Abstract

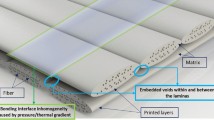

Composite materials are used in place of conventional metals to create complex, homogeneous structures that are lightweight and extremely durable. It has been observed that the curved section of a complex structure is the weakest, with the greatest stress concentration occurring in the L-shaped curved section with uniform thickness. In this work, L-shaped woven carbon fiber-reinforced plastic (CFRP) laminates were fabricated by hand layup method with a stacking sequence of [90°/0°/45°/−45°/90°/0°/45°/−45°]S. The fabricated laminates were experimentally tested under pullout and 4-point bending loads according to ASTM D6415 and modified ASTMD6415, respectively. The average load capacity of the specimen for the pullout test was 496.4 N. For the 4-point bending test, the average load capacity was 857.4 N. A Nikon DSLR camera was used to record the onset and progression of damage. In these tests, matrix cracking occurs mainly before and after the 90° lamina, while delamination occurs mainly at the 0°/45°, 90°/0°, and 45°/0° interfaces. This is due to the fact that in the 4-point bending test, the maximum compressive stresses occur in the contact area and the stresses are transmitted through the matrix to the fiber. An optical microscope was used to examine the microstructures of the specimens before and after the experimental tests. It was found that the failure was caused by cracks in the matrix leading to delamination failure. Other failures such as fiber breakage, cracks in the matrix, fiber splitting, and delamination were also observed with the optical microscope.

Similar content being viewed by others

References

S. Bati, T. Briccoli, Rotunno, Histor. Constr. 1039: 46, (2001). http://www.hms.civil.uminho.pt/events/historica2001/page%201039-1046%20_114_pdf

D. Ozkan, M.S. Gok, A.C. Karaoglanli, Engineering Design Applications III (Springer, Cham, 2020), pp.235–253

M. Balasubramanian, Composite materials and processing (CRC Press, Boca Raton, 2014), pp.335–343

D.P. Archana, H.N. Jagannatha Reddy, J. Prabhakara, Inst. Eng. India Ser. C 103, 39–52 (2022). https://doi.org/10.1007/s40032-021-00743-2

A. Janakiraman, S. Pemmasani, J. Sheth, Inst. Eng. India Ser. C 101, 291–302 (2020). https://doi.org/10.1007/s40032-020-00563-w

M.M. Bordoloi, S. Kirtania, J. Banerjee, Inst. Eng. India Ser. D (2022). https://doi.org/10.1007/s40033-022-00380-8

T.W. Clyne, D. Hull, An introduction to composite materials (Cambridge University Press, England, 2019)

Tong, Ruoshi, PhD diss., Concordia Univ., (2012). http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.634.3187&rep=rep1&type=pdf

I. Uyar, B. Gozluklu, D. Coker, In J. Phys. Conf. Ser. (2014). https://doi.org/10.1088/17426596/524/1/012042

R.M. Jones, CRC Press (2018). https://doi.org/10.1201/9781498711067

N. Zahlan, J.M. O’neill, Composites 20(1), 77–81 (1989). https://doi.org/10.1016/0010-4361(89)90685-x

H.W. Wiersma, L.J.B. Peeters, R. Akkerman, Compos. Part A: Appl. Sci. Manuf. 29(11), 1333–1342 (1998). https://doi.org/10.1016/S1359-835X(98)00062-1

S.B. Tibhe, V.R. Rathi, Procedia Technol. 24, 140–147 (2016). https://doi.org/10.1016/j.protcy.2016.05.020

K.T. Le, K. Lee, Compos. Part B: Eng. (2006). https://doi.org/10.1016/j.compositesb.2009.06.005

Z.E. Benzeguir, G.-S. Abidine, O. Chaallal, J. Compos. Constr. 24(4), 04020031 (2020). https://doi.org/10.1061/(ASCE)CC.1943-5614.0001045

