW, Zhou GY. Phase transitional behavior in K0.5Na0.5NbO3-LiTaO3 ceramics. Appl Phys Lett 2007, 90: 262903.

Kim MS, Jeong SJ, Song JS. Microstructures and piezoelectric properties in the Li2O-excess 0.95(Na0.5K0.5)NbO3-0.05LiTaO3 cramics. J Am Ceram Soc 2007, 90: 3338–3340.

Lin D, Kwok KW, Chan HLW. Microstructure, phase transition, and electrical properties of (K0.5Na0.5)1−xLix(Nb1−yTay)O3 lead-free piezoelectric ceramics. J Appl Phys 2007, 102: 034102.

Chang YF, Yang ZP, Ma DF, et al. Phase transitional behavior, microstructure, and electrical properties in Ta-modified [(K0.458Na0.542)0.96Li0.04]NbO3 lead-free piezoelectric ceramics. J Appl Phys 2008, 104: 024109.

Wu L, Zhang JL, Shao SF, et al. Phase coexistence and high piezoelectric properties in (K0.40Na0.60)0.96Li0.04Nb0.80Ta0.20O3 ceramics. J Phys D: Appl Phys 2008, 41: 035402.

Zuo RZ, Ye C, Fang XS, et al. Processing and piezoelectric poperties of (Na0.5K0.5)0.96Li0.04(Ta0.1Nb0.9)1−xCuxO3−3x/2 lead-free ceramics. J Am Ceram Soc 2008, 91: 914–917.

Zang GZ, Wang JF, Chen HC, et al. Perovskite (Na0.5K0.5)1−x(LiSb)xNb1−xO3 lead-free piezoceramics. Appl Phys Lett 2006, 88: 212908.

Zhang SJ, Xia R, Shrout TR, et al. Piezoelectric properties in provskite 0.948(K0.5Na0.5)NbO3-0.052LiSbO3 lead-free ceramics. J Appl Phys 2006, 100: 104108.

Wu JG, Xiao DQ, Wang YY, et al. Effects of K content on the dielectric, piezoelectric, and ferroelectric properties of 0.95(KxNa1−x)NbO3-0.05LiSbO3 lead-free ceramics. J Appl Phys 2008, 103: 024102.

Park HY, Ahn CW, Song HC, et al. Microstructure and piezoelectric poperties of 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 ceramics. Appl Phys Lett 2006, 89: 062906.

Lin D, Kwok KW, Chan HLW. Structure, dielectric, and piezoelectric properties of CuO-doped K0.5Na0.5NbO3-BaTiO3 lead-free ceramics. J Appl Phys 2007, 102: 074113.

Park HY, Cho KH, Paik DS, et al. Microstructure and piezoelectric properties of lead-free (1-x)(Na0.5K0.5)NbO3-xCaTiO3 ceramics. J Appl Phys 2007, 102: 124101.

Zhang SJ, Xia R, Shrout TR. Modified (K0.5Na0.5)NbO3 based lead-free piezoelectrics with broad temperature usage range. Appl Phys Lett 2007, 91: 132913.

Chang RC, Chu SY, Lin YF, et al. The effects of sintering temperature on the properties of (Na0.5K0.5)NbO3-CaTiO3 based lead-free ceramics. Sensor Actuat A-Phys 2007, 138: 355–360.

Chang RC, Chu SY, Lin YF, et al. An investigation of (Na0.5K0.5)NbO3-CaTiO3 based lead-free ceramics and surface acoustic wave devices. J Eur Ceram Soc 2007, 27: 4453–4460.

Wu JG, Xiao DQ, Wang YY, et al. Improved temperature stability of CaTiO3-modified [(K0.5Na0.5)0.96]Li0.04](Nb0.91Sb0.05Ta0.04)O3 lead-free piezoelectric ceramics. J Appl Phys 2008, 104: 024102.

Zuo RZ, Fang XS, Ye C. Phase structures and electrical properties of new lead-free (Na0.5K0.5)NbO3-(Bi0.5Na0.5)TiO3 ceramics. Appl Phys Lett 2007, 90: 092904.

Zuo RZ, Fang XS, Ye C, et al. Phase transitional behavior and piezoelectric properties of lead-free (Na0.5K0.5)NbO3-(Bi0.5K0.5)TiO3 ceramics. J Am Ceram Soc 2007, 90: 2424–2428.

