Abstract

A scheme has been proposed, modeled and simulated to show an improved system efficiency, battery life and payback period of a 340 kWp peak power grid interactive solar photovoltaic system. In this case, a conventional solar photovoltaic system capable to fulfill 66% energy demands has been modified to meet complete energy demands without an increase in system’s photovoltaic capacity. It has been shown via modelling and simulation on PVSyst that using direct current appliances instead of alternating current appliances, initial power demands are reduced by 58% and conversion losses (DC–AC–DC) of 9.6% are eliminated. These modifications result in an overall increase in the system’s performance ratio from 73.8 to 83.4%, with an increase in energy production from 469.6 to 557.9 MWh. As an outcome, battery life is increased by 1200 duty cycles as the depth of discharge is reduced from 35 to 26%.

Similar content being viewed by others

Introduction

Evidently, over the last decade, a sustained and progressive growth in the development and adoption of solar systems has been observed [1] and relatively an increasing public interest and the advancement in the efficient and cost-effective solar technology as concerns over grid failure and the depletion natural resources have intensified [2]. Solar photovoltaic (PV) has emerged as a potential resource for addition and supplementation of grid power capacity [3, 4]. Net-metered PV power systems [5], which have dominated on-site renewable energy supply in the buildings sector, are a direct current (DC) power source, as are batteries, which are the dominant energy storage technology used with such systems [6]. A number of factors are driving the recent shift in the interest of using DC power from solar electric systems in its DC form directly [7], to power electricity loads in buildings, rather than converting it to alternating current (AC) first, as is the current practice [8].

Technology advancements have profoundly triggered an important factor that favors the use of DC, the reason being that the electric appliances that operate internally on DC are increasing more rapidly, and the fact that these new DC-internal technologies tend to be more efficient than their AC counterparts especially fans and light-emitting diodes (LEDs) [9]. Technically, this supports the idea that energy savings could be achieved by directly coupling DC power sources with DC appliances [10], thus avoiding DC–AC–DC power conversion losses and resultantly, an accompanied efficiency increase can be achieved [11]. Recent demonstrations experimented with commercial data centers have shown that considerable energy savings can be achieved with DC power distribution supplied directly to DC loads, rather than utilizing AC power [12, 13].

In support of the undersigned research paper, a real-time-based modeling of a PV solar-powered system is configured, which is an integral part for the development of a complete grid interactive solar photovoltaic (GISP) simulation model where converter losses have been minimized and performance ratio of the PV system has been maximized using DC as a primary source. Technically, the process is achieved by integrating the DC power directly with the load keeping it independent from the DC–AC converters. In this case, the relative energy savings of ‘direct-DC’ power for loads which have primarily day time usage only are also assessed. Among several PV modelling software [14, 15], one of the most common is PVSyst (See website: http://www.pvsyst.com). Over the years, this software application has been widely used for PV modelling [16] and sizing the components of the PV system [17, 18] or PV system assessment [19]. In connection with this paper, a solar power system is modeled and simulated in PVSyst. The results obtained after performing the simulations clearly show that the system performance ratio has improved and the overall cost of the installed system has reduced after eliminating DC–AC converters.

System description

Schematic diagram for existing system

As a demonstration, the schematic diagram for the system under consideration is shown in Fig. 1. For the operational purpose, inverter is utilized as a major component of the system to run the connected load by converting DC energy from PV modules to AC energy. During cloudy days or at night, the inverter uses grid to run the load and at the same time charging the batteries. On account of frequent load shedding and worse grid conditions (frequent low grid voltage, electrical transients and surges), AC–DC–AC conversion is used. Consequently, this also ensures the real-time energy sharing between the grid and the PV plant at the same time improving the power quality at output.

Existing system components

The complete PV system consists of solar PV modules (DC power generator), inverters (DC–AC conversion) with built-in charge controller (DC–DC conversion) and batteries for energy storage purpose. The technical specifications of different system components being used which include Yingli Solar, YL255P-29B YGE 60 cell 40 mm series PV modules, Zigor HIT3C Inverters and SOPzS lead acid batteries [20] are shown in Tables 1, 2 and 3, respectively.

Schematic diagram of the proposed system

The part of the schematic diagram marked in Fig. 2 highlights the improvement being proposed to the existing solar system increasing system efficiency by ensuring maximum direct utilization of DC power generated by PV modules. Power converter losses occurring due to DC to AC conversion are minimized, enhancing the overall performance ratio of the solar plant.

Proposed system components

Table 4 below shows the modifications made to the existing system and the additional components added altogether.

