Abstract

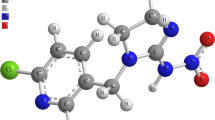

The zero-valent iron (ZVI) impregnated MCM-48 (Fe-MCM-48) as a new reagent was used to dechloronation of 2,4-dichlorophenol (2,4-DCP) pollutant. The Fe-MCM-48 was prepared by a grinding method as a solvent-free procedure. The X-ray diffraction patterns, SEM images and EDX spectra were applied to characterize the Fe-MCM-48 regent. The impregnation of ZVI nanoparticles occurred in the channels of mesoprous MCM-48. The zero-valent iron amount was 23 ± 2 % in Fe-MCM-48 that was confirmed by EDX analysis. The dechloronation of 2,4-dichlorophenol (>95 %) was optimized at pH 4 and 150 mg/L of Fe-MCM-48. The dechloronation reaction showed the pseudo first-order kinetic based on the initial concentration of 2,4-DCP in range of 100–400 mg/L. The increasing of available sites of Fe-MCM-48 versus dispersed zero-valent iron particles showed an advantage for new reagent in dechloronation reaction. The reusability of proposed reagent showed an efficiency of 95–55 % for a four-cycle of dechloronation reaction.

Similar content being viewed by others

Introduction

Today the problems and conditions of drinking water are one of the major problems in most countries. Because of extended droughts, population growth, more stringent health-based regulations, and competing demands from a variety of users, the need for clean water and thus the treatment of ordinary water is a fundamental requirement for the world [1]. Clean water, namely the water that is free of toxic chemicals and pathogens, is essential to human health [2, 3].

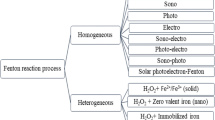

Metal nanoparticles, such as iron, zinc, nickel, etc. have many advantages for remediation of contamination with chlorinated organic pollutants. These advantages are the small particle size, large specific surface area, excellent adsorption, and high reduction reactivity [1–3]. Among metal nanoparticles, zero-valent iron (ZVI) nanoparticles has been used for the treatment of environmental pollution [4, 5]. The ZVI is a very effective reducing agent for dehalogenation and can catalytically reduce various halogenated organics into non- or low-toxic compounds, including the persistent organic pollutants chlorohydrocarbons, chloroaromatics, chlorophenol, organochloride pesticides, and polybrominated diphenyl ethers [6–11].

Mesoporous silicas have several advantages such as uniform pore size, high surface area, and large pore volume. They have been utilized in many fields of science and engineering, including catalysis, adsorption, and separation [12]. The mesoporous silicas formed by different templating agent exhibit different pore size, pore structure, and amount of surface hydroxyl group [13]. The mesoporous silicas can be applied for catalytic conversion or adsorptive separation of bulky molecules. The mesoporous molecular sieves can also be used as host materials for specific molecules like porphyrins or other transition metal complexes [14, 15]. A main drawback of these materials is their inactive chemical composition [16].

MCM-48 has a cubic array with a three-dimensional pore network and shows a high surface area and hydrothermal stability. It is a member of the M41S mesoporous silica family [17]. This mesoporous silica is used in many applications, including adsorption, ion exchange, catalysis, etc. [18]. The impregnations of MCM-48 with transition metals such as Ce, Zn, Cd and others are reported in many papers [19].

In this research, the impregnation of zero-valent iron in MCM-48 by grinding as a free-solvent, simple, and efficient method is reported. The NaBH4 as a reductant is used to reduce of ferric ions to zero-valent iron nanoparticles. The structure of Fe-MCM-48 is evaluated by XRD, SEM, and EDX methods. The new reagent of Fe-MCM-48 with high surface area is used to dechloronation of 2,4-dichlorophenol (2,4-DCP).

Experimental

Synthesis and characterization of Fe and Fe-MCM-48

All of the materials were of highest purity. All solutions were prepared with double distilled water. In synthesis of MCM-48, CTAB was dissolved in deionized water. Then, sodium hydroxide and tetraethyl orthosilicate (TEOS) were added [17]. The molar composition of the gel was 1 M TEOS: 0.25 M Na2O: 0.65 M CTAB: 0.62 M H2O. The solution was stirred for about 1 h and then transferred into a polypropylene bottle and heated up to 100 °C for 3 days. The product was filtered, washed with water, and dried in air at ambient temperature. The dried product was finally calcind at 550 °C for 6 h [17].

