Abstract

Temperature, steam flow rate and coal/biomass ratio in the feedstock are the key factors that affect the performances of co-gasification processes. A three-dimensional computational fluid dynamics (CFD) method matched with homogenous chemical reactions was used to visualize hydrogen concentration gradient in a fixed-bed reactor. The Eulerian–Eulerian CFD method was promoted to investigate the effects of various ranges of temperature (700–950 °C), water flow rate (0.5 × 10–8 to 3.3 × 10–8 m3/s) and coal/biomass ratio (0–100%) on the gasification efficiency. All numerical operations were under time-dependent conditions by depicting concentration contours for H2 production. Using the CFD technique, the desirable circumstances for maximum H2 production were specified as temperature of 850 °C, water flow rate of 1.9 × 10−3 m3/s and coal/biomass ratio of around 50%. A comparison between the simulation results and experimental gasification data was conducted to approve the CFD results, and there was an acceptable agreement among them.

Similar content being viewed by others

Abbreviations

- R i :

-

Production rate of hydrogen (mol/m3/s)

- u :

-

Velocity vector

- M ij :

-

Interphase coupling term

- C :

-

Concentration (mol/m3)

- F :

-

Volume force (N/m3)

- F m :

-

Interphase momentum transfer (N/m3)

- P :

-

Pressure (Pa)

- d P :

-

Solid nominal diameter (m)

- X exp. :

-

Concentration of H2 in the experimental paper (mol/m3)

- X sim :

-

Concentration of H2 in simulated results (mol/m3)

- m :

-

Mass of the mixture (kg)

- C p :

-

Specific heat capacity

- Q cond :

-

Heat transfer in the domain through the conduction (J)

- Q conv :

-

Heat transfer in the domain through the convection (J)

- φ :

-

Phase volume fraction

- τ :

-

Viscous stress tensor (Pa)

- µ :

-

Dynamic viscosity (Pa*s)

References

Secer, A., Hasanoglu, A.: Evaluation of the effects of process parameters on co- gasification of Çan lignite and sorghum biomass with response surface methodology: an optimization study for high yield hydrogen production. Fuel 259, 116230 (2020)

Tian, X., Niu, P., Ma, Y., Zhao, H.: Chemical-looping gasification of biomass: part II. Tar yields and distributions. Biomass Bioener. 108, 178–189 (2018)

Torres, C., Urvina, L., de Lasa, H.: A chemical equilibrium model for biomass gasification. Application to Costa Rican coffee pulp transformation unit. Biomass Bioener. 123, 89–103 (2019)

Vonka, G., Piriou, B., Wolbert, D., Cammarano, C., Vaïtilingom, G.: Analysis of pollutants in the product gas of a pilot scale downdraft gasifier fed with wood, or mixtures of wood and waste materials. Biomass Bioener. 125, 139–150 (2019)

Kumar, U., Salem, A.M., Paul, M.C.: Investigating the thermochemical conversion of biomass in a downdraft gasifier with a volatile break-up approach. Energy Proc. 142, 822–828 (2017)

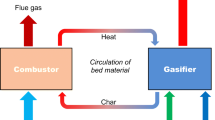

Yaghoubi, E., Xiong, Q., Doranehgard, M.H., Yeganeh, M.M., Shahriari, Gh., Bidabadi, M.: The effect of different operational parameters on hydrogen rich syngas production from biomass gasification in a dual fluidized bed gasifier. Chem. Eng. Process. 126, 210–221 (2018)

Zhang, Y., Li, L., Xu, P., Liu, B., Shuai, Y., Li, B.: Hydrogen production through biomass gasification in supercritical water: a review from exergy aspect. Int. J. Hydrog. Energy 44, 15727–15736 (2019)

Jin, K., Ji, D., Xie, Q., Nie, Y., Yu, F., Ji, J.: Hydrogen production from steam gasification of tableted biomass in molten eutectic carbonates. Int. J. Hydrog. Energy 44, 22919–22925 (2019)