Load profile

Existing system

The complete load demands for the facility are shown in Table 5. The total accumulated load of the facility is 425 kW.

Table 6 shows only the essential load estimating around 280 kW has been connected and supported by solar system. While segregating the 280 kW solar connected load, the operational hours of 220 kW day-time load are from 08:00 to 15:00 h, whereas the working hours of 60 kW load operating during night are from 16:00 to 08:00 h.

Table 7 provides details of the load shedding, sunshine and grid availability hours in a single day. Considering the present local scenario, there are approximately 6 h of load shedding in one single complete day. Taking into account multiple factors which include frequent grid failures or non-availability occurring at random times during the day and availability of 8 h of daily sunshine, all the calculations for the battery usage are made for only 10 h of grid utilization. Since the main objective is to reduce dependency on National Grid, the system has been designed not to use grid during the day time and also ensuring maximum 35% Depth of Discharge (DOD) for the batteries at the same time.

Proposed system

Retrofitting concept has been implemented for the proposed system, while replacing AC load appliances of the complete facility with energy-efficient DC load appliances, i.e. lighting and fan load, which would reduce the overall load by 50%, i.e. from 350 to 175 kW. The AC inductive load estimated around 75 kW remains independent. The load demands have been distinctly altered for the proposed system as shown in Table 8. The load operated during the day time is reduced to 210 kW (accumulating 135 kW of lighting and fans load through retrofitting of AC appliances with DC appliances and 75 kW of inductive load) which operates from 08:00 to 15:00 h daily and the load operated during night time is reduced to 40 kW having working hours from 16:00 to 08:00 h while completely eliminating the use of diesel generator.

Following equation (Eq. 1) is applied to calculate the depth of discharge (DOD) for the batteries in the proposed system:

where DOD is the depth of discharge, W load in watts, B battery backup hours, V system voltage, and AH is the capacity of battery.

The number of PV modules required to charge batteries during the day is calculated using Eq. 2. This would help to determine the most appropriate value for the DOD of the batteries for a given Solar PV system:

where N is the no. of panels required, E efficiency of solar PV module at NOCT (nominal operating cell temperature), S number of sun shine hours, and P panel wattage at NOCT.

Efficiency of the solar PV module is considered at NOCT specifications mentioned, which signifies the realistic value of the PV module performance in real-time conditions, whereas SH are taken as the yearly average sunshine hours present in Pakistan in one single day. In the proposed system, DOD is reduced from 35 to 26% which specifically indicates that the battery usage is reduced.

Battery discharge behaviour

Existing system

The overall energy production and consumption along with the detailed battery discharge statistics for consecutive 3 days of the existing solar system is given in Table 9. Grid is used for 10 h per day to meet the complete energy demands of the connected load on solar system. The maximum battery DOD for the existing system is 35%.

The graph in Fig. 3 shows the energy produced and consumed by the existing system in a single day. It explains the hourly status of actual energy generation from the Solar Array, the optimum energy consumption (hours) and energy variance to/from battery.

The graph in Fig. 4 shows the maximum DOD achieved by the battery bank. It demonstrates the hourly status of percentage discharge of the battery bank based on a 24-h cycle of system operation. The graph shows that the battery is being used up to 35% depth of discharge. The operational timing has been assumed based on standard operations (working hours) as mentioned above.

Figure 5 illustrates the hourly status of the battery bank available and the battery bank consumed based on the 24-h cycle of system operation for the existing system. It shows that the battery bank is still 65% full.

Proposed system

The overall energy production and consumption along with the detailed battery discharge statistics for 3 consecutive days of the proposed solar system is given in Table 10. It can be clearly seen that the grid usage has been reduced to 6 h per day to meet the complete energy demands of the connected load on solar system. The maximum battery DOD for the proposed system also reduces to 26% ensuring increase in battery life.

The graph in Fig. 6 demonstrates the energy produced and consumed by the proposed system in a single day. It explains the hourly status of actual energy generation from the Solar Array, the optimum energy consumption (hours) and energy variation to/from battery.

The graph in Fig. 7 confirms the maximum DOD achieved by the battery bank. It demonstrates the hourly status of percentage discharge of the battery bank based on a 24-h cycle of system operation. The graph shows that the battery is being used up to 26% depth of discharge. The operational timing has been assumed based on standard operations (working hours) as mentioned above.

Figure 8 shows the hourly status of the battery bank available and the battery bank consumed based on the 24-h cycle of system operation for the proposed system. It shows that the battery bank is still 74% full.