In a typical grinding procedure for an effective incorporation of metals into channel of mesoporous materials, 1.2076 g of FeCl3·6H2O and 0.75 g of synthesized MCM-48 were taken in a mortar and ground well at room temperature. A NaBH4 solution (0.1 mol/L) was added drop by drop to prepared solid sample at room temperature and N2 atmosphere. The Fe3+ ions were reduced to Fe0 particles by NaBH4 reductant [20].

The particles of Fe-MCM-48 were removed, washed with diluted HCl, ethanol, water and acetone, and then dried at temperature of 50 °C for 3–4 h [9]. The weight percent of Fe0 particles was 25 % in obtained Fe-MCM-48.

A Diffractometer Bruker D8ADVANCE Germany with anode of Cu ( = 1.5406 Å of Cu Kα) and filter of Ni was applied for the record of X-ray diffraction (XRD) patterns of mesoporous MCM-48 and Fe-MCM-48 in the 2 ranges of 0.5°–7° and 5°–70°. The morphology and composition of Fe-MCM-48 were evaluated by SEM-EDX informations. The SEM images and EDX spectra were obtained by a Philips XL30 scanning electron microscope. N2 adsorption isotherms of prepared photocatalysts were obtained by the B.E.T. method using nitrogen as an adsorption gas at 77 K using a Belsorp Mini Π instrument. Samples were out gassed at 300 °C for 4 h prior to surface area measurements.

Dechlorination of 2,4-dichlorophenol

Batch experiments for dechloronation of 2,4-DCP were performed in 15-mL bottles. 0.5–2.0 mg Fe-MCM-48 was loaded into bottles containing 10 mL of aqueous solution of 2,4-DCP (100–400 mg/L). The bottles were sealed with rubber plugs and placed on a TZ-2EH rotary shaker (100 r/min) during the entire experiment period (2–8 h). 2,4-DCP and its intermediate products were quantified with an Agilent 1100 HPLC equipped with a C18 column and a L-4000 UV–Vis detector. All samples were filtrated with 0.45-μm filter film. The degradation efficiency (%D) was calculated from initial concentration (Co) and residual concentration (Ct) of 2,4-DCP (%D = [1 − (Ct/Co)] × 100). The concentration of 2,4-DCP was obtained by measuring of surface area of HPLC peak. In order to investigate the adsorption of 2,4-DCP on heterogeneous reagent surface, the residual reagent in filtration step was washed with ethanol, water, and acetone solution and the obtained sample analyzed by HPLC method. The result showed that the amount of adsorbed 2,4-DCP molecules (that not dechloronated in the reaction) was <5 % versus to initial concentration.

Results and discussion

Characterization of Fe and Fe-MCM-48

The XRD patterns, SEM images, and EDX spectra of prepared samples are used to characterize the prepared Fe-MCM-48. The XRD patterns of ZVI, MCM-48, and Fe-MCM-48 at small-angle and wide-angle are shown in Figs. 1, 2 and 3. The existence of a diffraction peak at 2 = 45º shows the formation of zero-valent iron (ZVI) nanoparticles as per JCPDS No. 06-0696 (Fig. 1) [21]. The cubic ordered structure of MCM-48 is confirmed by XRD pattern (Fig. 2) [16, 17]. The most intense diffraction peak (211) appears at 2 = 2.3º. Other low intense diffraction peaks of higher order appear at 2 = 3º–6º. Also, the diffraction peak of ZVI in the wide-angle XRD pattern of Fe-MCM-48 is observed at 2 = 45º which obviously shows the content of ZVI in the channel of mesoprous MCM-48 [19].

The SEM images of MCM-48 and impregnated MCM-48 (Fe-MCM-48) are shown in Fig. 4a, b, respectively. The particles with size 300–800 nm are MCM-48 while the ZVI nanoparticles are seen in dimensions of 50–70 nm. Figure 5 shows the EDX spectra of MCM-48 and Fe-MCM-48. The existence of iron in impregnated MCM-48 is obvious from the EDX spectra. The EDX spectra show high percentage of silicon and oxygen which are the main constituents of the MCM-48. The EDX spectra indicates that the only reducing agent present in the substrate is ZVI, which has the capability of dechlorination of 2,4-DCP.

The atomic absorbance spectrophotometery is used to determine the content of ZVI in impregnated MCM-48. The results reconfirmed the percentage of iron to be around 23 ± 2 %.

