Abstract

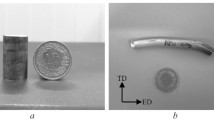

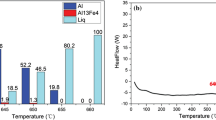

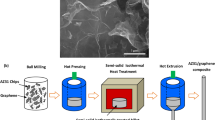

In the present work, an Al4032 alloy reinforced with various contents of graphene (0, 1, 3, 5 wt.%) was fabricated via stir casting and an 8 h homogenization process. The Al4032–graphene composites were severely deformed by equal channel angular pressing (ECAP). The microstructure and fractography of composites at different processing stages have been investigated using optical microscopy and scanning electronic microscopy. The results reveal that the graphene sheets were dispersed homogeneously and Al4032 matrix grains were significantly refined with ECAP process. Moreover, the agglomeration of reinforcement with the addition of 3% and 5% of graphene in matrix alloy is also refined and bounded in the grain boundaries. The composites mechanical properties were assessed as a function of the number of passes in ECAP process. After 6 runs of ECAP, the hardness and tensile characteristics of the material improved considerably.

Similar content being viewed by others

References

H. Azar, B. Sadri, A. Nemati et al., Investigating the microstructure and mechanical properties of aluminum-matrix reinforced-graphene nanosheet composites fabricated by mechanical milling and equal-channel angular pressing. Nanomaterials 9, 1070 (2019). https://doi.org/10.3390/nano9081070

A. Bisht, M. Srivastava, R. Manoj, I. Lahiri, D. Lahiri, Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering. Mater. Sci. Eng., A 695, 20–28 (2017). https://doi.org/10.1016/j.msea.2017.04.009

M. Bodunrin, K. Alaneme, L. Chown, Aluminium matrix hybrid composites: a review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Market. Res. 4, 434–445 (2015). https://doi.org/10.1016/j.jmrt.2015.05.003

V. Chak, H. Chattopadhyay, Fabrication and heat treatment of graphene nanoplatelets reinforced aluminium nanocomposites. Mater. Sci. Eng., A 791, 139657 (2020). https://doi.org/10.1016/j.msea.2020.139657

A. Chidambaram, S.B. Prabu, K.A. Padmanabhan, Microstructure and mechanical properties of AA6061–5wt.%TiB2 in-situ metal matrix composite subjected to equal channel angular pressing. Mater. Sci. Eng., A 759, 762–769 (2019). https://doi.org/10.1016/j.msea.2019.05.068

S. Das, S. Khanna, D.P. Mondal, Graphene-reinforced aluminum hybrid foam: response to high strain rate deformation. J. of Materi Eng and Perform 28, 526–534 (2019). https://doi.org/10.1007/s11665-018-3815-7

K. Deepak. et al. (2021). Morphological and mechanical characterization of Al-4032/SiC/GMP hybrid composites. https://www.researchsquare.com/article/rs-232039/v1

R. Derakhshandeh-Haghighi, S.A. JenabaliJahromi, The effect of multi-pass equal-channel angular pressing (ecap) for consolidation of aluminum-nano alumina composite powder on wear resistance. J. of Mater Eng Perform 25, 687–696 (2016). https://doi.org/10.1007/s11665-016-1888-8

E. Ghasali, P. Sangpour, A. Jam et al., Microwave and spark plasma sintering of carbon nanotube and graphene reinforced aluminum matrix composite. Archiv. Civ. Mech. Eng 18, 1042–1054 (2018). https://doi.org/10.1016/j.acme.2018.02.006

Z. Horita, K. Oh-ishi, K. Kaneko, Microstructure control using severe plastic deformation. Sci. Technol. Adv. Mater. 7, 649–654 (2006). https://doi.org/10.1016/j.stam.2006.05.011

D. Hülya, G. Canser, Ç. Nilay, Y. Melis, An investigation into the wear behavior of aged Alumix321/SiC composites fabricated by hot pressing. Rev. Metal. 55(3), e148 (2019). https://doi.org/10.3989/revmetalm.148

