Abstract

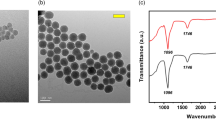

In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, cost-effective, and green approach. The sol–gel method was also used to produce these NPs as a comparative method. The SiO2 NPs produced by both methods were characterized using high-resolution transmission electron microscopy (HRTEM), dynamic light scattering (DLS), energy-dispersive X-ray analysis (EDX), Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), X-ray fluorescence (XRF), and Brunauer–Emmett–Teller (BET). In the ball mill technique, different parameters, such as milling rotation speed (6–240 rpm), powder-to-ball ratio (1:5, 1:10, 1:20 kg), milling time (3–12 h), air blowing speed (7.5–30 km/h), and air suction speed (50, 100, and 200 m3/h), were optimized. The optimum conditions were found to be 240 rpm, 1:20 kg, 12 h, 7.5 km/h, and 50 m3/h for the rotating speed, powder-to-ball ratio, milling time, air blowing speed, and air sucking speed, respectively. Six steps were designed for the preparation of NPs in this ball mill, and the minimum particle size under the optimum conditions was obtained at 16.6 nm at step 6. The high purity of SiO2 particles in large volumes with particle sizes from μm to nm was achieved. The produced NPs can be used in the cosmetics industries, dentistry, and other fields.

Graphical abstract

The cylindrical iron pipe was provided. Both sides of the cylindrical pipe were placed continuously to input and output the materials in the mill system. The rectangular iron table was made and the cylindrical iron pipe was assembled on the table. To rotate the planetary ball mill system, the electromotor was installed under the table, and to control the rotation speed, an inverter was installed. An adjustability air blower to adjust the inlet air pressure was installed. At the outlet of the mill, a separating tower was designed, which is connected to the separating tower from the mill outlet by fittings. The regulator dimmer was installed at the end of the tower, and the air suction device was installed to control the power and speed of air suction, which is equipped with a suction device. The surface of the inner iron walls of the cylinder was covered with cut silica stones. Before installing the inner walls and ball to the mill, the silica stones of the inner walls and the grinding ball were washed by HCL solution and then the deionized water.

Similar content being viewed by others

Data availability

Authors are not allowed to make data available.

References

Nasrollahzadeh, M., Mohammad Sajadi, S., Sajjadi, M., Issaabadi, Z.: Chapter 1-An Introduction to Nanotechnology. Interface Sci. Technol. 28: 1–27 (2019).

Panchal, H., Patel, H., Patel, J., Shah, M.: A systematic review on nanotechnology in enhanced oil recovery. Pet. Res. 6, 204–212 (2021)

Khan, I., Saeed, K., Khan, I.: Nanoparticles: properties, applications and toxicities. Arab. J. Chem. 12, 908–931 (2019)

Ab Rahman, I., Padavettan, V.: Synthesis of Silica Nanoparticles by Sol-Gel: Size-Dependent Properties, SurfaceModification, and Applications in Silica-Polymer Nanocomposites-A Review. J. Nanomater. 2012, 1687–4110 (2012)

Munasir, M., Triwikantoro, T., Zainuri, M., Darminto, D.: Synthesis of SiO2 nanopowders containing quartz and cristobalite phases from silica sands. Mater. Sci. -Pol. 33, 47–55 (2015)

Hussain, Z.: Comparative study on improving the ball mill process parameters influencing on the synthesis of ultrafine silica sand: a taguchi coupled optimization technique. Int. J. Precis. Eng. Man. 22, 679–688 (2021)

Cao, Y., Khan, A., Abdi, A., Ghadiri, M.: Combination of RSM and NSGA-II algorithm for optimization and prediction of thermal conductivity and viscosity of bioglycol/water mixture containing SiO2 nanoparticles. Arab. J. Chem. 14, 103204 (2021)

Yuan, D., Ellis, C.M., Davis, J.J.: Mesoporous silica nanoparticles in bioimaging. Materials. 13, 3795 (2020)

Manzano, M., Vallet-Regí, M.: Mesoporous silica nanoparticles for drug delivery. Adv. Funct. Mater. 30, 1902634 (2020)

Zhou, Y., Quan, G., Wu, Q., Zhang, X., Niu, B., Wu, B., Huang, Y., Pan, X., Wu, C.: Mesoporous silica nanoparticles for drug and gene delivery. Acta Pharm. Sin. B. 8, 165–177 (2018)

