Abstract

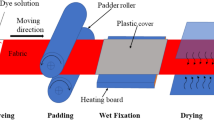

This research work investigates the dyeing process of 100% cotton yarn samples with indigo dye using the exhaust method. The study focuses on the effects of various dyeing factors, including dipping time, temperature, and oxidation time, using a Box–Behnken statistical design. Experimental results were analyzed through response surface curves to comprehensively assess the impact of these factors on color yield and color tone. These findings offer valuable insights into the exhaust dyeing process of indigo on cotton yarn, highlighting the crucial role of dipping time, temperature, and oxidation time in achieving desired dyeing outcomes. The study demonstrates that extending the dipping time and oxidation time resulted in higher K/S values, indicating enhanced dye adherence. However, the higher values of temperature negatively affects dye uptake. The research additionally contrasts the exhaust dyeing technique with continuous dyeing, wherein the yarn samples underwent dyeing in four and eight consecutive baths, respectively. The yarn samples dyed through exhaust dyeing exhibit a lighter shade with a tendency toward a more bluish tone when compared to yarn dyed using continuous dyeing. Nonetheless, the continuous dyeing method provides a layer-by-layer uniform dyeing effect, recognized as the ring dyeing effect. Additionally, cross-section analysis reveals that exhaust dyeing allows for higher penetration of indigo dye compared to continuous dyeing.

Similar content being viewed by others

References

J. Park, Rev. Prog Col. 34, 86–94 (2004)

S. Dutta, P. Bansal et al., Cotton fiber and yarn dyeing, in Cotton Science and Processing Technology Textile Science and Clothing Technology. ed. by H. Wang, H. Memon (Springer, Singapore, 2020), pp.355–375

A.D. Broadbent, Basic Principles of Textile Coloration (UK, West Yorkshire, 2001), pp.180–189

G.A. Baig, Color. Technol. 128(2), 114–120 (2012)

G.A. Baig, J. Text. Inst. 102(1), 87–92 (2011)

K. Hunger, Industrial Dyes—Chemistry Properties and Application Edited (Wiley, London, 2003), pp.340–349

S. Rai, R. Saremi, S. Sharma, S. Minko, Green Chem. 23(20), 7937–7944 (2021)

M. Abdelileh, M. Ben Ticha, N. Meksi, Fibers Polym. 22(7), 1863–1873 (2021)

M.B. Ticha, N. Meksi, N. Drira, M. Kechida, M.F. Mhenni, Ind. Crops Prod. 46, 350–358 (2013)

J.N. Chakraborty, R.B. Chavan, Ind. J. Fibre Text. Res. 39, 100–109 (2004)

J.H. Xin, C.L. Chong, T. Tu, Color. Technol. 116(9), 260–265 (2000)

S. Dhamija, R.K. Varshney, Ind. J. Fibre Text. Res. 43, 330–335 (2018)

B.J. Winer, D.R. Brown, K.M. Michels, Statistical Principles in Experimental Design (McGraw-Hill, New York, 1971)

S.R. Maulik, P. Pandit, Advancement in indigo dyeing. Text Dyes Pigments Green Chem. Approach. 19, 107–121 (2022)

J.N. Etters, Text. Chem. Color. 27(2), 17 (1995)

A.A. Christy, O.M. Kvalhei, R.A. Velapoldi, Vib. Spectrosc. 9(1), 19 (1995)

R.G. Kuehni, Color Space and Its Divisions Color Order from Antiquity to the Present (Wiley, Hoboken, 2003), p.92

K. Witt CIE Color Difference Metrics in Colorimetry Understanding the CIE In: System Ja ´NosSchanda, Wiley, 2007, p. 84.

M.G. Uddin, Chem. Mater. Eng. 2(7), 149–154 (2014)

N. Meksi, M.B. Ticha, M. Kechida, M.F. Mhenni, J. Clean. Prod. 24, 149–158 (2012)

P. A. Annis, J. N. Etters, & G. L. Baughman, Can. Text. J., 20–23 (1991).

R. Paul, Indigo Dyeing Technology for Denim Yarns, Denim: Manufacture, Finishing and Applications (Elsevier, UK, 2015), pp.74–100

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The research work was carried out without any external funding and authors have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meena, J., Saraswat, H. Optimizing Dyeing Parameters for Indigo on Cotton Yarn: A Comparative Study of Exhaust Dyeing and Continuous Dyeing Techniques. J. Inst. Eng. India Ser. E (2024). https://doi.org/10.1007/s40034-024-00285-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40034-024-00285-z