Abstract

In the present work, anodizing of zinc foil was investigated in NaOH and oxalic acid electrolytes under the influence of different concentrations of the electrolyte, while temperature and voltage were kept constant. Anodized zinc plates were characterized using scanning electron microscope (SEM), UV–Vis diffuse reflectance spectroscopy (DRS UV–Vis), and X-ray diffraction (XRD) analysis. Characterization of anodized Zn plates using SEM showed that their morphology was significantly influenced by the type and concentration of anodizing electrolyte. XRD analysis indicated that the ZnO thin films were of hexagonal wurtzite structures. From contact angle measurements, it has been observed that the contact angle of anodized film is higher than that of pure zinc foil. Antibacterial results suggest that the parent zinc foil did not show the antibiotic activity, but the anodized zinc oxide is effective both toward Gram-positive bacteria and Gram-negative bacteria.

Similar content being viewed by others

Introduction

Zinc oxide is a low-cost, non-toxic material with a wide bandgap of 3.37 eV, natural n-type electrical conductivity, and having a wurtzite structure. Because of its optical, electrical, and piezoelectric properties, this semiconductor is used as photocatalyst. Other applications of zinc oxide are light-emitting diodes, lasers, field-emission devices, and chemical sensors [1]. In several surveys over the past two decades, zinc oxide has been shown to possess activity against a broad spectrum of Gram-positive and Gram-negative bacteria [2–5]. Sawai et al. attributed the antimicrobial action of zinc oxide powder slurry to the liberation of hydrogen peroxide; they suggested that hydrogen peroxide crosses the microbial cell membrane, resulting in growth inhibition or destruction [2]. In subsequent work, Sawai et al. showed efficacy by zinc oxide against S. aureus, which was attributed to the strong affinity between zinc oxide and S. aureus cells [3]. Zhang et al. showed that zinc oxide exhibits bacteriostatic activity against E. coli. Scanning electron microscopy data suggested that zinc oxide–bacteria direct interactions may have damaging and breakdown of bacterial cell membranes [4]. Skoog et al. suggest that zinc oxide-coated nanoporous alumina membranes have activity against some microorganisms, such as B. subtilis, E. coli, S. aureus, and S. epidermidis in agar diffusion assays. On the other hand, the zinc oxide-coated membranes did not show activity against P. aeruginosa, E. faecalis, and C. albicans [5].

To date, varying methods were reported to fabricate ZnO nanostructures, for example, vapor-phase transport, metalorganic chemical-vapor deposition, laser ablation, thermal decomposition, a template-directed method, and chemical synthesis have been engaged to produce ZnO hexagram whiskers, quantum dots, nanorods, nanowires, etc. [1–9]. These ZnO nanostructures are generally fabricated under complex process control, high reaction temperatures, long reaction times, expensive chemicals, and a specific method for specific nanostructures [3–5]. Among these methods, electrochemical synthesis is favored by many due to its simplicity, low-temperature operation process, viability of commercial production, flexibility, and relatively low cost. Anodizing is a well-known route to synthesize low-dimensional self-organized structures. As it was discussed previously, the antibacterial effect of ZnO nanoparticles was extensively studied. On the other hand, many works have been done on the anodizing of zinc foil. But up to our knowledge, there are no reports on the antibacterial properties of anodized ZnO structures in the literature. In the present work, anodizing of the zinc foil was investigated in NaOH and oxalic acid electrolytes under the influence of different concentrations of the electrolyte, while the temperature and voltage were kept constant.

Experimental

Sample preparation

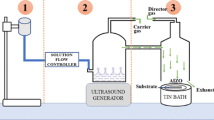

The electrolytes for zinc anodizing were 0.1, 0.3, and 0.5 M NaOH and oxalic acid aqueous solutions. A steel sheet (Dirgodazazar Co., Tabriz, Iran) was used as the cathode. A zinc foil (0.1-mm thick and purity >99.9 %, Dirgodazazar Co., Tabriz, Iran) sonicated in ethanol for 5 min with a surface area of 0.78 cm2 and was used as the working electrode. The anodizing process was conducted at a constant voltage of 10 V for 60 min at room temperature. Immediately after anodizing, the zinc foil was washed with distilled water and dried in a warm airflow.