Zuo RZ, Ye C. Structures and piezoelectric properties of (NaKLi)1−x(BiNaBa)xNb1−xTixO3 lead-free ceramics. Appl Phys Lett 2007, 91: 062916.

Du HL, Zhou WC, Luo F, et al. Structure and electrical properties’ investigation of (K0.5Na0.5)NbO3-(Bi0.5Na0.5)TiO3 lead-free piezo electric ceramics. J Phys D: Appl Phys 2008, 41: 085416.

Du HL, Zhou WC, Luo F, et al. Polymorphic phase transition dependence of piezoelectric properties in (K0.5Na0.5)NbO3-(Bi0.5K0.5)TiO3 lead-free ceramics. J Phys D: Appl Phys 2008, 41: 115413.

Chang YF, Yang ZP, Hou YT, et al. Effects of Li content on the phase structure and electrical properties of lead-free (K0.46−x/2Na0.54−x/2Lix)-(Nb0.76Ta0.20Sb0.04)O3 ceramics. Appl Phys Lett 2007, 90: 232905.

Chang YF, Yang ZP, Wei LL. Microstructure, density, and dielectric properties of lead-free (K0.44Na0.52Li0.04) (Nb0.96−xTaxSb0.04)O3 piezoelectric ceramics. J Am Ceram Soc 2007, 90: 1656–1658.

Hagh NM, Jadidian B, Safari A. Property-processing relationship in lead-free (K,Na,Li)NbO3 solid solution system. J Electroceram 2007, 18: 339–346.

Lin DM, Kwok KW, Chan HLW. Phase structures and electrical properties of K0.5Na0.5(Nb0.925Ta0.075)O3-LiSbO3 lead-free piezoelectric ceramics. J Phys D: Appl Phys 2007, 40: 6060–6065.

Lin DM, Kwok KW, Chan HLW. Effects of BaO on the structure and electrical properties of 0.95K0.5Na0.5(Nb0.94Sb0.06)O3-0.05LiTaO3 lead-free ceramics. J Phys D: Appl Phys 2007, 40: 6778–6783.

Qi P, Wang JF, Ming BQ, et al. Phase transition and high piezoactivity of Sb doped (Na0.53K0.435Li0.035) Nb0.94Ta0.06O3 lead-free ceramics. Chinese Phys Lett 2007, 24: 3535–3538.

Rubio-Marcos F, Ochoa P, Fernandez JF. Sintering and properties of lead-free (K,Na,Li)(Nb,Ta,Sb)O3 ceramics. J Eur Ceram Soc 2007, 27: 4125–4129.

Wu JG, Wang YY, Xiao DQ, et al. Effects of Ag content on the phase structure and piezoelectric properties of (K0.44−xNa0.52Li0.04Agx)-(Nb0.91Ta0.05Sb0.04)O3 lead-free ceramics. Appl Phys Lett 2007, 91: 132914.

Wu JG, Xiao DQ, Wang YY, et al. Effects of K/Na ratio on the phase structure and electrical properties of (KxNa0.96−xLi0.04)(Nb0.91Ta0.05Sb0.04)O3 lead-free ceramics. Appl Phys Lett 2007, 91: 252907.

Yang ZP, Chang YF, Wei LL. Phase transitional behavior and electrical properties of lead-free (K0.44Na0.52Li0.04)(Nb0.96−xTaxSb0.04)O3 piezoelectric ceramics. Appl Phys Lett 2007, 90: 042911.

Akdogan EK, Kerman K, Abazari M, et al. Origin of high piezoelectric activity in ferroelectric (K0.44Na0.52Li0.04)(Nb0.84Ta0.1Sb0.06)O3 ceramics. Appl Phys Lett 2008, 92: 112908.

Juan D, Wang JF, Zang GZ, et al. (Na0.52K0.44Li0.04)Nb0.9−xSbxTa0.1O3 lead-free piezoelectric ceramics with high performance and high Curie temperature. Chinese Phys Lett 2008, 25: 1446–1448.

Lin DM, Kwok KW, Lam KH, et al. Phase structure and electrical properties of K0.5Na0.5(Nb0.94Sb0.06)O3-LiTaO3 lead-free piezoelectric ceramics. J Phys D: Appl Phys 2008, 41: 052002.