Dechloronation of 2,4-DCP

The effect of pH on the dechloronation of 2,4-DCP is studied in the presence of Fe-MCM-48 reagent. Figure 6 shows that the optimized value for pH is 4. The mechanism of dechloronation of chlorophenols by ZVI is reported as follows [21, 22]:

Equations (1) and (4) show that the hydrogen ions are consumed in dechloronation of 2,4-DCP. Thus, it is expected that the dechloronation efficiency is increased in pH values of <7. On the other hand, the oxidation of zero-valent iron is more probable in acidic pH values. Therefore, the optimized pH value of 4 is a reasonable result. Also, the variation of sample pH is small during the reaction period so that the pH of 4 is varied to pH of 4.3 at the end of the reaction.

There are three steps in the dechlorination process of 2,4-DCP by ZVI nanoparticles in a solid–liquid two-phase reaction. The mass transfer of 2,4-DCP from solution to the metal surface, adsorption, and dechlorination of 2,4-DCP on the metal surface and desorption of the dechlorination products from the metal surface and diffuse into the bulk solution. The mass transfer control can be ruled out as governing the reaction rate in the first and third steps. The adsorption process of 2,4-DCP on surface of nanoparticles in the second step also proceeds easily. Therefore, dechlorination is likely the rate-determining step for the degradation of 2,4-DCP by metal nanoparticles [5, 6].

The chlorine group of the chlorophenols is highly electronegative and electron withdrawing group [21]. Because the negative potential of ZVI, it tends to lose electrons to become ferrous (Reaction 2). Hence, it is highly attracted towards the chlorine group of chlorophenols, leading to the dechlorination of chlorophenols (Reaction 4). The electron from ZVI is first transferred to the chlorine group nearer to the hydroxyl group leading to its liberation as chloride ion. This might be due to increase in electron deficiency in the proximity to chlorine group near the electron with drawing hydroxyl group. Hence, only chlorophenol and phenol have formed during dechlorination of DCP [21, 22].

The dechloronation efficiency is increased with increasing of dosage of Fe-MCM-48 from 50 to 150 mg/L and then leveled off at higher amounts (Fig. 7). The collusion between 2,4-DCP molecules and Fe-MCM-48 particles is enhanced in higher amounts of Fe-MCM-48 as a reactant. Also, as seen from Eqs. (1–6), in dechloronation reaction, the Fe0 particles are oxidized and Fe2+ and Fe3+ ions are produced with progress of the reaction. Thus, the loss of Fe0 particles in reagent of Fe-MCM-48 is expected according to the proposed mechanism. As a result, the higher amounts of ZVI nanoparticles in reagent increase the dechloronation efficiency.

The effect of initial concentration of 2,4-DCP on the dechlorination efficiency is studied at amplitude of 100–400 mg/L. Figure 8 shows the increasing of dechlorination efficiency up to 200 mg/L of 2,4-DCP and then a reduction is seen for concentration >200 mg/L. The increasing in the collusion between molecules of 2,4-DCP and Fe-MCM particles is expected with increasing of initial concentrations of pollutant. But, the yield of removal was decreased with increasing of initial concentration from 200 to 400 mg/L of 2,4-DCP. At higher concentrations of pollutant, the limitation in available sites of reagent for dechlorination process can be the reason for the decrease of dechlorination efficiency [23, 24].

Dechloronation kinetic

Kinetic rate constants of dechlorination reaction based on the decreasing of 2,4-DCP concentration is studied at pH = 4 and 150 mg/L of Fe-MCM-48. Also, for comparison of reactivity of Fe-MCM-48 reagent and ZVI particles, the kinetic of dechlorination reaction is studied in the presence of reagent of zero-valent iron particles (37.5 mg/L) at pH 4. The amount of ZVI is selected on the base of percentage of NZVI in impregnated MCM-48. The pseudo first-order kinetic equation (Eq. 7) is used to calculate the kinetic rate constant (k) of dechlorination reaction [25, 26]. The obtained results are given in Table 1.

In Eq. (7), Co and Ct are the initial concentration and concentration of 2,4-DCP at time t, respectively.

