Abstract

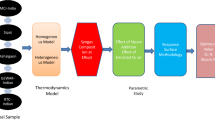

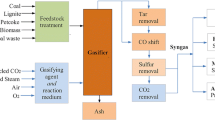

The present research work proposes an optimization procedure using Taguchi method and utility concept with the main objective of maximizing the calorific value of syngas with lower CO2 yield during coal gasification process using thermodynamic equilibrium model based on stoichiometric approach. After validating the model with experimental results, the effect of air supply and steam supply on output gas composition and temperature were analyzed in detail. For the purpose of optimization, six control variables at three levels consisting of coal properties, oxidant properties, and reaction properties are considered for optimization of objective functions. The trial runs for Taguchi analysis were carried out using L27 orthogonal array and the concept of signal-to-noise ratio was used to optimize the process. Taguchi method produced two sets of levels of the control variables, one for maximum calorific value of 3.59 MJ/m3 and another set for minimum CO2 yield of 6.25%. To obtain a common set of control variable levels, utility concept has been implemented for optimization of maximum calorific value with low CO2 yield simultaneously. Among the control variables considered, air supply, steam supply, and H/C ratio of coal are found to be the most influencing parameters. It is observed that the calorific value and CO2 yield calculated from the utility concept differ by 3.34% and 2.30%, respectively, compared to the values calculated by the Taguchi method.

Similar content being viewed by others

Data availability

Data available on request from authors.

References

Madurai Elavarasan, R., Afridhis, S., Vijayaraghavan, R.R., Subramaniam, U., Nurunnabi, M., Ahmad, T., Zhang, D.: SWOT analysis: a framework for comprehensive evaluation of drivers and barriers for renewable energy development in significant countries. Energy Rep. 6, 1838–1864 (2020). https://doi.org/10.1016/j.egyr.2020.07.020

Ahmad, T., Zhang, D.: A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 6, 1973–1991 (2020). https://doi.org/10.1016/j.egyr.2020.07.020

Haque, M.I.: Oil price shocks and energy consumption in GCC countries: a system-GMM approach. Environ. Dev. Sustain. (2020). https://doi.org/10.1007/s10668-020-01027-y

Behera, B.K., Varma, A.: Thermal conversions of biomass. In: Bioenergy for Sustainability and Security, pp. 301–369. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-96538-3_6

Karim, R.: Numerical modelling of fixed and moving bed biomass combustion under air and oxy-fuel conditions. Phd thesis, Swinburne University of Technology, Australia (2018)

Munir, M.T., Mardon, I., Al-Zuhair, S., Shawabkeh, A., Saqib, N.U.: Plasma gasification of municipal solid waste for waste-to-value processing. Renew. Sustain. Energy Rev. 116, 109461 (2019). https://doi.org/10.1016/j.rser.2019.109461

Veksha, A., Giannis, A., Yuan, G., Tng, J., Chan, W.P., Chang, V.W.C., Lisak, G., Lim, T.T.: Distribution and modeling of tar compounds produced during downdraft gasification of municipal solid waste. Renew. Energy. 136, 1294–1303 (2019). https://doi.org/10.1016/j.renene.2018.09.104

Jarungthammachote, S., Dutta, A.: Equilibrium modeling of gasification : Gibbs free energy minimization approach and its application to spouted bed and spout-fluid bed gasifiers. Energy. Convers. Manag. 49, 1345–1356 (2008). https://doi.org/10.1016/j.enconman.2008.01.006

Shabbar, S., Janajreh, I.: Thermodynamic equilibrium analysis of coal gasification using Gibbs energy minimization method. Energy Convers. Manag. 65, 755–763 (2013). https://doi.org/10.1016/j.enconman.2012.02.032

Zainal, Z.A., Ali, R., Lean, C.H., Seetharamu, K.N.: Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 42, 1499–1515 (2001). https://doi.org/10.1016/S0196-8904(00)00078-9

Barman, N.S., Ghosh, S., De, S.: Gasification of biomass in a fixed bed downdraft gasifier—a realistic model including tar. Bioresour. Technol. 107, 505–511 (2012). https://doi.org/10.1016/j.biortech.2011.12.124