Characterization

The morphology of samples was observed with a scanning electron microscope (LEO 1430VP, Germany). X-ray diffraction (XRD) was carried out using Philips PW 1050 diffractometer (The Netherlands). UV–Vis diffuse reflectance spectroscopy (DRS UV–Vis) was taken in the wavelength range of 200–800 nm using a spectrophotometer (Scinco S4100, S. Korea).

Static contact angles were measured with a handmade contact angle meter at room temperature. Water droplets of approximately 5 µL were dropped gently onto the surface of a sample. Three points of each sample were tested, and the average value of the three left and right contact angles was calculated as the determined static contact angle [10, 11].

Antibacterial activity

The bacterial strains used for the antibacterial activity were Gram-negative E. coli (PTCC 1270) and Gram-positive S. aureus (PTCC 1112) obtained from the Iranian Research Organization for Science and Technology (Tehran, Iran). The antibacterial activity of the samples was tested by the agar diffusion test. Samples were exposed to bacteria in solid media (nutrient agar), and the inhibition zone around each sample was quantified and put down as the antibacterial effect. Agar plates were inoculated with 100-µL suspensions of bacteria. Then, anodized samples were placed on agar plates and covered at 37 °C for 24 h. The inhibition zone for bacterial growth was observed visually [12].

Results and discussion

Development mechanism of ZnO film, the growth mechanism, and formation of ZnO layer on the surface of Zn sheet take place under the influence of constant applied voltage. When the acidic solution (oxalic acid) was employed as the electrolyte, as described in most studies [7, 8], the possible mechanism for the process can be expressed equally:

The zinc sheet (anode) was converted to Zn2+ ions by releasing two electrons which moved toward the cathode. The water molecules were ionized into H+ and OH− ions. H2 were liberated at the cathode; hence, pH of the solution was changed from the acidic to basic one. Finally, remaining OH− ions move toward the anode resulting in the formation of Zn(OH)2. However, in the basic medium (NaOH electrolyte), the possible mechanism for the process can be expressed as:

The initial phase of the reaction is the active dissolution of Zn, which is ascribed to the formation of \({\text{Zn}}({\text{OH}})_{4}^{2 - }\). When the concentration of \({\text{Zn}}({\text{OH}})_{4}^{2 - }\) exceeds the solubility product of Zn(OH)2, precipitation of a compact layer of Zn(OH)2 will occur on the anode surface. Finally, ZnO will form.

Surface morphology of the anodized zinc plates

Figures 1 and 2 show the SEM images of Zn plates anodized in NaOH and oxalic acid electrolytes at 25 °C and 10 V for 1 h, respectively. In general, it seems that the electrochemical condition is an important ingredient for the organization of nanostructures. When using different electrolytes for the anodizing of the zinc foil and while keeping other parameters constant, different ZnO nanostructure arrays were observed. As presented in Fig. 1a, in an electrolyte of NaOH, a ZnO nano and micro hole array was formed, whereas in oxalic acid (Fig. 2a), a ZnO nanoparticle array was observed. This study further confirms that different types of electrolytes produce different morphologies of ZnO.

Figure 1 shows the SEM images of the Zn plates anodized in NaOH electrolyte. The obtained SEM images showed that the morphologies of the anodized Zn plates were significantly influenced by electrolyte concentration. The surfaces were relatively flat and with parallel scratches which were believed to be originated from the mechanical grinding and polishing process. As can see in Fig. 1, some holes distributed over the entire surface. These holes were randomly spread over the surface of the anodized Zn plate. The size of holes increased as the concentration of electrolyte increased. This suggests that the concentration of electrolyte plays an important role in the determination of hole size.

Figure 2 displays the SEM images of the anodic ZnO nanoparticles formed in 0.1, 0.3, and 0.5 M oxalic acid solution under anodic voltages of 10 V. It can be seen that for Zn plates anodized in oxalic acid, no holes was formed. However, nanoporous structures were discovered along the surface of the Zn plate anodized in mentioned concentration of oxalic acid. These nanostructures were distributed over the surface of the anodized Zn plate. At a lower oxalic acid concentration (0.1 M), the formation of nanoparticles was incomplete. By increasing the oxalic acid concentration to 0.5 M (Fig. 2c), a nanoparticle array was completely formed. Different from anodic ZnO structures, some larger ZnO particles can be observed to distribute on the substrate surface of the sample. Moreover, these molecules and nanostructures cannot be seen along the sample surface before anodizing. They should be produced in the anodic process.