Bayir, S., Barras, A., Boukherroub, R., Szunerits, S., Raehm, L., Richeter, S., Durand, J.O.: Mesoporous silica nanoparticles for recent photodynamic therapy applications. Photochem. Photobiol. Sci. 17, 1651–1674 (2018)

Yang, Y., Zhang, M., Song, H., Yu, C.: Silica-based nanoparticles for biomedical applications: from nanocarriers to biomodulators. Acc. Chem. Res. 53, 1545–1556 (2020)

Briceño-Ahumada, Z., Soltero-Martínez, J.F.A., Castillo, R.: Aqueous foams and emulsions stabilized by mixtures of silica nanoparticles and surfactants: a state-of-the-art review. Chem. Eng. J. Adv. 7, 100116 (2021)

Banerjee, S., Das, J., Alvareza, R.P., Santra, S.: Silica nanoparticles as a reusable catalyst: a straightforward route for the synthesis of thioethers, thioesters, vinyl thioethers and thio-Michael adducts under neutral reaction conditions. New J. Chem. 34, 302–306 (2010)

Vazquez, N.I., Gonzalez, Z., Ferrari, B., Castro, Y.: Synthesis of mesoporous silica nanoparticles by sol–gel as nanocontainer for future drug delivery applications. Bol. Soc. Esp. Ceram. Vidr. 56, 139–145 (2017)

Gomes, A.L.M., Andrade, P.H.M., Palhares, H.G., Dumont, M.R., Soares, D.C.F., Volkringer, C., Houmard, M., Nunes, E.H.M.: Facile sol-gel synthesis of silica sorbents for the removal of organic pollutants from aqueous media. J. Mater. Res. Technol. 15, 4580–4594 (2021)

Saravanan, S., Dubey, R.S.: Synthesis of SiO2 nanoparticles by Sol-Gel method and their optical and structural properties. Rom. J. Inf. Sci. Technol. 23, 105–112 (2020)

Stopic, S., Wenz, F., Husovic, T.V., Friedrich, B.: Synthesis of silica particles using ultrasonic spray pyrolysis method. Metals. 11, 463 (2021)

Rizlan, Z., Mamat, O.: Process Parameters optimization of silica sand nanoparticles production using low speed ball milling method. Chin. J. Eng. 2014, 1–4 (2014)

Bramhe, S.N., Young Park, J., Hwangbo, S.A., Cheol Chu, M.: Facile synthesis of surfactant-free SiO2 nanoparticles via emulsion method. Adv Powder Technol. 27, 2541–2545 (2016)

Gh Jeelani, P., Mulay, P., Venkat, R., Ramalingam, C.: Multifaceted application of silica nanoparticles. A Review. Silicon. 12, 1337–1354 (2020)

Kumar, A., Yadav, N., Bhatt, M., Mishra, N.K., Chaudhary, P., Singh, R.: Sol–Gel derived nanomaterials and it’s applications: a review. Res J Chem Sci. 5, 98–105 (2015)

Piras, C. C., Fern´andez-Prieto, S., De Borggraeve, W. M.: Ball milling: a green technology for the preparation and functionalisation of nanocellulose derivatives. Nanoscale Adv. 1: 937–947 (2019).

Ijaz, I., Gilani, E., Nazir, A., Bukhari, A.: Detail review on chemical, physical and green synthesis, classification, characterizations and applications of nanoparticles. Green Chem Lett Rev. 13, 223–245 (2020)

Yuan, R., Dong, Y., Hou, R., Shang, L., Zhang, J., Zhang, S., Chen, X., Song, H.: Structural transformation of porous and disordered carbon during ball-milling. J. Chem. Eng. 454, 140418 (2023)

Sherif El-Eskandarany, M., Al-Hazza, A., Al-Hajji, L.A., Ali, N., Al-Duweesh, A.A., Banyan, M., Al-Ajmi, F.: Mechanical milling: a superior nanotechnological tool for fabrication of nanocrystalline and nanocomposite materials. Nanomaterials 11, 2484 (2021)

Eikeland Nilssen, B., Arne Kleiv, R.: Silicon powder properties produced in a planetary ball mill as a function of grinding time, grinding bead size and rotational speed. SILICON 12, 2413–2423 (2020)

Wang, P., Hu, J., Liu, T., Han, G., Ma, W., Li, J.: New insights into ball-milled zero-valent iron composites for pollution remediation: an overview. J. Clean. Prod. 385, 135513 (2023)

Akl, M.A., Aly, H.F., Soliman, H.M.A., Abd ElRahman, A.M.E., Abd-Elhamid, A.I.: Preparation and Characterization of Silica Nanoparticles by Wet Mechanical Attrition of White and Yellow Sand. J. Nanomed. Nanotechnol. 4: 6 (2013).