C. Jeon, Y. Jeong, J. Seo et al., Material properties of graphene/aluminum metal matrix composites fabricated by friction stir processing. Int. J. Precis. Eng. Manuf 15, 1235–1239 (2014). https://doi.org/10.1007/s12541-014-0462-2

Md. Khan, R.U. Din, A. Wadood et al., Effect of graphene nanoplatelets on the physical and mechanical properties of Al6061 in fabricated and T6 thermal conditions. J. Alloy. Compd. 790, 1076–1091 (2019). https://doi.org/10.1016/j.jallcom.2019.03.222

P.K. Kumar et al., Effect of compaction pressure on mechanical properties of powder steel 0.06% C – 22% Cr – 13% Ni – 5% Mn – 2% Mo obtained by mechanical alloying followed by annealing. Met Sci Heat Treat 63, 132–139 (2021). https://doi.org/10.1007/s11041-021-00659-9

P.K. Kumar, N.V. Sai, A.G. Krishna, Influence of sintering conditions on microstructure and mechanical properties of alloy 218 steels by powder metallurgy route. Arab. J. Sci. Eng. 10, 116–121 (2018). https://doi.org/10.1007/s13369-017-3015-z

K. Kumar et al., Effect of Y2O3 addition and cooling rate on mechanical properties of Fe-24Cr-20Ni-2Mn steels by powder metallurgy route. Compos. commun 10, 116–121 (2018). https://doi.org/10.1016/j.coco.2018.09.003

D. Kumar, K.S. Pradeep, Microstructural and mechanical characterization of Al-4032 based metal matrix composites. Mater Today: Proc 18, 2563–2572 (2019). https://doi.org/10.1016/j.matpr.2019.07.114

F.H. Latief, El. Sayed, M. Sherif, Effects of sintering temperature and graphite addition on the mechanical properties of aluminum. J. Ind. Eng. Chem. 18, 2129–2134 (2012). https://doi.org/10.1016/j.jiec.2012.06.007

T.M. Lillo, Enhancing ductility of AL6061+10wt.% B4C through equal-channel angular extrusion processing. Mater. Sci. Eng., A 410, 443–446 (2005). https://doi.org/10.1016/j.msea.2005.08.093

J. Liu, U. Khan et al., Graphene oxide and graphene nanosheet reinforced aluminium matrix composites: powder synthesis and prepared composite characteristics. Mater. Des. 94, 87–94 (2016). https://doi.org/10.1016/j.matdes.2016.01.031

G.K. Manjunath, G.V. Preetham Kumar, K. Udaya Bhat et al., Microstructure and mechanical properties of cast Al-5Zn-2Mg alloy subjected to equal-channel angular pressing. J Mater Eng and Perform 27, 5644–5655 (2018). https://doi.org/10.1007/s11665-018-3691-1

L.F. Mondolfo, Aluminium Alloys, Butterworths & Co Ltd, Elsevier. https://www.elsevier.com/books/aluminum-alloys/mondolfo/978-0-408-70932-3 (1976)

L.K. Pillari et al., Processing and characterization of graphene and multi-wall carbon nanotube-reinforced aluminium alloy AA2219 composites processed by ball milling and vacuum hot pressing. Metallogr. Microstruct. Anal. 6, 289–303 (2017). https://doi.org/10.1007/s13632-017-0365-6

R. Raj, J.M.S. YoganandhSaravanan et al., Effect of graphene addition on the mechanical characteristics of AA7075 aluminium nanocomposites. Carbon Lett (2020). https://doi.org/10.1007/s42823-020-00157-7

N.V. Rengasamy et al., An analysis of mechanical properties and optimization of edm process parameters of Al 4032 alloy reinforced with Zrb2 and Tib2 In-Situ composites. J. Alloy. Compd. 662, 325–338 (2016). https://doi.org/10.1016/j.jallcom.2015.12.023

