Abstract

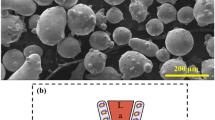

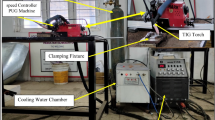

In the present study, an attempt was made to develop surface cladding on stainless steel-304 steel by utilizing a mixture of 80% nickel and 20% chromium carbide powder via microwave energy. The microwave cladding process on the stainless steel-304 was carried out in the in-house developed set-up on the microwave. The microwave cladding process was carried out on 900 W with a 2.45 GHz frequency for 120 s. The microstructure image of the developed surface showed the presence of chromium carbide particles. EDX pattern of stainless steel-304 coating with 80% nickel and 20% chromium carbide showed the presence of elements such as Ni, Fe, C, Cr, Si, and O with wt% of 59.58%, 23.86%, 7.92%, 5.88%, 1.87% and 0.89%, respectively. Homogeneity of the cladding layer and cladding surface has been identified by observing the thickness of the cladding layer and cladding surface, respectively. A uniform cladding layer with fewer dark pixels has been observed with higher homogeneity. X-ray diffraction of the cladding surface shows the presence of iron, iron–nickel (1/3), chromium silicide, nickel silicide, heptachromium tricarbide, hexagonal nickel carbide, nickel carbide, and chromium-nickel (3/2) phases. The hardness of stainless steel-304 was improved by about 47.61%. The main reason for the increase in hardness is the formation of different carbides such as chromium silicide, heptachromium tricarbide, hexagonal nickel carbide, nickel carbide, and chromium-nickel (3/2) phases. The wear rate and coefficient of friction of the developed cladding surface with 80% nickel and 20% chromium carbide were found to be 0.00143 mm3/m and 0.2412, respectively. However, few dark spots were observed in the corroded surface of the cladding layer which indicated some corrosion in 3.5 wt% sodium chloride environment.

Similar content being viewed by others

References

A.K. Sharma, S. Aravindhan, R. Krishnamurthy, Mater. Lett. 50, 295–301 (2011)

S. Zhou, X. Zeng, H. Qianwu, S. Huang, Appl. Surf. Sci. 255, 1646–1653 (2008)

R.C. Leonelli, P. Veronesi, L. Denti, A. Gatto, L. Iuliano, J. Mater. Process. Technol. 205, 489–496 (2008)

J. Mateos, J.M. Cuetos, E. Fernandez, R. Vijande, Wear 239, 274–281 (2000)

D.R. Agrawal, J. Cheng, S. Gedevanishvili, Nature 339, 668–670 (1999)

A. Mondal, A. Upadhyaya, D. Agrawal, J. Microw. Power Electromagn. Energy 44, 28–44 (2009)

P. Chhillar, D. Agrawal, J.H. Adair, Powder Metall. 51, 182–187 (2008)

A. Zambon, E. Ramous, Laser Eng. 2, 163–167 (1993)

D. Gupta, A.K. Sharma, P.M. Bhovi, S. Dutta, J. Manuf. Processes 14, 243–249 (2012)

R.I. Badigera, S. Narendranath, M.S. Srinath, J. Manuf. Processes 18, 117–123 (2015)

M.A. Janney, C.L. Calhoun, H.D. Kimrey, J. Am. Ceram. Soc. 75, 341–346 (1992)

O.L. Rocha, C.A. Siqueira, A. Garcia, Mater. Sci. Eng. A 361, 111–118 (2003)

W. Kunlin, Z. Qingbo, W. Xingguo, Z. Yunming, J. Mater. Sci. 33, 3573–3577 (1998)

M. Tlotleng, E. Akinlabi, M. Shukla, S. Pityana, Mater. Sci. Eng. C 43, 189–198 (2014)

S. Kumar, S.P. Dwivedi, V.K. Dwivedi, J. Met. Mater. Miner. 30, 67–75 (2020)

S.P. Dwivedi, S. Sharma, S. Sharma, Mater. Perform. Charact. 9, 267 (2020)

S.P. Dwivedi, S. Sharma, T. Singh, N. Kumar, Ann. Chim. Sci. Matér. 44, 281–286 (2020)

B. Singh, S. Zafar, Manuf. Lett. 25, 75–80 (2020)

Funding

There is no funding support in the present study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dwivedi, S.P. Microstructure and Tribo-corrosion Behavior of Stainless Steel-304 Cladding with the Mixture of Nickel and Chromium Carbide by Microwave Energy. J. Inst. Eng. India Ser. D 104, 689–697 (2023). https://doi.org/10.1007/s40033-022-00439-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-022-00439-6