Tavares, R., Monteiro, E., Tabet, F., Rouboa, A.: Numerical investigation of optimum operating conditions for syngas and hydrogen production from biomass gasification using Aspen Plus. Renew. Energy 146, 1309–1314 (2020)

Safarian, S., Unnþórsson, R., Richter, Ch.: A review of biomass gasification modelling. Renew. Sust. Energy Rev. 110, 378–391 (2019)

Amani, A., Jalilnejad, E.: CFD modeling of formaldehyde biodegradation in an immobilized cell bioreactor with disc-shaped Kissiris support. Biochem. Eng. 122, 47–59 (2017)

Amani, A., Jalilnejad, E., Mousavi, S.M.: Simulation of phenol biodegradation by Ralstonia Eutropha in a Packed-bed bioreactor with batch recycle mode using CFD technique. J. Ind. Eng. Chem. 59, 310–319 (2018)

Zhao, L., Lu, Y.: Hydrogen production by biomass gasification in a supercritical water fluidized bed reactor: a CFD-DEM study. J. Supercrit. Fluid 131, 26–36 (2018)

Ku, X., Li, T., Løvås, T.: CFD–DEM simulation of biomass gasification with steam in a fluidized bed reactor. Chem. Eng. 122, 270–283 (2015)

Kumar, U., Paul, M.C.: CFD modelling of biomass gasification with a volatile break-up approach. Chem. Eng. 195, 413–422 (2019)

Wachem, B.G.M.V., Schouten, J.C., Bleek, C.M.V.D.: Comparative analysis of CFD models of dense gas-solid systems. AlChE J. 47, 1035–1051 (2001)

Attou, A., Ferschneider, G.: A two-fluid model for tow regime transition in gas liquid trickle-bed reactors. Chem. Eng. Sci. 59, 5031–5037 (1999)

Mallick, D., Mahanta, P., Moholkar, V.S.: Co-gasification of coal and biomass blends: chemistry and engineering. Fuel 204, 106–128 (2017)

Brandin, J., Liliedahl, T.: Unit operations for production of clean hydrogen-rich synthesis gas from gasified biomass. Biomass Bioener. 35, 8–15 (2011)

Einvall, J., Parsland, Ch., Benito, P., Basile, F., Brandin, J.: High temperature water-gas shift step in the production of clean hydrogen rich synthesis gas from gasified biomass. Biomass Bioener. 35, 123–131 (2011)

Luo, S., Xiao, B., Hu, Zh., Liu, Sh., Guo, X., He, M.: Hydrogen-rich gas from catalytic steam gasification of biomass in a fixed bed reactor: influence of temperature and steam on gasification performance. Int. J. Hydrog. Energy 34, 2191–2194 (2009)

Rapagna, S., Provendier, H., Petit, C., Kiennemann, A., Foscolo, P.U.: Development of catalysts suitable for hydrogen or syn-gas production from biomass gasi cation. Biomass Bioener. 22, 377–388 (2002)

Ghasemzadeh, K., Khosravi, M., Sadati Tilebon, S.M., Aghaeinejad-Meybodi, A., Basile, A.: Theoretical evaluation of PdeAg membrane reactor performance during biomass steam gasification for hydrogen production using CFD method. Int. J. Hydrog. Energy 43(26), 11719–11730 (2018)

Secer, A., Kucet, N., Fakı, E., Hasanoglu, A.: Comparison of coegasification efficiencies of coal, lignocellulosic biomass and biomass hydrolysate for high yield hydrogen production. Int. J. Hydrog. Energy 43(46), 21269–21278 (2018)

Guizani, C., Louisnard, O., Escudero Sanz, F.J., Salvador, S.: Gasification of woody biomass under high heating rate conditions in pure CO2: experiments and modelling. Biomass Bioener. 83, 169–182 (2015)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amani, A., Akhlaghian, F. Hydrogen production from co-gasification of Çan lignite and sorghum biomass in a fixed-bed gasifier: CFD modeling. Int J Energy Environ Eng 13, 295–304 (2022). https://doi.org/10.1007/s40095-021-00423-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-021-00423-y