Abstract

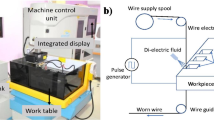

Lightweight material such as aluminum-based metal matrix composites (MMC) is extensively used in automobile, aerospace, and some other precise engineering applications. For such material, the processing is not simple due to the presence of some other material in the aluminum. To overcome this, wire electrical discharge machining (WEDM) is projected for cutting of aluminum–graphite (10%) metal matrix composite with variation in process parameters. In present work, the technique for order of preference by similarity to ideal solution (TOPSIS) and an adaptive neuro-fuzzy inference system (ANFIS) is employed to assess the WEDM of AlGrCp10 MMC. Taguchi’s L27 orthogonal array was adopted for the experimentation. The influence of process variables, pulse on time (PON), pulse off time (POFF), the feed rate of wire (WFR), and the tension in the wire (WT), is considered for overall performance measure. The overall performance is measured in terms of the responses such as material removal rate (MRR), overcut (OVT), and surface roughness (Ra). Analysis of variance, i.e., ANOVA, is performed to find out the most influencing process parameters. TOPSIS-ANFIS predicted results are tested for the confirmation tests which show an enhancement of overall closeness coefficient increases from 0.656793 to 0.772138. The optimum setting obtained for the overall performance is pulse on time = 112 μs pulse off time = 56 μs, wire feed rate = 12 m/min, and wire tension of 1.2 kg.

Similar content being viewed by others

References

N. Chakala, P. Subhash, P, S. Chandrabose, C. Rao, Optimisation of WEDM parameters on Nitinol alloy using RSM and desirability approach. Aus. J. Mech. Engg.1–14(2014). https://doi.org/10.1080/14484846.2019.1681239

S. Chia-Chi, A performance evaluation model by integrating fuzzy AHP and fuzzy TOPSIS method. Exp. Sys. App. 37:7745–7754 (2010). https://doi.org/10.1016/j.eswa.2010.04.066.

A. Goswami, J. Kumar, Optimization of wire-cut EDM of Nimonic-80A using Taguchi approach and utility concept. Eng Sci. Tech. Int. J. 17(2), 236–246 (2014)

N. Huu-Phan, P. Van-Dong, N. Ngoc-Vu, Application of TOPSIS to Taguchi method for multi-characteristic optimization of electrical discharge machining with titanium powder mixed into dielectric fluid. Int. J. Adv. Manuf. Tech. 98, 1179–1198 (2018). https://doi.org/10.1007/s00170-018-2321-2

M. Jenarthanani, R. Jeyapaul, Optimization of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int. J. of Engg. Sci. Tech. 5(4), 23–36 (2013).

V. Kavimani, K.S. Prakash, T. Thankachan, Multi-objective optimization Graphene–SiC Magnesium composite through hybrid techniques. Measurt. 145, 335–349 (2019)

H. Majumdar, K. Maity, Prediction and optimization of surface roughness and micro hardness using GRNN and MOORA—fuzzy—a MCDM approach Nitinol in WEDM. Measuret.118, 123 (2018).

J. Mevada, A comparative experimental investigation on process parameters using Molybdenum, Brass and Zinc-Coated wires in wire cut EDM. Int. J. Sci. Eng. Res. 4(7), 1398–1407 (2013).

H. Nguyen, N. Ngo, & Q. Nguyen, Optimizing process parameters in EDM using low frequency vibration for material removal rate and surface roughness. J. King Saud Uni. Eng. Sci.(2020). https://doi.org/10.1016/j.jksues.2020.05.002

M. Phate, S. Toney, Modeling and prediction of WEDM performance parameters for Al/SiCp MMC using dimensional analysis and artificial neural network. Eng. Sci. Tech. Int. J. 22 (2), 468–476 (2019). https://doi.org/10.1016/j.jestch.2018.12.002

M. Phate, S. Toney, V. Phate, Analysis of machining parameters in WEDM of Al/Sicp20 MMC using Taguchi-based Grey–Fuzzy Approach. Hindawi’s, Model. Sim. Eng., 1–13. (2019). https://doi.org/10.1155/2019/1483169.