System simulation

Figure 9 shows the flow diagram for the proposed system. These parameters have been used to run the simulations for the proposed system in the PVSyst software. The regulator has the tendency to charge the batteries and run the load from both PV array, grid and generator, thus ensuring the reliable working of the system and increasing the robustness of the overall system [21]. The remaining AC inductive load runs on the already-installed inverters.

PVsyst software V5.55 is used to run the computer simulations to evaluate the performance of the solar power plant.

Existing system

While running the simulations, the solar modules are placed at the south facing with 0° angle of azimuth. The modules are tilted at an angle of 30° with the horizontal. The mounting structure is kept fixed which significantly reduces the initial and maintenance cost of the overall solar power plant as it eliminates the rotating and moving parts. Due to fixed structure, best average tilt angle of 30° is used which can yield maximum production throughout the year [22]. Figure 10 shows the simulation results of normalized production and performance ratio for the existing system. The PV plant is producing 3.79 kWh of energy per peak watt per day on average basis in a year working at performance ratio of 73.8% over the year including cloudy, foggy and rainy days.

Table 11 shows the energy produced per month by the PV plant for its first-year operation at different irradiation and temperature levels. Solar system is producing 469.56 MWh of useful energy after calculating all the losses based on average horizontal global irradiance of 1720 kWh/m2 and ambient temperature of 24.12 °C in 1 year.

Figure 11 is the detailed analysis of the losses present in the existing solar system. Only 35% of energy from the PV modules is directly used whereas 65% of energy is used after being accumulated in batteries. This accounts for the significant losses in the system up to 8.6% in the form of battery efficiency loss, gassing current (electrolyte dissociation) and battery self-discharge currents.

Proposed system

Figure 12 shows the simulation results of normalized production and performance ratio for the proposed system. The PV plant is producing 4.5 kWh of energy per peak watt per day on average basis in a year working at performance ratio of 83.4% over the year including cloudy, foggy and rainy days.

Table 12 shows the energy produced per month by the PV plant for its first-year operation at different irradiation and temperature levels. Solar system is producing 557.90 MWh of useful energy after calculating all the losses based on average horizontal global irradiance of 1720 kWh/m2 and ambient temperature of 24.12 °C in 1 year.

Figure 14 shows the detailed analysis of the losses present in the proposed solar system. It shows that after retrofitting of AC appliances with DC appliances the significant losses associated with the batteries in the form of efficiency loss, gassing current (electrolyte dissociation) and battery self-discharge current have been eliminated resulting in an increase in performance ratio and energy generation of the system.

The loss diagram for the PV system after modifications and upgrading the existing system shows that 557.9 MWh is the useful energy available after calculating all the losses. There is 88.9 MWh increase in the units produced. The loss diagram in Fig. 13 shows that the overall battery efficiency losses for the complete system are 9.6% out of which 3.1% are due to gassing current which is also defined as electrolytic dissociation and 0.2% due to battery self-discharge current [23]. These losses due to battery DC–AC conversion have been eliminated in the new system resulting in improved efficiency by 9.6%.

Results and discussion

The performance ratio improvement and energy production attained for each respective month for the given irradiance data for both existing and proposed solar system are given in Table 13. The existing solar system working on performance ratio of 73.80% produces 469.56 kWh units and the proposed system working on 83.40% efficiency can produce 557.9 MWh of energy in one complete year.

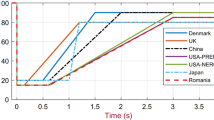

The month-wise performance ratio trend for the first year of the existing and the proposed system can be observed in Fig. 14. The trend shows an increase of 9.6% over the year.

The increased production of energy in the new system due to increased efficiency of the system is presented in Fig. 15.

The computer simulation results show that efficiency of the system can be improved by 9.6% for its day time usage when solar is being directly utilized by the load. These 9.6% are the minimum losses which are associated with DC–AC–DC convertor losses. These losses can be minimized by direct utilization of DC power. As a result, the overall performance ratio of the system can be increased from 73.8 to 83.4%. For the remaining AC load of 75 kW, the normal DC–AC conversion is applicable. The solar modules installed can produce 557.9 MWh of electricity units annually, whereas existing system produces only 469 MWh. The system which previously provides power to only 66.66% of total load can now run the complete 100% load at the same time reducing daily grid usage from 10 to 6 h and completely eliminating the use of diesel generator. The battery life is also enhanced as the number of battery cycles increases from 3800 to 5000 due to reduction of DOD from 35 to 26%.