Wu JG, Peng T, Wang YY, et al. Phase structure and electrical properties of (K0.48Na0.52)(Nb0.95Ta0.05)O3-LiSbO3 lead-free piezoelectric ceramics. J Am Ceram Soc 2008, 91: 319–321.

Zhao P, Zhang BP, Tu R, et al. High piezoelectric d33 coefficient in Li/Ta/Sb-codoped lead-free (Na,K)NbO3 ceramics sintered at optimal temperature. J Am Ceram Soc 2008, 91: 3078–3081.

Zuo RZ, Xu ZK, Li LT. Dielectric and piezoelectric properties of Fe2O3-doped (Na0.5K0.5)0.96Li0.04Nb0.86-Ta0.1Sb0.04O3 lead-free ceramics. J Phys Chem Solids 2008, 69: 1728–1732.

Wang K, Li JF. Domain engineering of lead-free Li-modified (K,Na)NbO3 polycrystals with highly enhanced piezoelectricity. Adv Funct Mater 2010, 20: 1924–1929.

Wang K, Li JF, Zhou JJ. High normalized strain obtained in Li-modified (K,Na)NbO3 lead-free piezoceramics. Appl Phys Express 2011, 4: 061501.

Zuo RZ, Fu J. Rhombohedral-tetragonal phase coexistence and piezoelectric properties of (NaK)(NbSb)O3-LiTaO3-BaZrO3 lead-free ceramics. J Am Ceram Soc 2011, 94: 1467–1470.

Shrout TR, Zhang SJ. Lead-free piezoelectric ceramics: alternatives for PZT? J Electroceram 2007, 19: 111–124.

Zhang SJ, Xia R, Shrout TR. Lead-free piezoelectric ceramics vs. PZT? J Electroceram 2007, 19: 251–257.

Takenaka T, Nagata H, Hiruma Y, et al. Lead-free piezoelectric ceramics based on perovskite structures. J Electroceram 2007, 19: 259–265.

Rödel J, Jo W, Seifert KTP, et al. Perspective on the development of lead-free piezoceramics. J Am Ceram Soc 2009, 92: 1153–1177.

Panda PK. Review: Environmental friendly lead-free piezoelectric materials. J Mater Sci 2009, 44: 5049–5062.

Safari A, Abazari M. Lead-free piezoelectric ceramics and thin films. IEEE Trans Ultrason Ferroelectr Freq Control 2010, 57: 2165–2176.

Tennery VJ, Hang KW. Thermal and X-ray diffraction studies of NaNbO3-NbO3 system. J Appl Phys 1968, 39: 4749–4753.

Ahtee M, Hewat AW. Structural phase-transitions in sodium-potassium niobate solid-solutions by neutron powder diffraction. Acta Crystallogr A 1978, 34: 309–317.

Egerton L, Dillon DM. Piezoelectric and dielectric properties of ceramics in the system potassium sodium niobate. J Am Ceram Soc 1959, 42: 438–442.

Dai YJ, Zhang XW, Chen KP. Morphotropic phase boundary and electrical properties of K1−xNaxNbO3 lead-free ceramics. Appl Phys Lett 2009, 94: 042905.

Zhou JJ, Li JF, Wang K, et al. Phase structure and electrical properties of (Li,Ta)-doped (K,Na)NbO3 lead-free piezoceramics in the vicinity of Na/K = 50/50. J Mater Sci 2011, 46: 5111–5116.

Trodahl HJ, Klein N, Damjanovic D, et al. Raman spectroscopy of (K,Na)NbO3 and (K,Na)1−xLixNbO3. Appl Phys Lett 2008, 93: 3.

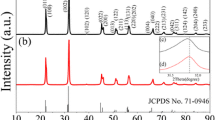

Wang K, Li JF. Analysis of crystallographic evolution in (Na,K)NbO3-based lead-free piezo-ceramics by X-ray diffraction. Appl Phys Lett 2007, 91: 262902.

Ahtee M, Glazer AM. Lattice-parameters and tilted octahedra in sodium-potassium niobate solid-solutions. Acta Crystallogr A 1976, 32: 434–446.

Shirane G, Newnham R, Pepinsky R. Dielectric properties and phase transitions of NaNbO3 and (Na,K)NbO3. Physical Review 1954, 96: 581–588.