M. Phate, S.Toney, V. Phate, Optimization performance parameters of ohns die steel using dimensional analysis integrated with Desirability function. Int. J. Ind. Eng. Prod. Res. 30 (1), 11–23 (2019). http://ijiepr.iust.ac.ir/article-1-877-en.html.

V. Phate, R. Malmathanraj, P. Palanisamy, Classification and weighing of sweet lime (Citrus limetta) for packaging using computer vision system. J. Food Meas. Characterization 13, 1451–1468 (2019). https://doi.org/10.1007/s11694-019-00061-3

V.Phate, R.Malmathanraj, P. Palanisamy, Clustered ANFIS weighing of sweet lime (Citrus limetta) for packaging using computer vision system. J. Food Proc. Eng.1–16 (2019). https://doi.org/10.1111/jfpe.13160

R. Pujara, K. Ramji, S. Beela, Effect of wire EDM conditions on generation of residual stresses in machining of aluminum 2014T6 alloy. Alex. Eng. J. 55, 1077–1084 (2016). https://doi.org/10.1016/j.aej.2016.03.014

J. Katebi, M. Shoaei, M. Shariati, T. Thoi, M. Khorami, Developed of comparative analysis of metaheuristic optimization algorithms for optimal active control of structures. Eng. Comps. (2019). https://doi.org/10.1007/s00366-019-00780-7

V. Kumar, K. Vikas, J. Kamal, An experimental analysis and optimization of machining rate and surface characteristics in WEDM of Monel-400 using RSM and desirability approach. J. Ind. Eng. Int. 11, 297–307 (2015). https://doi.org/10.1007/s40092-015-0103-0

M. Kolli, K. Adepu, Effect of dielectric fluid with surfactant and graphite powder on electrical discharge machining of titanium alloy using Taguchi method. Eng. Sci. Tech. Int. J. 18, 524–535 (2015). https://doi.org/10.1016/j.jestch.2015.03.009

E. Mussada, C. Choo, P. Kameswari, Surface harden ability studies of the die steel machined by WEDM (2019). https://doi.org/10.1007/s00366-019-00780-7

R. Nadda, R. Kumar, T.Singh, R. Chauhan, A. Patnaik. B. Gangi, Experimental investigation and optimization of cobalt bonded tungsten carbide composite by hybrid AHP-TOPSIS approach. Alex. Engg. J. 57, 3419–3428 (2018). https://doi.org/10.1016/j.aej.2018.07.013

S. Naina , P. Sihag, S. Luthrac. Performance evaluation of fuzzy-logic and BP-ANN methods for WEDM of aeronautic super alloy. Meths.X, 5:890–908 (2018). https://doi.org/10.1016/j.mex.2018.04.006

A.Satpathy, S. Tripathy, P. Senapati. Optimization of EDM process parameters for AlSiC-20% SiC reinforced metal matrix composite with multi response using TOPSIS. Matrs. Today Proce. 4(2)Part A, 3043–3052 (2017). https://doi.org/10.1016/j.matpr.2017.02.187

S.K. Tamang, M. Chandrashekaran, Modelling and optimization for parameters for minimizing surface roughness and tool wear in turning Al/SiC MMC using conventional and soft computing techniques. Adv. Prod. Eng. Mangts. 10(2), 59–72 (2015)

M. Phate, S. Toney, V. Phate, Modelling and investigating the impact of EDM parameters on surface roughness in EDM of Al/Cu/Ni Alloy. Aus. J. Mech. Eng. https://doi.org/10.1080/14484846.2020.1790478 (2020)

M. Phate, S. Toney, V. Phate, Multi-parametric optimization of WEDM using Artificial neural network (ANN)-based PCA for Al/SiCp MMC. J. Inst. Eng. India Ser. C https://doi.org/10.1007/s40032-020-00615-1(2020)

Acknowledgements

The authors would like to express their gratitude toward all family members and friends for their support.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Phate, M., Toney, S., Phate, V. et al. Multi-Response Optimization of Al/GrCp10 MMC Performance in WEDM Using Integrated TOPSIS-ANFIS Approach. J. Inst. Eng. India Ser. D 103, 249–261 (2022). https://doi.org/10.1007/s40033-021-00302-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-021-00302-0