Abstract

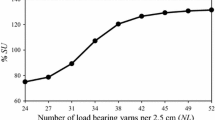

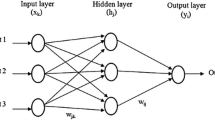

The main goal of using core yarn is to take benefit from the various qualities of its components. The filament used in core yarn adds strength to the yarn, while the sheath fibers gives the appearance and physical attributes. As the property of yarn is influenced by the core, the variation of core provides option for widening application of core spun yarn. In recent days, stretch denim fabrics have raised the potential application of denim fabric in apparel sector. The process parameters influence the structure and ultimately the behavior of the yarn and that of the product made out of it. Optimization of the parameters can help in economic production of the best quality of product using available resources. In our study process parameters such as linear density, stretch percentage of lycra and testing parameters such as gauge length and speed of testing are optimized to get high elastic recovery and tenacity of yarn. The error percentage for optimized results is not more than 7 percent so model is valid for actual usage.

Similar content being viewed by others

References

S. Kumar, K. Chatterjee, R. Padhye, R. Nayak, Designing and development of denim fabrics: Part 1-study the effect of fabric parameters on the fabric characteristics for women’s wear. J. Textile Sci. Eng. 6(4), 1–5 (2016)

H.I. Çelik, H.K. Kaynak, An investigation on the effect of elastane draw ratio on air permeability of denim bi-stretch denim fabrics. IOP Conference Series: Materials Science and Engineering, vol. 254, 8, pp. 082007 (2017)

N. Gokarneshan, K. Velumani, R. Sandipkumar, R. Malathi, Exploring the versatility of denim fabrics—a review of some significant insights on recent researches. Curr Trends Fash Technol Textile Eng 2(4), 62–68 (2018)

N. Özdil, Stretch and bagging properties of denim fabrics containing different rates of elastane. Fibres Text Eastern Eur 16(1), 66 (2008)

N. Varghese, G. Thilagavathi Handle and comfort characteristics of cotton core spun lycra and polyester/lycra fabrics for application as blouse. J. Text. Apparel. Technol. Manage. 8(4) (2014)

X. Zhang, Y. Li, K.W. Yeung, M. Yao, Fabric bagging: part I: subjective perception and psychophysical mechanism. Text. Res. J. 69(7), 511–518 (1999)

A. Das, R. Chakraborty, Studies on elastane-cotton core-spun stretch yarns and fabrics: Part I–Yarn characteristics. Indian J. Fibres Text. Res. 38, 340 (2013)

E. Sarioğlu, O. Babaarslan, A comparative strength analysis of denim fabrics made from core-spun yarns containing textured microfilaments. J. Eng. Fibers Fabr. 12(1), 155892501701200100 (2017)

M. Shanbeh, H. Hasani, F.Y. Manesh, An investigation into the fatigue behavior of core-spun yarns under cyclic tensile loading. J. Eng. Fibers Fabr. 7(4), 155892501200700400 (2012)

M. Dang, Z. Zhang, S. Wang, Properties of wool/spandex core-spun yarn produced on modified woolen spinning frame. Fibers Polym. 7, 420–423 (2006)

G.K. Tyagi, A. Goyal, A. Patnaik, Elastic recovery properties of polyester jet-spun yarns. Indian J. Fibre Text. Res. 27, 352 (2002)

C.I. Su, M.C. Maa, H.Y. Yang, Structure and performance of elastic core-spun yarn. Text. Res. J. 74(7), 607–610 (2004)

M. Ertekin, E. Kirtay, Tensile properties of some technical core spun yarns developed for protective textiles. Text. Apparel 25(2), 104–110 (2015)

S. Esin, B. Osman, Fatigue behaviour of core-spun yarns containing filament by means of cyclic dynamic loading, In IOP Conference Series: Materials Science and Engineering, vol. 254, no. 8, pp. 082012 (2017).

B.R. Das, Tensile behaviour of spun yarns under static state. J. Eng. Fibers Fabr. 5(1), 155892501000500100 (2010)

A. Majumdar, R. Sengupta, Effect of extension rate and specimen length on tenacity and breaking extension of polyester/viscose twin-spun air-jet yarns. Indian J. Fibres Text. Res. 28, 182 (2003)

N. Balasubramanian, V.K. Bhatnagar, the effect of spinning conditions on the tensile properties of core-spun yarns. J. Text. Inst. 61(11), 534–554 (1970)

M.M. Mourad, M.H. Elshakankery, A. Almetwally, Physical and stretch properties of woven cotton fabrics containing different rates of spandex. J. Am. Sci. 8(4), 567–572 (2012)

S.K. Sinha, P. Bansal, S. Maity, Tensile and elastic performance of cotton/lycra core spun denim yarn. J. Inst. Eng. Ser. E 98, 71–78 (2017)

P. Bansal, S. Maity, S.K. Sinha, Effects of process parameters on tensile and recovery behavior of ring-spun cotton/lycra denim yarn. J. Inst. Eng. Ser. E 100, 37–45 (2019)

C.W. Lou, C.W. Chang, J.H. Lin, C.H. Lei, W.H. Hsing, Production of a polyester core-spun yarn with spandex using a multi-section drawing frame and a ring spinning frame. Text. Res. J. 75(5), 395–401 (2005)

T. Chen, C. Zhang, X. Chen, L. Li, A soft computing model for predicting yarn tenacity. Res. J. Text. Appar. 11, 80–86 (2007)

R. Rajamanickam, S.M. Hansen, S. Jayaraman, Analysis of the modeling methodologies for predicting the strength of air-jet spun yarns. Text. Res. J. 67(1), 39–44 (1997)

A. Majumdar, P.K. Majumdar, B. Sarkar, Application of an adaptive neuro-fuzzy system for the prediction of cotton yarn strength from HVI fibre properties. J. Text. Inst. 96(1), 55–60 (2005)

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nurussaba, K., Sinha, A., Bhatia, D. et al. Modeling of Lycra/Cotton Core Spun Yarn for Strength and Elastic Recovery Using Adaptive Neuro-Fuzzy Inference System (ANFIS). J. Inst. Eng. India Ser. E (2024). https://doi.org/10.1007/s40034-024-00288-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40034-024-00288-w