The obtained data of Table 1 are indicated the superior of proposed composition as a new reagent versus ZVI particles for dechloronation reaction of chlorophenol compounds. The kinetic rate constant of dechloronation reaction is increased 1.1–1.3 times in the presence of Fe-MCM-48 versus ZVI particles. This increasing of kinetic rate constant can be related to the increasing of available surface of Fe-MCM-48 reagent for collusion with 2,4-DCP molecules [27, 28]. The surface (S) of MCM-48, Fe-MCM-48 and ZVI nanoparticles are obtained 856.2, 543.4 and 34.5 m2/g by BET data, respectively. However, the reaction of adsorbed 2,4-DCP with ZVI nanoparticles may also become a determining factor since the ZVI nanoparticles are located in the inner part of the mesopore of MCM-48. But, the obtained kinetic rate constants and surface area data showed the superior of surface increasing of proposed reagent versus this limitation. On the other hand, the adsorption of 2,4-DCP molecules on the surface of mesoporous MCM-48 can be due to effective collusion of pollutant molecules with ZVI nanoparticles in pores of MCM-48 [29, 30]. Based on the proposed mechanism (Eqs. 1–6), the adsorbed molecules of 2,4-DCP are dechloronated upon reaction with NZVI impregnated MCM-48.

Reusability of Fe-MCM-48

The Fe-MCM-48 as a heterogeneous catalyst can be reusable in dechloronation process. The used reagent is removed, washed with ethanol, water and acetone, and dried at N2 atmosphere and temperature of 50 °C. The N2 gas is used to removal solvents in elution step. The minor adsorbed molecules of 2,4-DCP in reagent is separated by washing ethanol, water, and acetone.

However, there is a decrease in the dechlorination efficiency of 2,4-DCP. Dechlorination efficiency is obtained as 95.8, 71.3, 54.3, and 37.5 % in four-cycles of dechloronation reaction. The decrease of dechlorination in consecutive cycles might be due to leaching out of the iron from the reagent. Reimpregnation of Fe3+ ions onto MCM-48 is also tried by soaking it in saturated FeCl3 solution and NaBH4 solution, respectively. Dechloronation of 2,4-DCP is repeated for four cycles with reimpregnated MCM-48 after each usage of reagent. Dechlorination efficiency at the presence of reimpregnated MCM-48 is obtained as 94.3, 87.6, 72.6, and 59.2 % in four cycles.

Conclusions

The zero-valent iron impregnated in MCM-48 can be used for dechloronation of 2,4-dichlorophenol as a pollutant. The efficiency of dechloronation is increased in the presence of Fe-MCM-48 versus ZVI particles because the increasing of surface of reagent. The dechloronation reaction shows a first-order kinetic with rate constant of 0.425 h−1 at conditions of pH 4, 150 mg/L of Fe-MCM-48, and 200 mg/L of 2,4-DCP. A reproducible nearly behavior was obtained for the proposed reagent in each reimpregnated stage with dechloronation efficiency of 95–55 % for four cycles of reaction.

References

Zhang WX, Wang CB, Lien HL (1998) Treatment of chlorinated organic contaminants with nanoscale bimetallic particles. Catal Today 40:387–395

Pouretedal HR, Hasanali MA (2013) Photocatalytic degradation of some β-lactam antibiotics in aqueous suspension of ZnS nanoparticles. Desalin Water Treat 51:2617–2623

Choe S, Chang YY, Hwang KY (2000) Kinetics of reductive denitrification by nanoscale zero-valent iron. Chemosphere 41:1307–1311

Masciangioli T, Zhang WX (2003) Environmental technologies at the nanoscale. Environ Sci Technol 37:102A–108A

Zhang WX (2003) Nanoscale iron particles for environmental remediation: an overview. J Nanopart Res 5:323–332

Song H, Carraway W (2005) Reduction of chlorinated ethanes by nanosized zero-valent iron: kinetics, pathways and effects of reaction conditions. Environ Sci Technol 39:6237–6245

Alessi DS, Zhao HL (2001) Synergistic effect of cationic surfactants on perchloroethylene degradation by zero-valent iron. Environ Sci Technol 35:3713–3717

Lowry GV, Johnson KM (2004) Congener specific dechlorination of dissolved PCBs by microscale and nanoscale zero valent iron in a water/methanol solution. Environ Sci Technol 38:5208–5216

Jovanovic GN, Znidarsic PP, Sakrittichai P (2005) Dechlorination of p-chlorophenol in a microreactor with bimetallic Pd/Fe catalyst. Ind Eng Chem Res 44:5099–5106

Dombek T, Davis D, Stine J (2004) Degradation of terbutylazine (2-chloro-4-ethylamino-6-terbutylamino-1,3,5-triazine), deisopropyl atrazine(2-amino-4-chloro-6-ethylamino-1,3,5-triazine), and chlorinated dimethoxytriazine (2-chloro-4,6-dimethoxy-1,3,5-triazine) by zero valent iron and electrochemical reduction. Environ Poll 129:267–275