Hewat AW. Cubic-tetragonal-orthorhombic-rhombohedral ferroelectric transitions in perovskite potassium niobate — neutron powder profile refine ment of structures. J Phys C: Solid State Phys 1973, 6: 2559–2572.

Kakimoto K, Akao K, Guo YP, et al. Raman scattering study of piezoelectric (Na0.5K0.5)NbO3-LiNbO3 ceramics. Jpn J Appl Phys 2005, 44: 7064–7067.

Kano J, Sasanuma K, Tsukada S, et al. Piezoelectric (Na0.5K0.5)NbO3-SrTiO3 ceramics in the tetragonal-orthorhombic phase boundary studied by Raman spectroscopy. Ferroelectrics 2007, 347: 55–59.

Zhou JJ, Li JF, Zhang XW. Orthorhombic to tetragonal phase transition due to stress release in (Li,Ta)-doped (K,Na)NbO3 lead-free piezoceramics. J Eur Ceram Soc 2012, 32: 267–270.

Liu W, Ren X. Large piezoelectric effect in Pb-free ceramics. Phys Rev Lett 2009, 103: 257602.

Xue D, Zhou Y, Bao H, et al. Large piezoelectric effect in Pb-free Ba(Ti,Sn)O3-x(Ba,Ca)TiO3 ceramics. Appl Phys Lett 2011, 99: 122901.

Jaeger RE, Egerton L. Hot pressing of potassium-sodium niobates. J Am Ceram Soc 1962, 45: 209–213.

Haertling GH. Properties of hot-pressed ferroelectric alkali niobate ceramics. J Am Ceram Soc 1967, 50: 329–330.

Li JF, Wang K, Zhang BP, et al. Ferroelectric and piezoelectric properties of fine-grained Na0.5K0.5NbO3 lead-free piezoelectric ceramics prepared by spark plasma sintering. J Am Ceram Soc 2006, 89: 706–709.

Zhang BP, Li JF, Wang K, et al. Compositional dependence of piezoelectric properties in NaxK1−xNbO3 lerad-free ceramics prepared by spark plasma sintering. J Am Ceram Soc 2006, 89: 1605–1609.

Wang K, Zhang BP, Li JF, et al. Lead-free Na0.5K0.5NbO3 piezoelectric ceramics fabricated by spark plasma sintering: Annealing effect on electrical properties. J Electroceram 2008, 21: 251–254.

Shen ZY, Li JF, Wang K, Electrical and mechanical properties of fine-grained Li/Ta-modified (Na,K)NbO3-based piezoceramics prepared by spark plasma sintering. J Am Ceram Soc 2010, 93: 1378–1383.

Liu N, Wang K, Li JF, et al. Hydrothermal synthesis and spark plasma sintering of (K,Na)NbO3 lead-free piezoceramics. J Am Ceram Soc 2009, 92: 1884–1887.

Zhen Y, Li JF, Wang K, et al. Spark plasma sintering of Li/Ta-modified (K,Na)NbO3 lead-free piezoelectric ceramics: Post-annealing temperature effect on phase structure, electrical properties and grain growth behavior. Mater Sci Eng B-Adv Funct Solid-State Mater 2011, 176: 1110–1114.

Arlt G, Hennings D, Dewith G. Dielectric-properties of fine-grained barium-titanate ceramics. J Appl Phys 1985, 58: 1619–1625.

Zhen YH, Li JF. Normal sintering of (K,Na)NbO3-based ceramics: influence of sintering temperature on densification, microstructure, and electrical properties. J Am Ceram Soc 2006, 89: 3669–3675.

Li JF, Zhen YH, Zhang BP, et al. Normal sintering of (K,Na)NbO3-based lead-free piezoelectric ceramics. Ceram Int 2008, 34: 783–786.

Shen ZY, Zhen YH, Wang K, et al. Influence of sintering temperature on grain growth and phase structure of compositionally optimized high-performance Li/Ta-modified (Na,K)NbO3 ceramics. J Am Ceram Soc 2009, 92: 1748–1752.

Shen ZY, Wang K, Li JF. Combined effects of Li content and sintering temperature on polymorphic phase boundary and electrical properties of Li/Ta Co-doped (Na, K)NbO3 lead-free piezoceramics. Appl Phys A 2009, 97: 911–917.

