Abstract

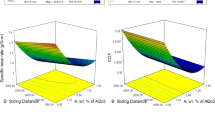

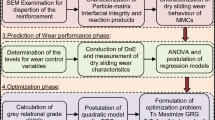

In this study, modelling of specific wear rate and worn surface roughness of Al-WC nanocomposites is attempted. For fabrication of Al-WC nanocomposites, the liquid metallurgy-based ex situ method is exercised. A tailored casting unit with ultrasonic vibration and mechanical stirrer setup is used for fabrication. As particulates are of nanosize, the maximum amount of reinforcement is restricted at 2wt.%. Tribological tests are executed on a pin-on-disc type tribotester. Surface roughness (Ra) of the tested surfaces is measured using a dedicated surface roughness tester. A design of experiment using the central composite design method has been prepared considering input parameters as wt.% of reinforcements (1%, 1.5%, and 2%), the load applied on tribological tests (10, 20, and 30N), and sliding speed (0.1, 0.2, and 0.3 m/s). Specific wear rate and Ra values of worn out surfaces are considered as output responses of this study. A second-order regression model is developed using experimental design method. The response surface method (RSM) is employed for this purpose. ANOVA is performed on the experimental results. Wt.% of reinforcement becomes the most significant parameter for specific wear rate. In the case of the Ra value, load (B) is the most significant parameter with a 58.63% level of significance. After performing a fresh set of experiments and fitting the results into the developed model, it is observed that the difference between actual results and predicted results is within a permissible range. Modelling has been attempted in this work to conclude wear performance of newly developed stir-cast Al-WC nanocomposites with minimum number of experiment. SEM micrographs and EDAX spectrum of wear debris collected from the worn surface are also attempted in the end. Formation of a mixed layer is confirmed which helps to develop better wear performance in composites with more WC as reinforcement. No sign of major ploughing or groove formation is observed.

Similar content being viewed by others

References

D. Roy, S. Ghosh, A. Basumallick, Mater. Sci. Eng. A 415(1–2), 202–206 (2006). https://doi.org/10.1016/j.msea.2005.09.100

S.P. Rawal, JOM 53, 14–17 (2001). https://doi.org/10.1007/s11837-001-0139-z

W. Gaohui, Z. Qiang, C. Guoqin, J. Longtao, X. Ziyang, J. Mater. Sci. Mater. Electron. 14, 9–12 (2003). https://doi.org/10.1023/A:1021567329773

A. Mussatto, I.U. Ahad, R.T. Mousavian, Y. Delaure, D. Brabazon, Eng. Rep. 3(5), e12330 (2021). https://doi.org/10.1002/eng2.12330

D. Gultekin, M. Uysal, S. Aslan, M. Alaf, M.O. Guler, H. Akbulut, Wear 270(1–2), 73–82 (2010). https://doi.org/10.1016/j.wear.2010.09.001

A. Pakdel, A. Witecka, G. Rydzek, S.D.N. Awang, Mater. Des. 119, 225–234 (2017). https://doi.org/10.1016/j.matdes.2017.01.064

M.K. Surappa, Sadhana 28, 319–334 (2003). https://doi.org/10.1007/BF02717141

S.V. Prasad, R. Asthana, Tribol. Lett. 17, 445–453 (2004). https://doi.org/10.1023/B:TRIL.0000044492.91991.f3

N. Hosseini, F. Karimzadeh, M.H. Abbasi, M.H. Enayati, Mater. Des. 31(10), 4777–4785 (2010). https://doi.org/10.1016/j.matdes.2010.05.001

X. Ma, Y.F. Zhao, W.J. Tian, Z. Qian, H.W. Chen, Y.Y. Wu, X.F. Liu, Sci. Rep. 6, 34919 (2016). https://doi.org/10.1038/srep34919

K.S.R. Raju, P.R.M. Raju, S. Rajesh, V.R. Raju, P. Ghosal, J. Compos. Mater. 50(26), 3627–3641 (2016). https://doi.org/10.1177/0021998315623624