Keum YS, Li QX (2005) Reductive debromination of polybrominated diphenylethers by zero-valent iron. Environ Sci Technol 39:2282–2286

Park S, Baeck SH, Kim TJ, Chung YM, Oh SH, Song IK (2010) Direct synthesis of hydrogen peroxide from hydrogen and oxygen over palladium catalyst supported on SO3H-functionalized mesoporous silica. J Mol Catal A 319:98–107

Zanjanchi MA, Ebrahimian A, Arvand M (2010) Sulphonated cobalt phthalocyanine–MCM-41: an active photocatalyst for degradation of 2,4-dichlorophenol. J Hazard Mater 175:992–1000

Corma A (1997) Frommicroporous to mesoporous molecular sieve materials and their use in catalysis. Chem Rev 97:2373–2420

Yang H, Deng Y, Du C (2009) Synthesis and optical properties of mesoporous MCM-41 containing doped TiO2 nanoparticles. Colloids Surf A Physicochem Eng Asp 339:111–117

Le C, Xiaoqin L (2008) π-Complexation mesoporous adsorbents Cu-MCM-48 for ethylene-ethane separation. Chin J Chem Eng 16:570–574

Anpo M, Yamashita H, Ikeue K (1998) Photocatalytic reduction of CO2 with H2O on Ti-MCM-41 and Ti-MCM-48 mesoporous zeolite catalysts. Catal Today 44:327–332

Shao YF, Wang LZ, Zhang JL (2006) The photoluminescence of rhodamine B encapsulated in mesoporous Si-MCM-48, Ce-MCM-48 and Fe-MCM-48 and Cr-MCM-48 molecular sieves. J Photochem Photobiol A 180:59–64

Hadjiivanov K, Tsoncheva T, Dimitrov M, Minchev C, Knözinger H (2003) Characterization of Cu/MCM-41 and Cu/MCM-48 mesoporous catalysts by FTIR spectroscopy of adsorbed CO. Appl Catal A 241:331–340

Cheng R, Wang J-L, Zhang W-X (2007) Reductive dechlorination of p-chlorophenol by nanoscale iron. Biomed Environ Sci 20:410–413

Dorathi PJ, Kandasamy P (2012) Dechlorination of chlorophenols by zero valent iron impregnated silica. J Environ Sci 24:765–773

Deng B, Burniss DR, Campbell TJ (1999) Reductive vinyl chloride in metallic iron–water systems. Environ Sci Technol 33:2651–2656

Pouretedal HR, Ahmadi M (2012) Synthesis, characterization, and photocatalytic activity of MCM-41 and MCM-48 impregnated with CeO2 nanoparticles. Int Nano Lett 2:10. doi:10.1186/2228-5326-2-10

Pouretedal HR, Basati S (2012) Synthesis, characterization and photocatalytic activity of CeO2-SBA-15. Iran J Catal 2:50–54

Ghauch A (2001) Degradation of benomyl, picloram, and dicamba in a conical apparatus by zero valent iron. Chemosphere 43:1109–1117

Kim H, Hong HJ, Lee YJ, Shin HJ, Yang JW (2008) Degradation of trichloroethylene by zero-valent iron immobilized in cationic exchange membrane. Desalination 223:212–220

Huang L, Su G, Zhang A, Shi Y, Xia C, Lu H, Li L, Liu S, Zheng M (2013) Degradation of polychlorinated biphenyls using mesoporous iron-based spinels. J Hazard Mater 261:451–462

Cheng L, Jin Z, Wang X (2013) Hydrodechlorination of chlorophenols at low temperature over highly defective Pd catalyst. Catal Commun 41:60–64

Lee C, Doong R (2014) Enhanced dechlorination of tetrachloroethylene by polyethylene glycol-coated zerovalent silicon in the presence of nickel ions. Appl Catal B 144:182–188

Yoneda T, Aoyama T, Takido T, Konum K (2013) Hydrodechlorination of para chloroacetophenone with water-repellent platinum catalysts in a water/ethanol mixed solvent. Appl Catal B 142–143:344–353

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Pouretedal, H.R., Saedi, E. Dechlorination of 2,4-dichlorophenol by zero-valent iron nanoparticles impregnated MCM-48. Int J Ind Chem 5, 77–83 (2014). https://doi.org/10.1007/s40090-014-0021-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40090-014-0021-9