M.R. Rezaei, S.G. Shabestari, S.H. Razavi, Effect of ECAP consolidation process on the interfacial characteristics of Al-Cu-Ti metallic glass reinforced aluminum matrix composite. Compos. Interfaces 25, 669–679 (2018). https://doi.org/10.1080/09276440.2018.1439619

M. Saravanan, R.M. Pillai, K.R. Ravi, B.C. Pai, M. Brahmakumar, Development of ultrafine grain aluminium–graphite metal matrix composite by equal channel angular pressing. Compos. Sci. Technol. 67, 1275–1279 (2007). https://doi.org/10.1016/j.compscitech.2006.10.003

S.E. Shin, D.H. Bae, Deformation behavior of aluminum alloy matrix composites reinforced with few-layer graphene. Compos. A Appl. Sci. Manuf. 78, 42–47 (2015). https://doi.org/10.1016/j.compositesa.2015.08.001

S. Soltani, R.R.T. KhosroshahiMousavian et al., Stir casting process for manufacture of Al–SiC composites. Rare Met. 36, 581–590 (2017). https://doi.org/10.1007/s12598-015-0565-7

V. Subbaiah, B. Palampalle, K. Brahmaraju, Microstructural analysis and mechanical properties of pure Al–GNPs composites by stir casting method. J. Inst. Eng. India Ser. C 100, 493–500 (2019). https://doi.org/10.1007/s40032-018-0491-1

Y.P. Sun, J. Han, Y. Tu, Z. Bai, Y.Q. He, Microstructure and mechanical properties of a spray deposited SiCp/Al composite processed by hot extrusion and equal channel angular pressing. Mater. Res. Innovations 18, 220–223 (2014). https://doi.org/10.1179/1432891714Z.000000000687

T. Tański, P. Snopiński, W. Borek, Strength and structure of AlMg3 alloy after ECAP and post-ECAP processing. Mater. Manuf. Processes 32, 1368–1374 (2017). https://doi.org/10.1080/10426914.2016.1257131

Ç. Uğur, G. Turkey, Nano platelets reinforced a composite fabricated through ultra-high frequency induction sintering. Rev. Metal. 57(1), e188 (2021). https://doi.org/10.3989/revmetalm.188

M. Venkatasudhahar et al., Influence of stacking sequence and fiber treatment on mechanical properties of carbon-jute-banana reinforced epoxy hybrid composites. Int. J. Polym. Anal. Charact. 25, 238–251 (2020). https://doi.org/10.1080/1023666X.2020.1781481

R. Vignesh, R. Harichandran, U. Vignesh, M. Thangavel, S.B. Chandrasekhar, Influence of hot extrusion on strain hardening behaviour of graphene platelets dispersed aluminium composites. J. Alloy. Compd. 855, 157448 (2021). https://doi.org/10.1016/j.jallcom.2020.157448

J. Wang, Z. Li, G. Fan, H. Pan, Z. Chen, D. Zhang, Reinforcement with graphene nanosheets in aluminum matrix composites. Scripta Mater. 66, 594–597 (2012). https://doi.org/10.1016/j.scriptamat.2012.01.012

A. Warner, J. Bell, T. Stephenson, Opportunities for new graphitic aluminium metal matrix composite. Mater. Sci. Technol. 14, 843–850 (1998). https://doi.org/10.1179/mst.1998.14.9-10.843

Acknowledgements

The authors would like to thank Anna University College of Engineering, Chennai, India, for providing ECAP and mechanical testing facilities. The SEM analysis in the present investigation was carried out at the Indian Institute of Technology Madras (IITM), India.

Funding

Funding is not applicable to this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Krishnarao, R.S., Veeranna, V. & Krishna, A.G. Influence of Graphene Addition on Microstructure and Mechanical Properties of Homogenized Al4032–Graphene Composites Processed Through ECAP. J. Inst. Eng. India Ser. D 103, 203–216 (2022). https://doi.org/10.1007/s40033-021-00322-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-021-00322-w