La Villetta, M., Costa, M., Massarotti, N.: Modelling approaches to biomass gasification: a review with emphasis on the stoichiometric method. Renew. Sustain. Energy Rev. 74, 71–88 (2017). https://doi.org/10.1016/j.rser.2017.02.027

Silva, I.P., Lima, R.M.A., Silva, G.F., Ruzene, D.S., Silva, D.P.: Thermodynamic equilibrium model based on stoichiometric method for biomass gasification: a review of model modifications. Renew. Sustain. Energy Rev. 114, 109305 (2019). https://doi.org/10.1016/j.rser.2019.109305

Lin, S., Wang, Y., Suzuki, Y.: Effect of coal rank on steam gasification of coal/CaO mixtures. Energy Fuels 21, 2763–2768 (2007). https://doi.org/10.1021/ef070116h

Żogała, A.: Equilibrium simulations of coal gasification—factors affecting syngas composition. J. Sustain. Min. 13, 30–38 (2014). https://doi.org/10.7424/jsm140205

Zhang, L., Huang, J., Fang, Y., Wang, Y.: Gasification reactivity and kinetics of typical Chinese anthracite chars with steam and CO2. Energy Fuels 20, 1201–1210 (2006). https://doi.org/10.1021/ef050343o

Sharma, A.K.: Equilibrium and kinetic modeling of char reduction reactions in a downdraft biomass gasifier: a comparison. Sol. Energy. 82, 918–928 (2008). https://doi.org/10.1016/j.solener.2008.03.004

Costa, M., Massarotti, N., Cappuccio, G., Chang, C.T., Shiue, A., Lin, C.J., Wang, Y.T.: Modeling of syngas production from biomass energy resources available in taiwan. Chem. Eng. Trans. 37, 343–348 (2014). https://doi.org/10.3303/CET1437058

Melgar, A., Pérez, J.F., Laget, H., Horillo, A.: Thermochemical equilibrium modelling of a gasifying process. Energy Convers. Manag. 48, 59–67 (2007). https://doi.org/10.1016/j.enconman.2006.05.004

Ramanan, M.V., Lakshmanan, E., Sethumadhavan, R.: Modeling and experimental validation of cashew nut shell char gasification adopting chemical equilibrium approach. Energy Fuels. 22, 2070–2078 (2008). https://doi.org/10.1590/S0104-66322008000300016

Sharma, A.K.: Equilibrium modeling of global reduction reactions for a downdraft (biomass) gasifier. Energy Convers. Manag. 49, 832–842 (2008). https://doi.org/10.1016/j.enconman.2007.06.025

Ptasinski, K.J., Prins, M.J., Pierik, A.: Exergetic evaluation of biomass gasification. Energy 32, 568–574 (2007). https://doi.org/10.1016/j.energy.2006.06.024

Prins, M.J., Ptasinski, K.J., Janssen, F.J.J.G.: From coal to biomass gasification: comparison of thermodynamic efficiency. Energy 32, 1248–1259 (2007). https://doi.org/10.1016/j.energy.2006.07.017

Eftekhari, A.A., Van Der Kooi, H., Bruining, H.: Exergy analysis of underground coal gasification with simultaneous storage of carbon dioxide. Energy 45, 729–745 (2012). https://doi.org/10.1016/j.energy.2012.07.019

Chen, W.H., Chen, C.J., Hung, C.I.: Taguchi approach for co-gasification optimization of torrefied biomass and coal. Bioresour. Technol. 144, 615–622 (2013). https://doi.org/10.1016/j.biortech.2013.07.016

Chen, C.J., Hung, C.I.: Optimization of co-gasification process in an entrained-flow gasifier using the Taguchi method. J. Therm. Sci. Technol. 8, 190–208 (2013). https://doi.org/10.1299/jtst.8.190

Guo, S., Zhou, X., Song, S., Mei, Y., Zhao, J., Fang, Y.: Optimization of leaching conditions for removing sodium from sodium-rich coals by orthogonal experiments. Fuel 208, 499–507 (2017). https://doi.org/10.1016/j.fuel.2017.07.032