Ismail, A., Saputri, L.N.M.Z., Dwiatmoko, A.A., Susanto, B.H., Nasikin, M.: A facile approach to synthesis of silica nanoparticles from silica sand and their application as superhydrophobic material. J. Asian Ceram. Soc. 9, 665–672 (2021)

Prasad, T., Halder, S., Dhar, S.S.: Process parameter effects on particle size reduction of sol-gel synthesized silica nanoparticles. Mater. Today: Proc. 22, 1669–1675 (2020)

Fahad, H.G., Hammadi, O.A.: Characterization of Highly-Pure Silicon Dioxide Nanoparticles as Scattering Centers for Random Gain Media. Iraqi J. Appl. Phys. 16, 37–42 (2020)

Khademolhosseini, R., Jafari, A., Mohammad Mousavi, S., Manteghian, M., Fakhroueian, Z.: Synthesis of silica nanoparticles with different morphologies and their effects on enhanced oil recovery. Appl. Nanosci. 10, 1105–1114 (2020)

Dubey, R.S., Rajesh, Y.B.R.D., More, M.A.: Synthesis and characterization of SiO2 nanoparticles via sol-gel method for industrial applications. Mater. Today: Proc. 2, 3575–3579 (2015)

Aien Mohamed Abdul Ghani, N. N., Alam Saeed, M., Hazwani Hashim, I.: Thermoluminescence (TL) response of silica nanoparticles subjected to 50 Gy gamma irradiation, Mal. J. Fund. Appl. Sci. 13: 178–180 (2017).

Amiri, Sh., Sohrabi, M.R., Motiee, F.: Optimization removal of the ceftriaxone drug from aqueous media with novel zero-valent iron supported on doped strontium hexaferrite nanoparticles by response surface methodology. ChemistrySelect 5, 5831–5840 (2020)

Farhadi, Sh., Sohrabi, M.R., Motiee, F., Davallo, M.: Organophosphorus diazinon pesticide removing from aqueous solution by zero-valent iron supported on biopolymer chitosan: rsm optimization methodology. J Polym Environ. 29, 103–120 (2021)

Salah, N., Habib, S.S., Khan, Z.H., Memic, A., Azam, A., Alarfaj, E., Zahed, N., Al-Hamedi, S.: High-energy ball milling technique for ZnO nanoparticles as antibacterial material. Int J Nanomedicine. 6, 863–869 (2011)

Giri, P.K., Bhattacharyya, S., Singh, D.K., Kumar Panigrahi, B.: Correlation between microstructure and optical properties of ZnO nanoparticles synthesized by ball milling. J. Appl. Phys 102, 093515 (2007)

Yang, B., Chen, D.: Synthesis of CuO nanoparticles for catalytic application via ultrasound-assisted ball milling. Process. Appl. Ceram. 11, 39–44 (2017)

Yadav, B.C., Singh, S., Yadav, T.P.: Titania prepared by ball milling: its characterization and application as liquefied petroleum gas sensor. Synth. React. Inorg. Met. Org. Chem. Nano-Met. Chem. 45, 487–494 (2015)

Khayati, G.R., Janghorban, K.: The nanostructure evolution of Ag powder synthesized by high energy ball milling. Adv Powder Technol. 23, 393–397 (2012)

Arbain, R., Othman, M., Palaniandy, S.: Preparation of iron oxide nanoparticles by mechanical milling. Miner. Eng. 24, 1–9 (2011)

Jiang, A., Wang, F., Xia, D., Li, M., Qiang, L., Zhu, Z., Wang, P., Fan, R., Lin, K., Yang, Y.: Aluminum nanoparticles manufactured using a ball-milling method with ammonium chloride as a grinding aid: achieving energy release at low temperature. New J. Chem. 43, 1851 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karimkhani, S., Derakhshi, P., Aberoomand Azar, P. et al. Facile, fast, and green preparation of high-purity and quality silica nanoparticles using a handmade ball mill: comparison with the sol–gel method. J Nanostruct Chem (2023). https://doi.org/10.1007/s40097-022-00522-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40097-022-00522-0