Abstract

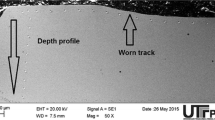

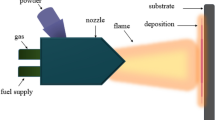

During friction surfacing of dissimilar alloys, different shielding techniques are used to avoid oxidation and corrosion behaviour of developed coatings. The present study explores the effect mechanical and corrosion performance of friction surfaced aluminium deposits over carbon steel by forced convection nitrogen shielding (FCNS) process. Appropriate friction surfacing process parameters are selected for experimental work, and the substrate plate was maintained a constant preheating temperature of 200 °C for obtaining better deposition. During deposition process, three different volume flow rates of nitrogen gas were supplied, namely FCNS-5, FCNS-10, and FCNS-15. The developed coating’s mechanical strength and corrosion behaviour are intensively investigated and compared with the coating developed by without apply of forced convention process (FCNS-0). The microstructural image received from electron backscattered diffraction (EBSD shows that the restoration activities and dynamically recrystallized grain growth are high towards higher volume of nitrogen supplied during FCNS process; as a result, an improved mechanical strength of the coating was achieved. Furthermore, the corrosion behaviour was analysed by electrochemical impedance and potentiodynamic polarization test. The impedance test shows a less corrosion current of the aluminium coating at FCNS-15 process. The potential dynamic polarization test confirms a lesser \(I_{{{\text{corr}}}}\) and higher \( E_{{{\text{corr}}}}\) value of aluminium coating in FCNS-15 process which proved a better corrosion resistance deposition compared to other processes.

Similar content being viewed by others

References

R. Chen, Q. Xu, H. Guo, Z. Xia, Q. Wu, B. Liu, Modeling the precipitation kinetics and tensile properties in Al-7Si-Mg cast aluminum alloys. Mater. Sci. Eng. 698, 249–255 (2017). https://doi.org/10.1016/j.msea.2017.05.055

N.D. Alexopoulos, Z. Velonaki, C.I. Stergiou, S.K. Kourkoulis, Effect of ageing on precipitation kinetics tensile and work hardening behavior of Al-Cu-Mg (2024) alloy. Mater. Sci. Eng. 700, 457–467 (2017). https://doi.org/10.1016/j.msea.2017.05.090

V. Sharma, U. Prakash, B.V.M. Kumar, Surface composites by friction stir processing: a review. J. Mater. Process. Technol. 224, 117–134 (2015). https://doi.org/10.1016/j.jmatprotec.2015.04.019

K. Martinsen, S.J. Hu, B.E. Carlson, Joining of dissimilar materials. CIRP Ann. Manuf. Technol 64, 679–699 (2015). https://doi.org/10.1016/j.cirp.2015.05.006

B. Vijaya Kumar, G. Madhusudhan Reddy, T. Mohandas, Influence of process parameters on physical dimensions of AA6063 aluminium alloy coating on mild steel in friction surfacing. Def. Technol. 11, 275–281 (2015). https://doi.org/10.1016/j.dt.2015.04.001

M.J.R. Stegmueller, P. Schindele, R.J. Grant, J. Mater, Inductive heating effects on friction surfacing of stainless steel onto an aluminium substrate. Process. Technol. 216, 430–439 (2015). https://doi.org/10.1016/j.jmatprotec.2014.10.013

U. Ashok Kumar, P. Laxminarayana, Friction surfacing process of aluminum alloys. In 5th international & 26th all India manufacturing technology, design and research conference (AIMTDR 2014) December,https://www.researchgate.net/publication/331861153_FRICTI

K. Prasad Rao, A. Veera Sreenu, Tool steel and copper coatings by friction surfacing – A thermography study. J Mater Process Technol 212, 402–407 (2012). https://doi.org/10.1016/j.jmatprotec.2011.09.023

W. Wang, G. Wang, Y. Hu, G. Guo, T. Zhou, Y. Rong, Temperature-dependent constitutive behavior with consideration of microstructure evolution for as-quenched Al-Cu-Mn alloy. Mater. Sci. Eng. 678, 85–92 (2016). https://doi.org/10.1016/j.msea.2016.09.090

E. Seidi, S.F. Miller, Lateral friction surfacing: experimental and metallurgical analysis of different aluminum alloy depositions. J. Market. Res. 15, 5948–5967 (2021). https://doi.org/10.1016/j.jmrt.2021.11.049

X.H. Zeng, P. Xue, L.H. Wu, D.R. Ni, B.L. Xiao, K.S. Wang, Z. Ma, Microstructural evolution of aluminum alloy during friction stir welding under different tool rotation rates and cooling conditions. J. Mater. Sci. Technol. 35(6), 972–981 (2019). https://doi.org/10.1016/j.jmst.2018.12.024

H. Lin, Y. Wu, S. Liu, X. Zhou, Effect of cooling conditions on microstructure and mechanical properties of friction stir welded 7055 aluminium alloy joints. Mater. Charact. 141, 74–85 (2018). https://doi.org/10.1016/j.matchar.2018.04.029

R.K.R. Singh, R. Prasad, S. Pandey, S.K. Sharma, Effect of cooling environment and welding speed on fatigue properties of friction stir welded Al-Mg-Cr alloy. Int. J. Fatigue. 127, 551–563 (2019). https://doi.org/10.1016/j.ijfatigue.2019.06.043

