Abstract

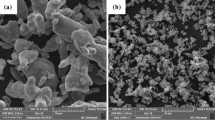

Strain hardening behaviour has significant effect on altering the properties of materials. In the present study, Al–ZrB2 metal matrix composites are made through powder metallurgy route. Incremental weight percentage (wt%) of ZrB2 (0, 2, 4 and 6 wt%) are added to Aluminium matrix to produce different composites. The homogenous powder mixture is compacted and pressurelessly sintered. Sintering of composites is performed over a range of 450–575 °C. The optimized sintered condition is observed at 550 °C for 1 h in controlled atmosphere (argon gas flow). The sintered compacts are strained in incremental steps in different levels up to failure. A visible crack on the bulge of the powder preform is considered as the failure. Composites are strain hardened up to failure. To evaluate the effect of temperature on strain hardening, strain hardening is carried out at different temperatures. Composites are densified with the extent of straining and hardness increases with the increase of strain. Hardness increase with the increase in temperature is maintained during strain hardening. To evaluate the corrosion behaviour of Al–ZrB2 composite, potentiodynamic polarization study are performed on the strained composites. Corrosion rate decrease with the extent of straining.

Similar content being viewed by others

References

S. Ezhil Vannan, S. Paul Vizhian, Microstructure and mechanical properties of as cast aluminum alloy 7075/Basalt dispersed metal matrix composites. J. Miner. Mater. Charact. Eng. 2, 182–193 (2014)

D. Miracle, Metal matrix composites—from science to technological significance. Compos. Sci. Technol. 65, 2526–2540 (2005)

A. Evans, C. Marchi, A. Mortensen, Metal Matrix Composites in Industry: An Introduction and a Survey, vol. 4 (Kluwer Academic Publisher, Dordrecht, 2003), pp. 978–1007

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Particulate reinforced metal matrix composites. J. Mater. Sci. 26, 1137–1156 (1991)

T.W. Chou, A. Kelly, A. Okurat, Composites de Matrices en Métal Renforcés aux Fibres. Composites 16, 183–184 (1985)

A. Kelly, S. Fishman, A. Dhingra, Metal matrix composite, a review, in Proceeding International Symposium on Advances in Cast Reinforced Metal Composite, Chicago

ASM Handbook, Casting, Vol. 15, ASM International (1996)

S. Muniraj, P. Senthil Kumar, Experimental analysis of compressive stress-strain rates and mechanical properites of Al 6061 and Al 6061–SiC. IJLTET 6, 393–397 (2016)

A. Bhandakkar, R.C. Prasad, S.M.L. Sastry, Elastic plastic fracture toughness of aluminium alloy AA6061 flyash composites. Adv. Mat. Lett. 5(9), 525–530 (2014)

C. Neelima Devi, V. Mahesh, N. Selvaraj, Mechanical characterization of aluminium silicon carbide composite. Int. J. Appl. Eng. Res. 1(4), 793–799 (2011)

S. Madhusudan, Mohammed M.M. Sarcar, N.B.R.M. Rao, Mechanical properties of Aluminium–Copper(p) composite metallic materials. J. Appl. Res. Technol. 14, 293–299 (2016)

X. Run, G. Fan, Z. Tan, G. Ji, C. Chen, B. Beausir, D.-B. Xiong, Q. Guo, C. Guo, Z. Li, D. Zhang, Back stress in strain hardening of carbon nanotube/aluminum composites. Mater. Res. Lett. 6(2), 113–120 (2018)

D.R. Kumar, R. Narayanasamy, C. Loganathan, Effect of glass and SiC in aluminum matrix on workability and strain hardening behavior of powder metallurgy hybrid composites. Mater. Des. 34, 120–136 (2012)

D.R. Kumar, R. Narayanasamy, C. Loganathan, Effect of glass in aluminum matrix on workability and strain hardening behavior of powder metallurgy composite. Mater. Des. 32, 2413–2422 (2011)