Conclusions

By replacing traditional AC appliances with energy-efficient DC appliances in the existing solar system, load is reduced by 58% of total load, i.e. from 425 to 250 kW. Further, by ensuring direct utilization of DC power to run DC appliances, DC–AC–DC power converter losses for 70% load are reduced by 9.6%. For the remaining 30% load, the efficiency stays the same as a conventional hybrid system. Hence, efficiency improvement for 70% load results in a much quicker payback time due to improvement of performance ratio to 83.4% for the overall system. 340 kWp of PV which previously provide power to only 66.66% load can now run the 100% load. Further, implementing this technique ensures uninterrupted power supply to the complete load at much lesser rate. It also ensures the use of generator to the minimum extent. The overall life of the batteries is also prolonged due to direct utilization feature resulting in increased duty cycles, reduced operation and maintenance expense over the plant life cycle of 25 years.

References

Sampaio, P.G.V., González, M.O.A.: Renew. Sustain. Energy Rev. 74, 590 (2017)

Manju, S., Sagar, N.: Renew. Sustain. Energy Rev. 70, 298 (2017)

Mueller, S.: Next Generation Wind and Solar Power, from Cost to Value. International Energy Agency, Paris (2016)

Murphy, F., McDonnell, K.: MDPI Sustain. 9, 302 (2017)

Darghouth, N.R., Wiser, R.H., Barbose, G., Mills, A.D.: Appl. Energy 162, 713 (2016)

Kempener, R., Borden, E.: Battery Storage for Renewables: Market Status and Technology Outlook, p. 32. International Renewable Energy Agency, Abu Dhabi (2015)

Rauf, S., Wahab, A., Rizwan, M., Khan, N.: In application of dc-grid for efficient use of solar PV system in smart grid. In: Shakshuki, E. (ed.) Procedia Computer Science, Proceedings of the 6th International Conference on Sustainable Energy Information Technology, Madrid, 23–26 May 2016, pp. 902–906 (2016)

Obi, M., Bass, R.: Renew. Sustain. Energy Rev. 58, 1082 (2016)

Lucía, Ó., Cvetkovic, I., Sarnago, H., Boroyevich, D., Mattavelli, P., Lee, F.C.: IEEE J. Emerg. Sel. Top. Power Electron. 1, 315 (2013)

Vossos, V., Garbesi, K., Shen, H.: Energy Build. 68, 223 (2014)

Kim, Youngjin: Energies 10, 427 (2017)

Garbesi, K., Vossos, V., Shen, H., Taylor, J., Burch, G.: Catalog of DC Appliances and Power Systems. Berkeley National Laboratory in association with the US Department of Energy, Berkeley (2011)

Dastgeer, F., Gelani, H.E.: Energy Build. 138, 648 (2017)

Crawley, D.B., Hand, J.W., Kummert, M., Griffith, B.T.: Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 43(4), 661–673 (2008)

Sinha, S., Chandel, S.S.: Review of software tools for hybrid renewable energy systems. Renew. Sustain. Energy Rev. 32, 192–205 (2014)

Sauer, K.J., Roessler, T., Hansen, C.W.: Modeling the irradiance and temperature dependence of photovoltaic modules in PVsyst. IEEE J. Photovolt. 5(1), 152–158 (2015)

Faranda, R.S., Hafezi, H., Leva, S., Mussetta, M., Ogliari, E.: The optimum PV plant for a given solar DC/AC converter. Energies 8(6), 4853–4870 (2015)

Dolara, A., et al.: Performance analysis of a single-axis tracking PV system. IEEE J. Photovolt. 2(4), 524–531 (2012)

Mermoud, A., Lejeune, T.: Performance assessment of a simulation model for PV modules of any available technology. 25th Eur. PV Sol. Energy Conf., pp. 6–10 (2010)

Manimekalai, P., Harikumar, R., Raghavan, S.: Int. J. Comput. Appl. 82, 29 (2013)

Cetin, E., Yilanci, A., Ozturk, H.K., Colak, M., Kasikci, I., Iplikci, S.: Energy Build. 42, 1344 (2010)

Perez, R., Ineichen, P., Seals, R.: Solar Energy 44, 271 (1990)

Moslehi, K.: IEEE Trans. 1(1), 57 (2014)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that the manuscript has not been published before nor submitted to another journal for the consideration of publication. It is the sole work and property of all the mentioned authors and there is no conflict of interest with anyone.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to urisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

Real-time energy generation data of existing system for one complete year from January 2016 to December 2016 is given below (Table 14):

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Aslam, Z., Shahid, H. & Mahmood, Z. Modelling and analysis of an improved scheme for a 340 kWp grid interactive PV system in Pakistan to enhance performance ratio and battery life. Int J Energy Environ Eng 9, 187–199 (2018). https://doi.org/10.1007/s40095-018-0261-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-018-0261-0