J.H. Cho, S.H. Han, C.G. Lee, Cooling effect on microstructure and mechanical properties during friction stir welding of Al-Mg-Si aluminum alloys. Mater. Lett. 180, 157–161 (2016). https://doi.org/10.1016/j.matlet.2016.05.157

S. Mohammed, M. Srivastava, R. Tripathi, S. Chattopadhyaya, A.R. Dixit, Feasibility study of friction surfaced coatings over non-ferrous substrates. Proc. Eng. 149, 465–471 (2016). https://doi.org/10.1016/J.PROENG.2016.06.693

V. Fitseva, S. Hanke, J.F. Dos Santos, Influence of rotational speed on process characteristics in friction surfacing of Ti-6Al-4V. Mater. Manuf. Process. 32(5), 557–563 (2017). https://doi.org/10.1080/10426914.2016.1257799

S. Ravisekhar, V. Chittaranjan Das, D., Govardhan, friction surfaced deposits for industrial applications. Mater. Today: Proc. 4(2), 3796–3801 (2017). https://doi.org/10.1016/J.MATPR.2017.02.276

K. Badheka, V. Badheka, Friction surfacing of aluminium on steel: an experimental approach. Mater. Today: Proc. 4(9), 9937–9941 (2017). https://doi.org/10.1016/j.matpr.2017.06.297

R. Kumar, S. Chattopadhyaya, A. Ghosh, G.M. Krolczyk, P. Vilaca, R. Kumar, M. Srivastava, M. Shariq, R. Triphathi, Characterization of friction surfaced coatings of AISI 316 tool over high-speed-steel substrate. Trans. FAMENA 41(2), 61–76 (2017). https://doi.org/10.21278/TOF.41206

S. Hanke, I. Sena, R.S. Coelho, J.F. dos Santos, Microstructural features of dynamic recrystallization in alloy 625 friction surfacing coatings. Mater. Manuf. Process. 33(3), 270–276 (2018). https://doi.org/10.1080/10426914.2017.1291947

VS Senthil Kumar, R Lokesh, C Rathinasuriyan, R Shankar (2015) Multi response optimization of submerged friction stir welding process parameters using TOPSIS approach, IMECE, 50353

S. Ramaiyan, R. Chandran, S. Santhanam, Effect of cooling conditions on mechanical and microstructural behaviours of friction stir processed AZ31B Mg alloy. Modern Mechanic Eng 7, 144–160 (2017). https://doi.org/10.4236/mme.2017.74010

V. Patel, W. Li, A. Vairis, V. Badheka, Recent development in friction stir processing as a solid-state grain refinement technique: microstructural evolution and property enhancement crit. Rev. Solid State Mater. Sci. 44, 378–426 (2019). https://doi.org/10.1080/10408436.2018.1490251

V.V. Patel, V. Badheka, A. Kumar, Friction stir processing as a novel technique to achieve superplasticity in aluminum alloys: process variables, variants, and applications Metallogr. Microstruct. Anal. 5, 278–293 (2016). https://doi.org/10.1007/s13632-016-0285-x

M.M. Moradi, H. Jamshidi Aval, R. Jamaati, Effect of pre and post welding heat treatment in SiC-fortified dissimilar AA6061-AA2024 FSW butt joint. J. Manuf. Process. 30, 97–105 (2017). https://doi.org/10.1016/j.jmapro.2017.08.014

R. Kosturek, L. Śnieżek, M. Wachowski, J. Torzewski, The influence of post-weld heat treatment on the microstructure and fatigue properties of Sc-modified AA2519 friction stir-welded joint. Materials. 12(4), 583 (2019). https://doi.org/10.3390/ma12040583

B. Safarbali, M. Shamanian, A. Eslami, Effect of post-weld heat treatment on joint properties of dissimilar friction stir welded 2024–T4 and 7075–T6 aluminum alloys. Transact Nonferrous Metals Soc China 28(7), 1287–1297 (2018). https://doi.org/10.1016/S1003-6326(18)64766-1

M.A. Wahid, A.N. Siddiquee, Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties. Transact Nonferrous Metals Soc China 28(2), 193–219 (2018). https://doi.org/10.1016/S1003-6326(18)64653-9

Y. Chen, Y. Jiang, H. Ding, J. Zhao, J. Li, Effects of friction-stir processing with water cooling on the properties of an Al–Zn–Mg–Cu alloy Mater. Sci. Technol. (United Kingdom) 34, 153–602 (2017). https://doi.org/10.1080/02670836.2017.1366709

V. Patel, V. Badheka, W. Li, S. Akkireddy, Hybrid friction stir processing with active cooling approach to enhance superplastic behavior of AA7075 aluminum alloy Arch. Civ. Mech. Eng. 19(4), 1368–1380 (2019). https://doi.org/10.1016/j.acme.2019.08.007

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahoo, D.K., Chaudhary, S.B., Neupane, N. et al. Improving the Mechanical and Corrosion Behaviour of Friction Surfaced Aluminium Deposition by Forced Convection Nitrogen Shielding Technique. J. Inst. Eng. India Ser. D 105, 503–516 (2024). https://doi.org/10.1007/s40033-023-00496-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-023-00496-5