D. Çöker, J. Phys.: Conf. Ser. (2015). https://doi.org/10.1088/1742-6596/524/1/012042

T. Matsuo, T. Goto, J. Takahashi, Adv. Compos. Mater 24(3), 249–268 (2015). https://doi.org/10.1080/09243046.2014.886754

Q. Guo, I. Ohsawa, J. Takahashi, Adv. Compos. Mater (2019). https://doi.org/10.1080/09243046.2019.1576011

Q. Zhang, X. Cheng, J. Zhang, S. Wang, Y. Cheng, T. Zhang, Compos. Part B: Eng. 107, 75–83 (2016)

G. Tushar, D. Shah, S.J. Joshi, K.M. Patel, IOP Conf. Ser.: Mater. Sci. Eng. 561(1), 012074 (2019). https://doi.org/10.1088/1757-899X/561/1/012074

P.K. Mishra, A.K. Pradhan, M.K. Pandit, J. Adhes. Sci. Tech. 30(7), 708–728 (2016). https://doi.org/10.1080/01694243.2015.1121851

W. Yi, T. Matsuo, I. Ohsawa, J. Takahashi, J. Reinf. Plast. Compos. 33(14), 1305–1315 (2014)

B.K. Chaurasia, D. Kumar, V.A. Maheshbhai, Recent Advances in Manufacturing, Automation, Design and Energy Technologies (Springer, Singapore, 2022), pp.693–703

A. Guenanou, A. Houmat, Eng. Optim. 50(5), 766–780 (2018). https://doi.org/10.1080/0305215X.2017.1347924

Van Tho, Hoang, Young Jin Yum, 2158–2161, (2014). https://www.dbpia.co.kr/Journal/articleDetail?nodeId=NODE06069776

H.Y. Choi, H.S. Wang, F.-K. Chang, J. Comp. Mater. 26(6), 804–827 (1992)

S.Y. Kandukuri, A. Pai, J. Manikandan, Inst. Eng. India Ser. C 103, 939–948 (2022). https://doi.org/10.1007/s40032-022-00808-w

T. Ouyang, W. Sun, Z. Guan, R. Tan, Z. Li, Compos. Struct. 206, 791–800 (2018). https://doi.org/10.1016/j.compstruct.2018.08.080

P. Carrara, D. Ferretti, F. Freddi, Compos. B Eng. 45(1), 800–810 (2013). https://doi.org/10.1016/j.compositesb.2012.04.029

da Silva, C. A. N., J. Ciambella, Joaquim AO Barros, I. G. Costa (2018). https://repositorium.sdum.uminho.pt/bitstream/1822/72175/1/IC_207.pdf

T.N. Geleta, K. Woo, B.K. Lee, Int. J. Aeronaut. Space Sci. 19, 363–374 (2018). https://doi.org/10.1007/s42405-018-0038-y

Z.Y. Pan, Q.F. Duan, Y.C. Zhong, S.X. Li, D.F. Cao, Strength Mater. 50(1), 203–210 (2018). https://doi.org/10.1007/s11223-018-9960-2

E. Kappel, D. Stefaniak, C. Hühne, Compos. Struct. 106, 615–625 (2013). https://doi.org/10.1016/j.compstruct.2013.07.020

G. Pitarresi, U. Galietti, Strain 46(5), 446–459 (2010). https://doi.org/10.1111/j.1475-1305.2009.00660.x

Z. Yang, J. Zhang, Y. Xie, B. Zhang, B. Sun, H. Guo, Appl. Comp. Mater. 24(6), 1447–1458 (2017)

A. Makeev, G. Seon, Y. Nikishkov, E. Lee, J. Comp. Mater. 49(7), 783–794 (2001). https://doi.org/10.1177/0021998314525979

Acknowledgements

The author wishes to thank the Department of Mechanical Engineering, National Institute of Technology Jamshedpur, Inida, Ms Soma PUF Metal Pvt. Ltd., Jamshedpur and Auto Cluster Jamshedpur for providing facilities and necessary support in fabricating composite laminates and conducting experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare(s) that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaurasia, B.K., Kumar, D. & Paswan, M.K. Experimental Studies of Failure in L-Shaped Carbon Fiber-Reinforced Polymer Composite Under Pullout and Four-Point Bending. J. Inst. Eng. India Ser. D 104, 569–579 (2023). https://doi.org/10.1007/s40033-022-00411-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-022-00411-4