Syed, S., Janajreh, I., Ghenai, C.: Thermodynamics equilibrium analysis within the entrained flow gasifier environment. Int. J. Therm. Environ. Eng. 4, 47–54 (2011). https://doi.org/10.5383/ijtee.04.01.007

Jarungthammachote, S., Dutta, A.: Thermodynamic equilibrium model and second law analysis of a downdraſt waste gasifier. Energy 32, 1660–1669 (2007). https://doi.org/10.1016/j.energy.2007.01.010

Jarungthammachote, S., Dutta, A.: Thermodynamic equilibrium model and second law analysis of a downdraft waste gasifier. Energy. 32, 1660–1669 (2007). https://doi.org/10.1016/j.energy.2007.01.010

Chase, M.: NIST-JANAF Thermochemical Tables, 4th Edition, http://www.aip.org/pubs/books/jpcrd_books.html (1998)

Thring, M.W., Meredith, W.: The Science of Flames and Furnaces. Chapman & Hall, London (1962)

Phadke, M.S.: Quality Engineering Using Robust Design. Prentice Hall PTR, Upper Saddle River (1995)

Pandey, N., Murugesan, K., Thomas, H.R.: Optimization of ground heat exchangers for space heating and cooling applications using Taguchi method and utility concept. Appl. Energy. 190, 421–438 (2017). https://doi.org/10.1016/j.apenergy.2016.12.154

Kishore, R.A., Sanghadasa, M., Priya, S.: Optimization of segmented thermoelectric generator using Taguchi and ANOVA techniques. Sci. Rep. 7, 1–15 (2017). https://doi.org/10.1038/s41598-017-16372-8

Harris, L.N.: Taguchi techniques for quality engineering, Philip J. Ross, Mcgraw-hill book company, 1988. Qual. Reliab. Eng. Int. 5, 249 (1989). https://doi.org/10.1002/qre.4680050312

Sivasakthivel, T., Murugesan, K., Thomas, H.R.: Optimization of operating parameters of ground source heat pump system for space heating and cooling by Taguchi method and utility concept. Appl. Energy. 116, 76–85 (2014). https://doi.org/10.1016/j.apenergy.2013.10.065

Dubey, A.K.: Multi-response optimization of electro-chemical honing using utility-based Taguchi approach. Int. J. Adv. Manuf. Technol. 41, 749–759 (2009). https://doi.org/10.1007/s00170-008-1525-2

Pandey, S., Baral, B., Karki, S., Upreti, A.: Prediction of syngas composition from biomass gasification using thermodynamics equilibrium model. Rentech Symp. Compend. 3, 5–8 (2013)

Zagorščak, R., An, N., Palange, R., Green, M., Krishnan, M., Thomas, H.R.: Underground coal gasification—a numerical approach to study the formation of syngas and its reactive transport in the surrounding strata. Fuel 253, 349–360 (2019). https://doi.org/10.1016/j.fuel.2019.04.164

Patel, V.R., Upadhyay, D.S., Patel, R.N.: Gasification of lignite in a fixed bed reactor: Influence of particle size on performance of downdraft gasifier. Energy. 78, 323–332 (2014). https://doi.org/10.1016/j.energy.2014.10.017

Singh, H., Kumar, P.: Optimizing multi-machining characteristics through Taguchi’s approach and utility concept. J. Manuf. Technol. Manag. 17, 255–274 (2006). https://doi.org/10.1108/17410380610642304

Acknowledgements

The first author would like to thank the MHRD, Government of India, for providing the financial support for pursuing Doctoral studies at IIT Roorkee, Roorkee, India.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

RP: modeling and simulation, analysis of results, and writing—original draft preparation. MK: analysis of results, and writing—reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Palange, R., Krishnan, M. Coal gasification process optimization for maximum calorific value and minimum CO2 emission using Taguchi method and utility concept. Int J Energy Environ Eng 12, 335–351 (2021). https://doi.org/10.1007/s40095-020-00377-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-020-00377-7