Zhen YH, Li JF. Abnormal grain growth and new core-shell structure in (K,Na)NbO3-based lead-free piezoelectric ceramics. J Am Ceram Soc 2007, 90: 3496–3502.

Wang K, Li JF. Low-temperature sintering of Li-modified (K,Na)NbO3 lead-free ceramics: Sintering behavior, microstructure, and electrical properties. J Am Ceram Soc 2010, 93: 1101–1107.

Kingery WD. Densification during sintering in the presence of a liquid phase. I. theory. J Appl Phys 1959, 30: 301–306.

Yoo J, Lee K, Chung K, et al. Piezoelectric and dielectric properties of (LiNaK)(NbTaSb)O3 ceramics with variation in poling temperature. Jpn J Appl Phys 2006, 45: 7444–7448.

Du HL, Tang FS, Luo F, et al. Effect of poling condition on piezoelectric properties of (K0.5Na0.5) NbO3-LiNbO3 lead-free piezoelectric ceramics. Mater Sci Eng B-Solid State Mater Adv Technol 2007, 137: 175–179.

Du HL, Zhou WC, Luo F, et al. An approach to further improve piezoelectric properties of (K0.5Na0.5)NbO3-based lead-free ceramics. Appl Phys Lett 2007, 91: 202907.

Ogawa T, Furukawa M, Tsukada T. Poling field dependence of piezoelectric properties and hysteresis loops of polarization versus electric field in alkali niobate ceramics. Jpn J Appl Phys 2009, 48.

Rubio-Marcos F, Romero JJ, Ochoa DA, et al. Effects of poling process on KNN-modified piezo-ceramic properties. J Am Ceram Soc 2010, 93: 318–321.

Morozov MI, Kungl H, Hoffmann MJ. Effects of poling over the orthorhombic-tetragonal phase transition temperature in compositionally homogeneous (K,Na)NbO3-based ceramics. Appl Phys Lett 2011, 98.

Zuo RZ, Fu J, Lv DY. Phase transformation and tunable piezoelectric properties of lead-free (Na0.52K0.48−Xlix)(Nb1−x−ySbyTax)O3 system. J Am Ceram Soc 2009, 92: 283–285.

Gao Y, Zhang J, Qing Y, et al. Remarkably strong piezoelectricity of lead-free (K0.45Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3 ceramic. J Am Ceram Soc 2011, 94: 2968–2973.

Safari A, Akdogan EK. Piezoelectric and Acoustic Materials for Transducer Applications. New York: Springer, 2008.

Zhen YH, Li JF, Wang K. Fabrication and electrical properties of fine-scale 1–3 piezoceramic/epoxy composites using (K,Na)NbO3-based lead-free ceramics. Ferroelectrics 2007, 358: 1043–1050.

Shen ZY, Xu Y, Li JF. Fabrication and electromechanical properties of microscale 1-3-type piezoelectric composites using (Na,K)NbO3-based Pb-free piezoceramics. J Appl Phys 2009, 105.

Shen ZY, Li JF, Chen R, et al. Microscale 1-3-type (Na,K)NbO3-based Pb-free piezocomposites for high-frequency ultrasonic transducer applications. J Am Ceram Soc 2011, 94: 1346–1349.

Shung KK, Cannata JM, Zhou QF. Piezoelectric materials for high frequency medical imaging applications: a review. J Electroceram 2007, 19: 139–145.

Guo M, Lam KH, Lin DM, et al. A rosen-type piezoelectric transformer employing lead-free K0.5Na0.5NbO3 ceramics. J Mater Sci 2008, 43: 709–714.

Hagh NM, Jadidian B, Ashbahian E, et al. Lead-free piezoelectric ceramic transducer in the donor-doped K1/2Na1/2NbO3 solid solution system. IEEE Trans Ultrason Ferroelectr Freq Control 2008, 55: 214–224.

Kwok KW, Hon SF, Lin D. Lead-free self-focused piezoelectric transducers for viscous liquid ejection. Sensor Actuat a-Phys 2011, 168: 168–171.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Wang, K., Li, JF. (K, Na)NbO3-based lead-free piezoceramics: Phase transition, sintering and property enhancement. J Adv Ceram 1, 24–37 (2012). https://doi.org/10.1007/s40145-012-0003-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-012-0003-3