Abstract

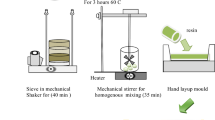

They are becoming a trend for natural fiber-made polymer composites, widespread in households, aero, automobiles, construction, etc. But the drawback is moisture absorption. Alkali chemical solution with 10% concentration is used to treat the coir natural fiber and adopted by 0, 5, 10, and 15 volume percentages to the epoxy matrix for synthesizing the composites using compression technique with an applied pressure of 100 MPa. The moisture absorption percentage, flexural strength, and fracture toughness of epoxy matrix and coir-reinforced epoxy composite are evaluated. Their results are compared to identify the best optimum composites for low-specific-weight applications. The 15 vol% of coir natural fiber (alkali treat) blended with epoxy provided a 12 ± 0.3% reduced water absorption percentage, 62 ± 2 MPa of improved flexural behavior, and a better feature toughness value of 1.49 ± 0.01 MPa m0.5.

Similar content being viewed by others

Data Availability

All the data required are available within the manuscript.

References

R. Sasikumar et al., Effect of tamarind fruit fiber contribution in epoxy resin composites as biodegradable nature: characterization and property evaluation. Biomass Conver. Biorefinery (2023)

K. Aruchamy et al., Influence of weave arrangements on mechanical characteristics of cotton and bamboo woven fabric reinforced composite laminates. J. Reinf. Plast. Compos. 42(11), 15 (2021)

I. Elfaleh et al., A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 19, 101271 (2023)

R. Venkatesh et al., Investigation and performance study of hibiscus sabdariffa bast fiber-reinforced HDPE composite enhanced by silica nanoparticles derived from agricultural residues. Fibers Polymers 1–10 (2023)

D.K. Pokkalla et al., A novel additive manufacturing compression over moulding process for hybrid metal polymer composite structures. Add. Manuf. Lett. 5, 100128 (2023)

S. Kumar et al., Physical and mechanical properties of natural leaf fiber-reinforced epoxy polyester composites. Polymers 13(9), 1396 (2021)

A. Balaji et al., Study on mechanical, thermal and morphological properties of banana fiber-reinforced epoxy composites. J. Bio- Tribo Corrosion 6, 60 (2020)

T.B. Yallew et al., Study on effect of process parameters on tensile properties of compression molded natural fiber reinforced polymer composites. SN Appl. Sci. 2, 338 (2020)

T.G.Y. Gowda et al., Areca/synthetic fibers reinforced based epoxy hybrid composites for semi-structural applications. Polym. Compos. 43(8), 5222–5234 (2022)

H.B. Rachid et al., Effect of nanocomposite rate on the crack propagation in the adhesive of single lap joint subjected to tension. Mech. Adv. Mater. Struct. (2023)

M. Krishnaraj et al., Fabrication and wear characteristics basalt fiber reinforced polypropylene matrix composites. SAE Technical paper, 2019–11–21

V. Ramesh et al., Influence of stacking sequence on mechanical properties of basalt/ramie biodegradable hybrid polymer composites. Polymers 15(4), 985 (2023)

F. Jahan, M. Soni, Effects of chemical treatment on mechanical properties of various natural fiber reinforced composite: a review. Mater. Today Proc. 46(15), 6708–6711 (2021)

I.S. Aji et al., Study of hybridized kenaf/palf-reinforced HDPE composites by dynamic mechanical analysis. Polym.-Plast. Technol. Eng.Plast. Technol. Eng. 51(2), 146–153 (2012)

A. Singh et al., Static, dynamic mechanical, and thermal analysis of coir/epoxy composites: Effect of hollow glass microspheres reinforcement. Polym. Compos. 44(12), 8529–8540 (2023)

W. Christraj, Performance analysis of solar water heater in multipurpose solar heating system. Appl. Mech. Mater. 592–594, 1706–1713 (2014)

P. Raja Sekaran, Adsorption and photocatalytic degradation properties of bimetallic Ag/MgO/biochar nanocomposites. Adsorp. Sci. Technol. 2022, Article ID 3631584 (2022). https://doi.org/10.1155/2022/3631584

N. Karthi, Synthesis and adsorbent performance of modified biochar with Ag/MgO nanocomposites for heat storage application. Adsorp. Sci. Technol. 2022, Article ID 7423102 (2022). https://doi.org/10.1155/2022/7423102

P.R. Sekaran, H. Ramakrishnan et al., Mechanical and physical characterization studies of nano ceramic reinforced Al–Mg hybrid nanocomposites. SILICON (2023). https://doi.org/10.1007/s12633-023-02473-9

W. Christraj, Experimental Investigation of Multipurpose Solar Heating System. J. Energy Eng. (2013). https://doi.org/10.1061/(ASCE)EY.1943-7897

Funding

The authors did not receive support from any organization for the submitted work. No funding was received to assist with the preparation of this manuscript. No funding was received for conducting this study. No funds, grants, or other support were received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose. The authors have no competing interests to declare relevant to this article's content. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

Ethics Approval

This is an observational study. Alkali process coir natural fiber incorporated epoxy composite made by compression mold route: Characteristics evaluation: The Research Ethics Committee has confirmed that no ethical approval is required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Venkatesh, R. Alkali Process Coir Natural Fiber Incorporated Epoxy Composite Made by Compression Mold Route: Characteristics Evaluation. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00723-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00723-7