Abstract

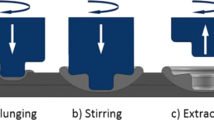

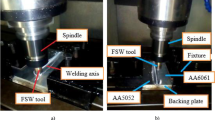

Aluminium alloy AA2219 offers excellent weldability due to its low sensitivity to hot cracking, although it has inadequate weld joint strength. The reduction in the alloy's strength is mainly due to the melting and solidification process. The process parameters that influence the thermomechanical and metallurgical events that occur during welding are primarily responsible for the weld quality. The main objective of this study is to improve tensile strength and corrosion resistance by adopting post weld heat treatment. The influence of post weld heat treatment on the characteristics of AA2219-T87 aluminium alloy welded by gas tungsten arc (GTA), electron beam (EB), and friction stir (FS) processes was discussed in this paper. Experimentation was planned by utilizing a Box-Behnken design of experiments. Square butt joints were fabricated at planned experimental conditions, and samples were prepared for analysis. Response surface methodology (RSM) was employed and used to formulate mathematical models that incorporate welding process parameters to anticipate properties. A global optimization algorithm, simulated annealing (SA), was used to perform multi-objective optimization. For optimized welded samples, post weld heat treatment was shown. The findings indicate that post weld heat treatment improves the strength and corrosion resistance of AA2219-T87 aluminium alloy.

Similar content being viewed by others

References

T. Dursun, C. Soutis, Recent developments in advanced aircraft aluminium alloys. Mater. Des. 1980–2015(56), 862–871 (2014). https://doi.org/10.1016/j.matdes.2013.12.002

S.R. KoteswaraRao, G. Madhusudhan Reddy, K. SrinivasaRao, P. SrinivasaRao, M. Kamaraj, K. Prasad Rao, Gas tungsten arc welded AA2219 alloy using scandium containing fillers mechanical and corrosion behavior. Trans Ind Inst Metals 57(5), 451–459 (2004)

R.K. Gupta, S.V.S.N. Murty, Analysis of crack in aluminium alloy AA2219 weldment. Eng. Fail. Anal. 13(8), 1370–1375 (2006). https://doi.org/10.1016/j.engfailanal.2005.10.009

S. Arunkumar, P. Rangarajan, K. Devakumaran, P. Sathiya, Comparative study on transverse shrinkage, mechanical and metallurgical properties of AA2219 aluminium weld joints prepared by gas tungsten arc and gas metal arc welding processes. Defence technology 11(3), 262–268 (2015). https://doi.org/10.1016/j.dt.2015.05.008

S.R.K. Rao, G. Madhusudhan Reddy, K. Prasad Rao, Effects of thermo-mechanical treatments on mechanical properties of AA2219 gas tungsten arc welds. J. Mater. Process. Technol. 202(1–3), 283–289 (2008). https://doi.org/10.1016/j.jmatprotec.2007.08.070

S. Malarvizhi, K. Raghukandan, N. Viswanathan, Effect of post weld aging treatment on tensile properties of electron beam welded AA2219 aluminum alloy. Int. J. Adv. Manuf. Technol. 37(3), 294–301 (2008). https://doi.org/10.1007/s00170-007-0970-7

S. Malarvizhi, V. Balasubramanian, Effect of welding processes on AA2219 aluminium alloy joint properties. Trans. Nonferrous Metals Soc. China 21(5), 962–973 (2011). https://doi.org/10.1016/S1003-6326(11)60808-X

B.S. Nair, G. Phanikumar, K. Prasad Rao, P.P. Sinha, Improvement of mechanical properties of gas tungsten arc and electron beam welded AA2219 (Al–6 wt-% Cu) alloy. Sci. Technol. Weld. Join. 12(7), 579–585 (2007). https://doi.org/10.1179/174329307X227210

Z.Y. Zhu, C.Y. Deng, Y. Wang, Z.W. Yang, J.K. Ding, D.P. Wang, Effect of post weld heat treatment on the microstructure and corrosion behavior of AA2219 aluminum alloy joints welded by variable polarity tungsten inert gas welding. Mate. Des. (1980–585) 65, 1075–1082 (2015). https://doi.org/10.1016/j.matdes.2014.10.056

J. Ding, D. Wang, W.A.N.G. Ying, D.U. Hui, Effect of post weld heat treatment on properties of variable polarity TIG welded AA2219 aluminium alloy joints. Trans. Nonferrous Metals Soc. China 24(5), 1307–1316 (2014). https://doi.org/10.1016/S1003-6326(14)63193-9

C. Sharma, D.K. Dwivedi, P. Kumar, Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al–Zn–Mg alloy AA7039. Mater. Des. 43, 134–143 (2013). https://doi.org/10.1016/j.matdes.2012.06.018

R.A. Johnson, Probability and Statistics for Engineers (Landon, Pearson, 2018)

D.C. Montgomery, Design and analysis of experiments (John wiley & sons, New Jersey, 2017)

S. Malarvizhi, V. Balasubramanian, Influences of welding processes and post-weld ageing treatment on mechanical and metallurgical properties of AA2219 aluminium alloy joints. Weld. World 56(9), 105–119 (2012). https://doi.org/10.1007/BF03321386

D. Delahaye, S. Chaimatanan, M. Mongeau, Simulated annealing: From basics to applications (Springer, Cham, In Handbook of metaheuristics, 2019). https://doi.org/10.1007/978-3-319-91086-4_1

A. El Hami, P. Pougnet (eds.), Embedded Mechatronic Systems 2: Analysis of Failures Modeling, Simulation and Optimization (Elsevier, Amsterdam, 2020). https://doi.org/10.1016/C2016-0-01030-6

Acknowledgements

This work was supported in part by the Department of Metallurgical Engineering, Andhra University, Visakhapatnam, India.

Funding

No funding was provided for the completion of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajnaveen, B., Rambabu, G., Prakash, K. et al. A Mathematical and Experimental Approach to Improve Strength and Corrosion Resistance of Gas Tungsten Arc, Electron Beam and Friction Stir Welded AA2219-T87 Al-Alloy. J. Inst. Eng. India Ser. D 104, 1–13 (2023). https://doi.org/10.1007/s40033-022-00368-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-022-00368-4