It seems that using sodium hydroxide causes serious corrosion due to its high corrosion characteristics. Sodium hydroxide is a strong base and has the ability of creation of holes on the zinc surface. Hence, oxalic acid is a weak organic acid, and it can affect the zinc surface poorly.

The results were in good consistent with the observation reported by Shetty and Nanda, in which the Zn plates were anodized in deionized water [13]. They reported that morphologies of the ZnO thin film were significantly dependent on the anodizing voltage. However, no nanostructure was reported on their findings. Instead, wall-like construction was formed at 1 V, which changed gradually to well-defined porous structure, as the voltage increased to 9 V [6].

XRD patterns

To identify the composition of the nanoporous structures, the anodized Zn plates were characterized using the XRD. The XRD patterns of the anodized zinc foil using oxalic acid and NaOH as electrolytes are shown in Fig. 3. It can be observed that peaks attributed to Zn and ZnO were present in these XRD patterns. The presence of Zn peaks were due to the Zn plates which were used as substrates in this study. The peaks at scattering angles (2θ) of 38.61, 44.82, and 64.89 correspond to the reflection from 101,102, and 103 crystal planes, respectively. The XRD pattern is identical to the hexagonal phase with wurtzite structure [5, 6, 14].

Optical properties

Optical properties of the anodized Zn plates were characterized based on UV–Vis absorption spectra shown in Fig. 4. The calculated bandgap of ZnO film is around 3.2 eV. Concentration changes have not a big effect on the bandgap, but the more concentration of the electrolyte; the more porous of produced nanostructure and, consequently, its surface is increased, and thus, the absorption of light is increased by the sample.

Contact angle measurement

Table 1 shows the change in contact angle of pure zinc foil and the anodized film. It is evident that the anodizing induces a remarkable change in the surface properties of the films. Water contact angle testing results confirmed that the surface of pure zinc foil was hydrophilic with an angle of 87.3 ± 2.3°. It has been noticed that the contact angle of the anodized film is less than that of pure zinc foil. This fact confirms that anodized films are more hydrophilic for both electrolytes.

With referring to Table 1, one can see that the contact angle for each electrolyte increases with increasing anodizing time. From the values of the contact angle and the SEM images, we can observe that the value of the contact angle is directly correlated with the surface structure of the film. The reason of the increment of contact angel has been explicated in terms of the quantity of air spaces observed in the nanoscale in an earlier work [11, 15]. The trapped air pressure balances the gravity of the water droplet, and the surface tension of the water tries to keep the shape of the droplet spherical. Hence, the film with high intensity of air displays higher hydrophobic characteristics. The biggest value of the contact angle in the case of different anodized samples can be assigned to the high intensity of air entrapped in the film surface.

Antimicrobial activity

The disinfectant properties of samples were investigated with Gram-negative E. coli and Gram-positive S. aureus at 37 °C for 24 h. Parent zinc foil did not show the antibiotic activity. The zones of growth inhibition were observed for the anodized zinc foils in all the cases (Fig. 5). These results are summarized in Table 2. The zones of growth inhibition for E. coli and S. aureus were 5.7–6.3 and 5.3–6.5 mm, respectively. Thus, these results suggest that the anodized zinc oxide is not only effective toward Gram-positive bacteria, but also Gram-negative bacteria. On the other hand, the antibacterial activity is relatively uniform for all samples (Table 2).

Three distinct mechanisms of action have been put forward in the literature for the zinc oxide antimicrobial activity: (i) the production of reactive oxygen species (ROS) because of the semiconductor properties of ZnO, (ii) the destabilization of microbial membranes upon direct contact of ZnO particles to the cell walls, and (iii) the intrinsic antimicrobial properties of Zn2+ ions released by ZnO in aqueous medium [9]. Since ZnO particles were unable to disperse out of the anodized samples, antimicrobial species have necessarily been arisen from the released Zn2+ to the agar medium and direct contact of bacteria with anodized surface.

