Abstract

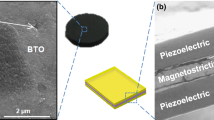

Simulations of mechanical or comfort properties of fibers, yarns and textile fabrics have been developed for a long time. In the course of increasing interest in smart textiles, models for conductive fabrics have also been developed. The magnetic properties of fibers or magnetic coatings, however, are almost exclusively being examined experimentally. This article thus describes different possibilities of micromagnetically modeling magnetic fibers or coatings. It gives an overview of calculation times for different dimensions of magnetic materials, indicating the limits due to available computer performance and shows the influence of these dimensions on the simulated magnetic properties for magnetic coatings on fibers and fabrics.

Similar content being viewed by others

References

A. Tabiei, I. Ivanov, Computational micro-mechanical model of flexible woven fabric for finite element impact simulation. Int. J. Numer. Method Eng. 53, 1259–1276 (2001)

T.J. Kan, W.R. Yu, Drape simulation of woven fabric by using the finite-element method. J. Text. Inst. 86, 635–648 (1995)

T. Ishikawa, T.W. Chou, Stiffness and strength behaviour of woven fabric composites. J. Mater. Sci. 17, 3211–3220 (1982)

M. de Araújo, R. Fangueiro, H. Hong, Modelling and simulation of the mechanical behavior of weft-knitted fabrics for technical applications—Part 2: 3D model based on the elastica theory. AUTEX Res. J. 3, 166–172 (2004)

N. Takano, Y. Ohnishi, M. Zako, K. Nishiyabu, Microstructure-based deep-drawing simulation of knitted fabric reinforced thermoplastics by homogenization theory. Int. J. Solids Struct. 38, 6333–6356 (2001)

M. Duhovic, D. Bhattacharyya, Simulating the deformation mechanisms of knitted fabric composites. Compos. A Appl. Sci. Manuf. 37, 1897–1915 (2006)

Y. Li, Z. Luo, An improved mathematical simulation of the coupled diffusion of moisture and heat in wool fabric. Text. Res. J. 69, 760–768 (1999)

J. Fan, Z. Luo, Y. Li, Heat and moisture transfer with sorption and condensation in porous clothing assemblies and numerical simulation. Int. J. Heat Mass Transf. 43, 2989–3000 (2000)

Y. Du, J. Li, Dynamic moisture absorption behavior of polyester-cotton fabric and mathematical model. Text. Res. J. 80, 1793–1802 (2010)

X. Zhang, Y. Li, K.W. Yeung, M. Yao, Mathematical simulation of fabric bagging. Text. Res. J. 70, 18–28 (2000)

S. Aumann, S. Trummer, A. Brücken, A. Ehrmann, A. Büsgen, Conceptual design of a sensory shirt for fire-fighters. Text. Res. J. 84, 1661–1665 (2014)

J. Wang, H. Long, S. Soltanian, P. Servati, F. Ko, Electromechanical properties of knitted wearable sensors: part I—theory. Text. Res. J. 84, 3–15 (2014)

J. Wang, H. Long, S. Soltanian, P. Servati, F. Ko, Electro-mechanical properties of knitted wearable sensors: part 2—parametric study and experimental verification. Text. Res. J. 84, 200–213 (2014)

H. Zhang, X. Tao, S. Wang, T. Yu, Electro-mechanical properties of knitted fabric made from conductive multi-filament yarn under unidirectional extension. Text. Res. J. 75, 598–606 (2005)

H. Zhang, X. Tao, S. Wang, Modeling of electro-mechanical properties of conductive knitted fabrics under large uniaxial deformation. Qual. Text. Qual. Life 1–4, 1109–1112 (2004)

Y. Kun, S. Guang-li, Z. Liang, L. Li-wen (2009) Modelling the electrical property of 1 × 1 rib knitted fabrics made from conductive yarns, in Proceedings of the ICIC 2009: Second International Conference on Information and Computing Science, vol. 4, pp. 382–385

A. Amarjargal, L.D. Tijing, C.H. P, I.T. Im, C.S. Kim, Controlled assembly of super paramagnetic iron oxide nanoparticles on electrospun PU nanofibrous membrane: a novel heat-generating substrate for magnetic hyperthermia application. Eur. Polym. J. 49, 3796–3805 (2013)

M. Rubacha, J. Zieba, Magnetic textile elements. Fibres Text. East. Eur. 14, 49–53 (2006)

P. Ciureanu, G. Rudkowska, P. Rudkowski, J.O. Ström-Olsen, Magnetoresistive sensors with rapidly solidified permalloy fibers. IEEE Trans. Magn. 29, 2251–2257 (1993)

M. Rubacha, J. Zieba, Magnetic cellulose fibres and their application in textronics. Fibres Text. East. Eur. 15, 101–104 (2007)

S. Wiak, A. Firych-Nowacka, K. Smólka, Computer models of 3D magnetic microfibres used in textile actuators. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 29, 1159–1171 (2010)

J. Zieba, M. Frydrysiak, Modeling of textile magnetic core. Smartex Res. J. 1, 102–110 (2012)

M. Grecka, A. Rizvi, A. Ehrmann, J. Blums (2013) Influence of abrasion and soaking on reflective properties of Cu and Al coated textiles. in Proceedings of Aachen-Dresden International Textile Conference, Aachen/Germany, 28–29.11.2014

M. J. Donahue, D. G. Porter (1999) OOMMF User’s Guide, Version 1.0. Interagency Report NISTIR 6376, National Institute of Standards and Technology, Gaithersburg, MD

W. Scholz, J. Fidler, T. Schrefl, D. Suess, R. Dittrich, H. Forster, V. Tsiantos, Scalable parallel micromagnetic solvers for magnetic nanostructures. Comput. Mater. Sci. 28, 366–383 (2003)

N.A.M. Barakat, B. Kim, H.Y. Kim, Production of smooth and pure nickel metal nanofibers by the electrospinning technique: nanofibers possess splendid magnetic properties. J. Phys. Chem. C 113, 531–536 (2009)

T. Blachowicz, A. Ehrmann, Fourfold nanosystems for quaternary storage devices. J. Appl. Phys. 110, 073911 (2011)

Ehrmann A (2014) Examination and simulation of new magnetic materials for the possible application in memory cells. Dissertation thesis, Silesian University of Technology, Gliwice/Poland

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ehrmann, A., Blachowicz, T. Micromagnetic Simulation of Fibers and Coatings on Textiles. J. Inst. Eng. India Ser. E 96, 145–150 (2015). https://doi.org/10.1007/s40034-014-0054-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-014-0054-9