M.O. Shabani, A.A. Tofigh, F. Heydari, A. Mazahery, Prot. Met. Phys. Chem. Surf. 52, 244–248 (2016). https://doi.org/10.1134/S2070205116020192

Z. Zhang, J. Liu, T. Wu, Y. Xie, Friction 5, 147–154 (2017). https://doi.org/10.1007/s40544-016-0126-6

N.K. Bhoi, H. Singh, S. Pratap, J. Compos. Mater. 54(6), 813–833 (2020). https://doi.org/10.1177/0021998319865307

I.J. Shon, Ceram. Int. 42(15), 17884–17891 (2016). https://doi.org/10.1016/j.ceramint.2016.07.050

A. Pal, S. Poria, G. Sutradhar, P. Sahoo, Mater. Res. Express. 5(3), 036521 (2018). https://doi.org/10.1088/2053-1591/aab577

A. Lekatou, A.E. Karantzalis, A. Evangelou, V. Gousia, G. Kaptay, Z. Gácsi, P. Baumli, A. Simon, Mater. Des. 65, 1121–1135 (2015). https://doi.org/10.1016/j.matdes.2014.08.040

Y. Yang, J. Lan, X. Li, Mater. Sci. Eng. A 380(1–2), 378–383 (2004). https://doi.org/10.1016/j.msea.2004.03.073

H. Puga, J. Barbosa, S. Costa, S. Ribeiro, A.M.P. Pinto, M. Prokic, Mater. Sci. Eng. A 560, 589–595 (2013). https://doi.org/10.1016/j.msea.2012.09.106

Y. Yang, X. Li, J. Manuf. Sci. Eng. 129(2), 252–255 (2007). https://doi.org/10.1115/1.2194064

N. Selvakumar, B. Gnanasundarajayaraja, P. Rajeshkumar, Exp. Tech. 40, 129–135 (2016). https://doi.org/10.1007/s40799-016-0015-y

K. Ravikumar, K. Kiran, V.S. Sreebalaji, Measurement 102, 142–149 (2017). https://doi.org/10.1016/j.measurement.2017.01.045

S. Arivukkarasan, V. Dhanalakshmi, B. Stalin, M. Ravichandran, Part. Sci. Technol. 36(8), 967–973 (2018). https://doi.org/10.1080/02726351.2017.1331285

S. Veličković, B. Stojanović, M. Babić, I. Bobić, J. Compos. Mater. 51(17), 2505–2515 (2017). https://doi.org/10.1177/0021998316672294

N. Bharat, P.S.C. Bose, Silicon 12, 1–17 (2023). https://doi.org/10.1007/s12633-023-02423-5

A.A. Adediran, A.A. Akinwande, O.A. Balogun, B.J. Olorunfemi, M.S. Kumar, Sci. Rep. 11, 19860 (2021). https://doi.org/10.1038/s41598-021-99168-1

A.I. Khuri, J.A. Cornell, Response surfaces: designs and analyses (CRC Press Routledge, Taylor & Francis Group, 2018)

S. Sardar, S.K. Karmakar, D. Das, Measurement 127, 42–62 (2018). https://doi.org/10.1016/j.measurement.2018.05.090

Y. Sahin, K. Özdin, Mater. Des. 29(3), 728–733 (2008). https://doi.org/10.1016/j.matdes.2007.02.013

S. Sardar, S.K. Pradhan, S.K. Karmakar, D. Das, J. Tribol. 141, 7 (2019). https://doi.org/10.1115/1.4043642

E.A. Diler, R. Ipek, Compos. B. Eng. 50, 371–380 (2013). https://doi.org/10.1016/j.compositesb.2013.02.001

A. Kumar, M.M. Mahapatra, P.K. Jha, Wear 306(1–2), 170–178 (2013). https://doi.org/10.1016/j.wear.2013.08.013

Funding

Nil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

Nil.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Das, R.K., Poria, S. & Sahoo, P. Modelling of Dry Sliding Wear Performance of Al-WC Nanocomposites. J. Inst. Eng. India Ser. D 105, 461–475 (2024). https://doi.org/10.1007/s40033-023-00494-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-023-00494-7