Conclusion

In the present work, ZnO nanostructures were successfully fabricated by anodizing a Zn sheet in sodium hydroxide (NaOH) and oxalic acid electrolytes under the influence of different concentrations of the electrolyte, while the temperature and voltage were kept constant. Characterization of anodized Zn plates using SEM showed that their morphology was significantly influenced by the type and concentration of anodizing electrolyte. The structural characterization showed that the anodic ZnO had hexagonal wurtzite structure. From contact angle measurements, it has been observed that the contact angle of anodized film is higher than that of pure zinc foil. Antibacterial results suggest that the parent zinc foil did not show the antibiotic activity, but the anodized zinc oxide is effective both toward Gram-positive bacteria and Gram-negative bacteria.

References

Secu, C.E., Sima, M.: Photoluminescence and thermoluminescence of ZnO nano-needle arrays and films. Opt. Mater. 31, 876–880 (2009)

Sawai, J., Shoji, S., Igarashi, H., Hashimoto, A., Kokugan, T., Shimizu, M., Kojima, H.: Hydrogen peroxide as an antibacterial factor in zinc oxide powder slurry. J. Ferment. Bioeng. 86, 521–522 (1998)

Sawai, J.: Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. J. Microbiol. Methods 54, 177–182 (2003)

Zhang, L.L., Jiang, Y.H., Ding, Y.L., Povey, M., York, D.: Investigation into the antibacterial behaviour of suspensions of ZnO nanoparticles (ZnO nanofluids). J. Nanopart. Res. 9, 479–489 (2007)

Skoog, S.A., Bayati, M.R., Petrochenko, P.E., Stafslien, S., Daniels, J., Cilz, N., Comstock, D.J., Elam, J.W., Narayan, R.J.: Antibacterial activity of zinc oxide-coated nanoporous alumina. Mater. Sci. Eng. B 177, 992–998 (2012)

Voon, C.H., Derman, M.N., Hashim, U., Lim, B.Y., Sam, S.T., Foo, K.L., Ten, S.T.: Synthesis of nanoporous zinc oxide by anodizing of zinc in distilled water. Appl. Mech. Mater. 754–755, 1126–1130 (2015)

Huang, G.S., Wu, X.L., Cheng, Y.C., Shen, J.C., Huang, A.P., Chu, P.K.: Fabrication and characterization of anodic ZnO nanoparticles. Appl. Phys. A 86, 463–467 (2007)

Goh, H.S., Adnan, R., Farrukh, M.A.: ZnO nanoflake arrays prepared via anodizing and their performance in the photodegradation of methyl orange. Turk. J. Chem. 35, 375–391 (2011)

Pasqueta, J., Chevalierb, Y., Pelletierb, J., Couvala, E., Bouviera, D., Bolzingerb, M.A.: The contribution of zinc ions to the antimicrobial activity of zinc oxide. Colloid Surf. A 457, 263–274 (2014)

Ghorbanpour, M.: Optimization of sensitivity and stability of Au/Ag bilayer thin films used in surface plasmon resonance chips. J. Nanostruct. 3, 309–313 (2013)

Ghorbanpour, M., Falamaki, C.: A novel method for the fabrication of ATPES silanized SPR sensor chips: exclusion of Cr or Ti intermediate layers and optimization of optical/adherence properties. Appl. Surf. Sci. 301, 544–550 (2014)

Pouraboulghasem, H., Ghorbanpour, M., Shayegh, R., Lotfiman, S.: Synthesis, characterization and antimicrobial activity of alkaline ion-exchanged ZnO/bentonite nanocomposites. J. Cent. S. Univ. 23, 787–792 (2016)

Shetty, A., Nanda, K.K.: Synthesis of zinc oxide porous structures by anodization with water as an electrolyte. Appl. Phys. A 109, 151–157 (2012)

Zhao, J., Wang, X., Liu, J., Meng, Y., Xu, X., Tang, C.: Controllable growth of zinc oxide nanosheets and sunflower structures by anodization method. Mater. Chem. Phys. 126, 555–559 (2011)

He, S., Zheng, M., Yao, L., Yuan, X., Li, M., Ma, L., Shen, W.: Preparation and properties of ZnO nanostructures by electrochemical anodization method. Appl. Surf. Sci. 256, 2557–2562 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gilani, S., Ghorbanpour, M. & Parchehbaf Jadid, A. Antibacterial activity of ZnO films prepared by anodizing. J Nanostruct Chem 6, 183–189 (2016). https://doi.org/10.1007/s40097-016-0194-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-016-0194-1