Di Zhang, Kenjiro Sugio, Kazuyuki Sakai, Hiroshi Fukushima, Osamu Yanagisawa, Effect of volume fraction on the flow behavior of Al–SiC composites considering the spatial distribution of delaminated particles. Mater. Trans. 49(3), 661–670 (2008)

Z. Wang, J. Tan, S. Scudino, B.A. Sun, R.T. Qu, J. He, K.G. Prashanth, W.W. Zhang, Y.Y. Li, J. Eckert, Mechanical behavior of Al-based matrix composites reinforced with Mg58Cu28.5Gd11Ag2.5 metallic glasses. Adv. Powder Technol. 25, 635–639 (2014)

S. Narayan, A. Rajeshkannan, Studies on formability of sintered aluminum composites during hot deformation using strain hardening parameters. J. Mater. Res. Technol. 6(2), 101–107 (2017)

D.W. Wolla, M.J. Davidson, A.K. Khanra, Studies on the formability of powder metallurgical aluminum–copper composite. Mater. Des. 59, 151–159 (2014)

A. Hassani, E. Bagherpour, F. Qods, Influence of pores on workability of porous Al/SiC composites fabricated through powder metallurgy + mechanical alloying. J. Alloy. Compd. 591, 132–142 (2014)

J. Appa Rao, J. Babu Rao, S. Kamaluddin, M.M.M. Sarcar, N.R.M.R. Bhargava, Studies on the workability limits of pure copper using machine vision system and its finite element analysis. Mater. Des. 30, 2143–2151 (2009)

S. Gadakary, R. Veerababu, A.K. Khanra, Workability studies on Cu–TiB2 powder preforms during cold upsetting. Mater. Technol. 50(3), 373–380 (2016)

S.K. Mishra, S.K. Das, L.C. Pathak, Sintering behavior of self-propagating high temperature synthesised ZrB2–Al2O3 composite powder. Mater. Sci. Eng. A 426, 229–234 (2006)

S.K. Mishra, S.K. Das, V. Sherbacov, Fabrication of Al2O3–ZrB2 in situ composite by SHS dynamic compaction: a novel approach. Compos. Sci. Technol. 67, 2447–2453 (2007)

E. Ghasali, A. Pakseresht, F. Safari-Kooshali, M. Agheli, T. Ebadzadeh, Investigation on microstructure and mechanical behavior of Al–ZrB2 composite prepared by microwave and spark plasma sintering. Mater. Sci. Eng., A 627, 27–30 (2015)

D. Zhao, X. Ilu, Y. Liu, X. Bian, In-situ preparation of Al matrix composites reinforced by TiB2 particles and sub-micron ZrB2. J. Mater. Sci. 40, 4365–4368 (2005)

J.B. Foagagnolo, M.H. Robert, E.M. Ruiz-Navas, J.M. Torralba, 6061 Al reinforced with zirconium diboride particles processed by conventional powder metallurgy and mechanical alloying. J. Mater. Sci. 39, 127–132 (2004)

A.K. Khanra, Awareness of materials engineering: an Indian culture perspective. J. Mater. Edu. 39(5–6), 209–222 (2017)

P.D. Reena Kumari, Jagannath Nayak, A. Nityananda Shetty, Corrosion behavior of 6061/Al–15 vol. pct. SiC(p) composite and the base alloy in sodium hydroxide solution. Arab. J. Chem. 9, 1144–1154 (2016)

D. Prabhu, P. Rao, Corrosion behaviour of 6063 aluminium alloy in acidic and in alkaline media. Arab. J. Chem. 10, 2234–2244 (2017)

Acknowledgement

The authors would like to thank Metallurgical and Materials Engineering Department, NIT Warangal which helped in characterization of composites.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaku, S.M.Y., Khanra, A.K. & Davidson, M.J. Strain Hardening Behaviour and Its Effect on Properties of ZrB2 Reinforced Al Composite Prepared by Powder Metallurgy Technique. J. Inst. Eng. India Ser. D 99, 115–124 (2018). https://doi.org/10.1007/s40033-018-0155-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-018-0155-6